ABS HIPS GPPS Sheet Extrusion Line

China Plastic Extruder Supplier ABS HIPS GPPS sheet extrusion line is mainly composed of 120 mainframes and several small mainframes through distributors. Now it has been mass-produced in China. China Plastic Extruder manufacturer – GWELL improves the original equipment technology, and automatically realizes closed-loop control through the host and metering pump, so that the precision and stability of the equipment reach the domestic leading level.

Key words:Sheet Extrusion Line

Category:

Board Extrusion Line

Download:

Description

ABS HIPS GPPS sheet extrusion line mainly consists of 120 mainframes and several small mainframes through distributors. Now it has been mass-produced in China. China Plastic Extruder manufacturer – GWELL improves the original equipment technology, and automatically realizes closed-loop control through the host and metering pump, so that the precision and stability of the equipment reach the domestic leading level.

Through centralized control, China Plastic Extruder Supplier can browse all equipment information on one screen, such as current, pressure, rotational speed, temperature, vacuum pressure, etc., making the operation easier.

GWELL ABS HIPS GPPS sheet extrusion line adopts the international first-line brand Siemens frequency conversion servo control and Ethernet conduction technology control to achieve high efficiency, high precision, high stability and high security. In case of equipment failure, it can quickly locate errors and carry out remote maintenance. Channel level diagnosis and error analysis can be realized through HMI, greatly reducing commissioning and production downtime. High digital system makes debugging easier and maintenance easier.

China Plastic Extruder manufacturer – GWELL has a complete after-sales service system, from equipment installation and commissioning to manufacturing high-quality products, and provides life-long technical support, so that customers have no worries.

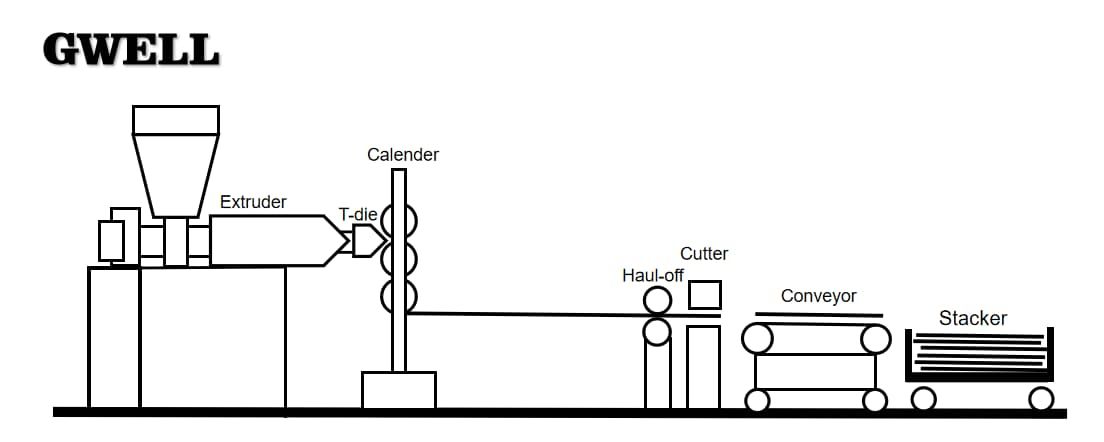

ABS HIPS GPPS sheet extrusion line Product Flows

Extruder —- Screen changer —–Melt pump —– T-die —— Calender —– Cooling bracket —– Haul-off—- Cutter —— Conveyor —– Stacker

Parameter

| Extruder Type | single screw extruder GWS120/GWS65/GWS45 | single screw extruder GWS150/GWS90 | single screw extruder GWS180/GWS105 | parallel twin screw extruder GWP75/ single screw extruder GWS90 |

| Raw material | ABS, PMMA, GPPS, HIPS | |||

| Product structure | A/B/C/B/A, A/B/C, A | A/B/A, A/B, A | A/B/A, A/B, A | A/B/A, A/B, A |

| Net width | 2100mm | |||

| Thickness range | 2-8mm | |||

| Capacity | 600kg/h | 650kg/h | 800kg/h | 800kg/h |

Application

Refrigerator board: it is divided into ABS board, ABS fluorine-free board, ABS antibacterial board, hips high gloss composite board and hips anti-141b composite board. It has strong low-temperature toughness, impact resistance, chemical stability and other good properties. It is mainly used for refrigerator freezer door liner, inner liner, drawer, drainage, water dispenser, etc.

Client

About Gwell

Innovation drives enterprise progress. Relying on the group’s strong technology, equipment strength and innovation spirit, Gwell is committed to the development of high-tech products and the international market. Gwell also actively exchanges and cooperates with world-class scientific research institutions. The new technologies, new processes and new products developed by Gwell are widely used in building materials(PP hollow sheet extrusion machine, PC optic extrusion machine), home appliances(SPC floor extrusion machine), packaging(PET sheet extrusion machine, EVOH film extrusion machine),

medical treatment(PVC rigid sheet extrusion machine), automobiles(TPU film extrusion machine, PVB film extrusion machine), new energy(EVA solar film extrusion machine), aerospace(TPU film extrusion machine), rail transit(waterproof film extrusion machine) and other fields, which are closely related to human life.

Related Product

The main components of the PC Sheet extrusion production line are selected from the world’s high-quality products (such as screws, barrels, rollers, etc.), and its production process is comprehensive. As an excellent supplier of plastic extruders, GWELL’s complete set of production line has approached the world’s high-quality product standards.

As a premier Chinese manufacturer of plastic extrusion machinery, GWELL delivers cutting-edge PS (Polystyrene) Sheet Extrusion Lines engineered for precision, efficiency, and unmatched product consistency. Our advanced extrusion systems are designed to meet the rigorous demands of diverse industries, offering tailored solutions for high-quality PS sheet production.

As a pioneer in PVB interlayer film production machine technology, we specialize in delivering cutting-edge systems designed for high-performance PVB interlayer film manufacturing. Our PVB interlayer film production machines are engineered to meet global industry standards, combining precision, efficiency, and sustainability.

FAQ

What is the main business of GWELL?

Can I go on a field trip to the GWELL factory?

What are the services for purchasing equipment at GWELL?

What types of plastic extrusion machines are available from GWELL?

What is APET PETG CPET Sheet Extrusion Line?

Where does GWELL ship from?

Are there any technical supports for extrusion machine that you need?

Our service will be always at your disposal over the entire extrusion line life.So if you want to know about any other technical supports.Please contact us as soon as possible.