Products

Gwell’s extrusion technology satisfies customers with the highest economic efficiency

China’s professional plastic extruder suppliers are always exploring new paths for plastic sheet, film, sheet extruders

PRODUCTS CENTER

For over a decade, GWELL has pioneered advanced extrusion technologies for solar encapsulation films. Our systems produce high-performance EVA, POE, and innovative EPE films that protect solar cells while maximizing module efficiency.

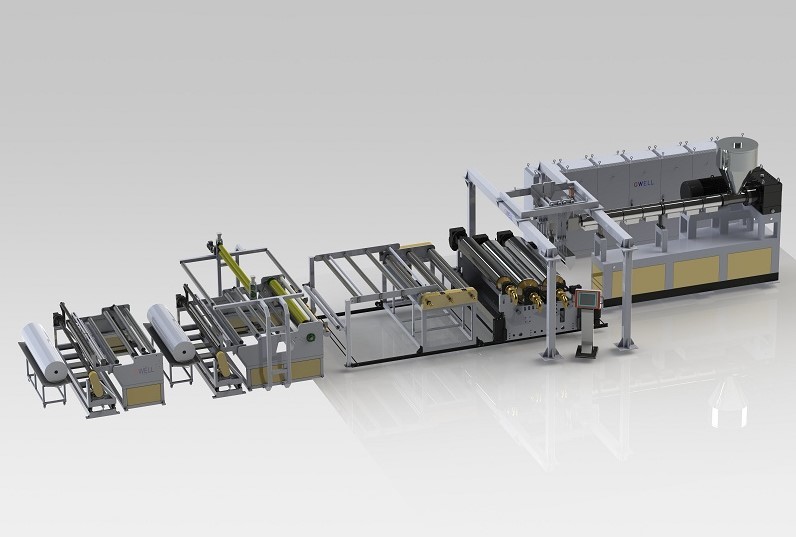

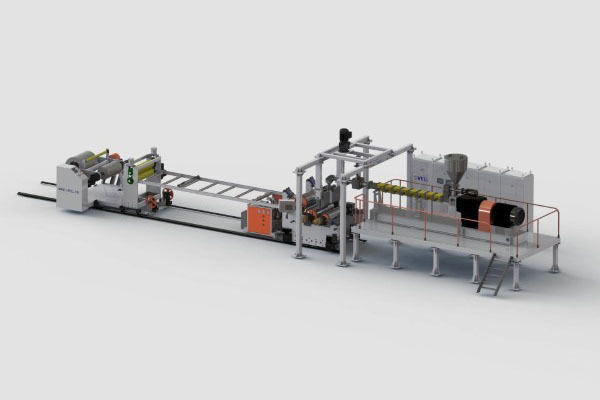

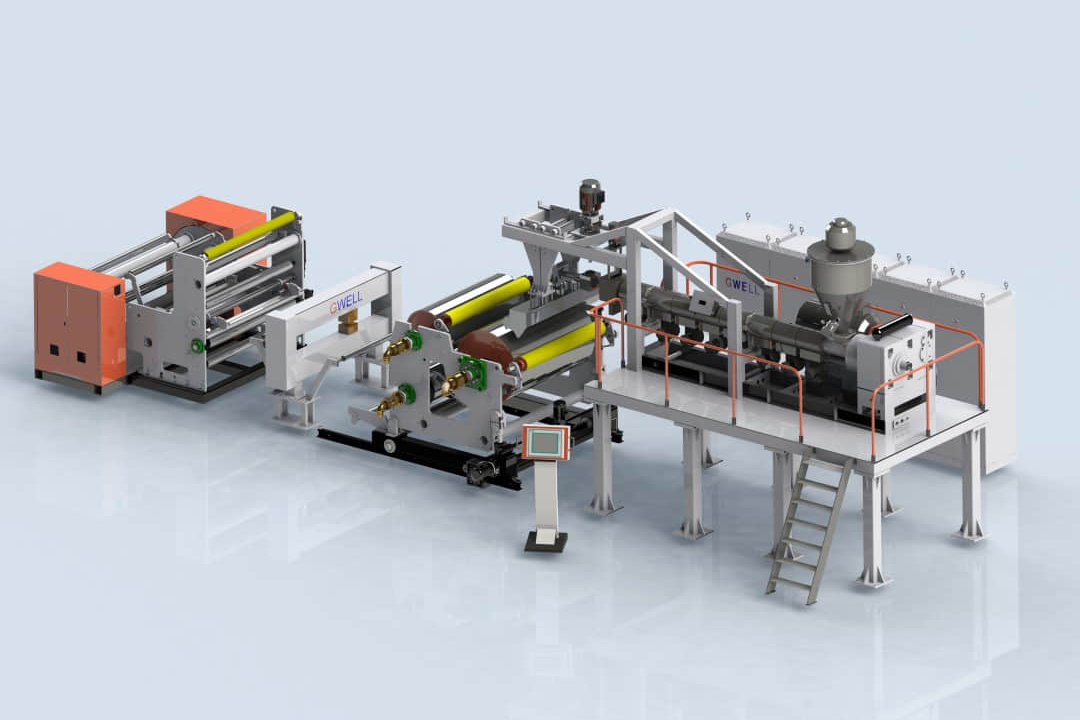

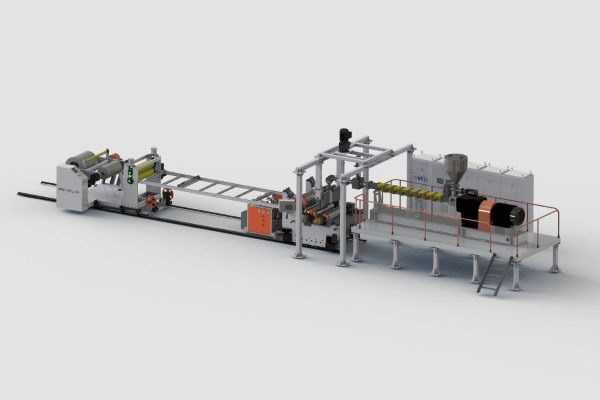

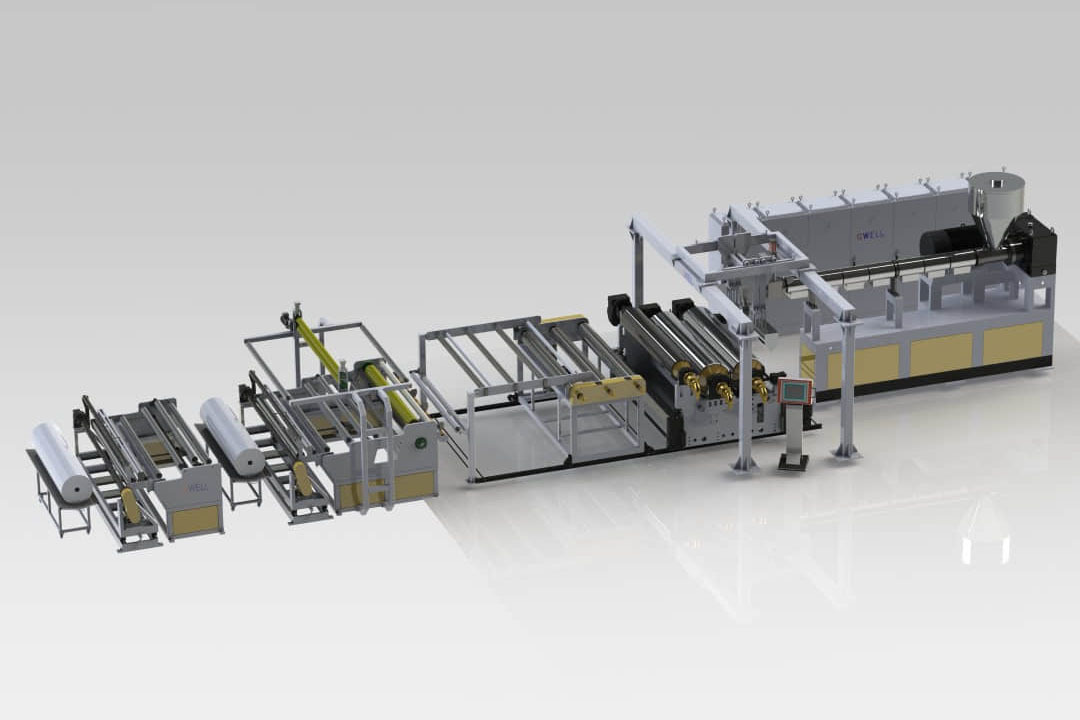

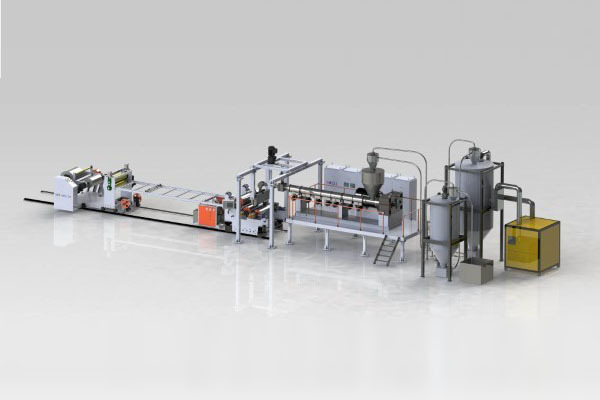

EVA POE Solar PV Encapsulation Film Production Line uses EVA or POE as raw material. The converting process includes material handling, heating, extrusion, calendering, cooling and winding. The production line can be customized according to customer requirements. The film product is a new type of thermosetting hot-melt film, which is not sticky at room temperature and is easy to operate.

EVA POE Cast Film Extrusion Line has an automatic weighing feeding system to ensure high-precision feeding of various solid and liquid additives and raw materials. The low-temperature extrusion system is fully mixed under the premise of ensuring plasticization to prevent cross-linking of additives.

The EVA film production line adopts casting technology to produce EVA solar cell packaging film. The main raw material is vinyl acetate copolymer (EVA), which is formed by heating, casting and extruding after adding additives.

GWELL as China Plastic Extruder Supplier, The EVA POE encapsulation film extrusion line adopts a tape casting process and takes Poe and EVA as the main raw materials to produce POE and EVA encapsulation films, which are mainly used for the encapsulation of crystalline silicon and thin-film solar cell modules. Due to the advantages of POE and EVA encapsulation film in adhesion, aging resistance, and optical properties, it is more and more widely used in battery modules and various optical products.

Prior to the advent of EVA/POE/EPE solar film extrusion lines, market demand primarily focused on separate EVA and POE solar film production equipment. However, growing market volatility and cost pressures drove increasing customer demand for integrated solutions that could combine EVA's performance characteristics with POE's advantages while reducing raw material costs. Responding to these evolving market needs, GWELL - as a leading Chinese plastic extrusion machinery manufacturer - pioneered the world's first EPE solar film extrusion line, a groundbreaking innovation that successfully merged the benefits of both materials while optimizing production economics. This technological breakthrough rapidly gained global recognition and widespread adoption across the solar industry, establishing EPE extrusion lines as the new standard for photovoltaic encapsulation film production.

Our EVA/POE film extrusion lines produce solar cell encapsulation films with superior low-shrinkage properties. GWELL delivers fully integrated production systems - from feeding to calibration - in a single streamlined solution. GWELL Machinery's EVA/POE film extrusion lines hold an unrivaled global leadership position in this specialized field.