PLA PBS PBAT Starch Straw Sheet Extrusion Line

GWELL as China Plastic Extruder Supplier, PLA PBS PBAT Starch Straw Sheet Extrusion Line is suitable for PLA (PLA) and modified PLA. The whole machine is controlled by PLC, and functions such as actual parameter setting, data operation, feedback, and alarm are automated. Using multi-extruder co-extrusion technology, multi-layer co-extrusion composite PLA or starch sheets can be produced. Widely used in thermoforming, printing, metal packaging, etc.

Key words:Sheet Extrusion Line

Category:

Sheet Extrusion Line

Download:

Description

Features of PLA sheet extrusion line

- It is suitable for the production of PLA polylactic acid starch-based fully biodegradable sheet, with high output, low energy consumption and simple operation.

- Compared with similar equipment, the overall energy saving of PLA sheet extrusion production line is more than 30-40%.

- Adopt three-stage vacuum exhaust technology and oil-gas separation technology.

- Adopt twin-screw optimized combination technology to ensure product quality and stability.

- Adopt pressure closed-loop feedback control technology, and double PID control technology for heating and cooling temperature field.

- Adopt PLC control to realize parameter setting, data calculation, feedback, and provide improvement measures in real time.

PLA PBS PBAT Starch Straw Sheet Extrusion Line Process flow

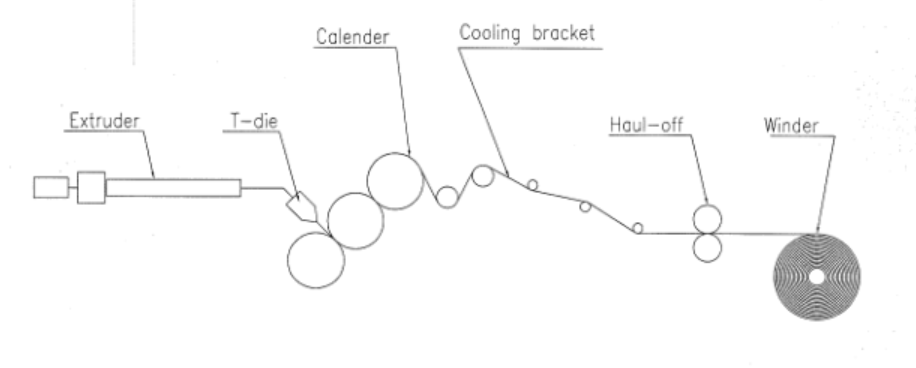

Extruder —- Screen changer —– Melt pump —– T-die —— Calender —– Cooling bracket —– Haul-off—- Winder

Due to environmental pollution and other related problems, like PLA, starch, or straw those kinds of biodegradable raw materials that are used to make sheets for packing are more and more.

PLA polylactic acid starch-based biodegradable material is a new type of bio-based and fully biodegradable material made from starch raw materials proposed by renewable plant resources (such as corn, etc.).

Starch raw materials are saccharified to obtain glucose, then fermented with glucose and certain strains to produce high-purity lactic acid, and then synthesize polylactic acid with a certain molecular weight through chemical synthesis. The utility model has good biodegradability, can be completely degraded by microorganisms in nature under specific conditions after use, and eventually produces carbon dioxide and water, does not pollute soil and air, increases soil fertility, returns to nature, and does not pollute the environment, which is very beneficial for environmental protection and is recognized as an environment-friendly material.

PLA sheet extrusion line

Polylactic acid, also known as polylactide, belongs to the polyester family. Poly (lactic acid) is a polymer obtained from the polymerization of lactic acid as the main raw material, which is usually called corn plastics. It has sufficient sources and can be regenerated.It is a new type of biodegradable polyester material made from l-lactic acid produced by corn and cassava through condensation, cracking, purification, polymerization, and other technological processes.

The pollution-free production process of poly (lactic acid) (PLA), and the product can be biodegradable, implementation cycle in nature, so it is the ideal green polymer material, and it also encourages the development of high-tech environmental protection products. It is widely used in electronic product shells, auto parts, medical equipment, clothing fibers, agricultural plastic films, food packaging, tableware, etc. China GWELL PLA sheet extrusion line is suitable for PLA(PLA) and modified PLA.

PLA is derived from plant resources and can be directly used for extrusion molding. PLA and soluble PLA are widely used in various food packaging and hardware packaging due to their characteristics of biodegradability, composting, and recycling. Rollers can independently drive. As China Plastic Extruder Supplier, GWELL adopts PLC control to realize the automation of actual parameter setting, data operation, feedback, alarm, and other functions.

The PLA sheet extrusion line is a state-of-the-art production system that is engineered to create high-quality PLA sheets with superior properties. The line consists of several components, including a screw extruder, a die head, a three-roll calender, a haul-off unit, and a cutting machine. The extruder is the heart of the system, where the raw PLA material is melted and mixed to form a homogeneous molten mass. The die head is responsible for shaping the molten mass into a flat sheet of the desired thickness and width. The three-roll calender is used to flatten and smooth the sheet, while the haul-off unit and cutting machine are responsible for pulling and cutting the sheet to the desired length.

The PLA sheet extrusion line is a versatile production line that is capable of producing PLA sheets with a wide range of properties, including thickness, width, and texture. The line can be customized to meet specific customer requirements, making it ideal for a variety of applications. The line can produce single-layer or multi-layer sheets, depending on the desired properties. Multi-layer sheets can be used to improve the strength, durability, and barrier properties of the final product. The line is also capable of producing sheets with different surface textures, such as matte or glossy, to suit the specific needs of the application.

The PLA sheet extrusion line offers several advantages over traditional plastic extrusion lines. Firstly, PLA is a renewable resource that is derived from plant sources, making it a more sustainable alternative to traditional petroleum-based plastics. PLA is also biodegradable and compostable, which means that it can be safely disposed of after use. Secondly, the line offers enhanced flexibility in manufacturing, as it can produce sheets with a wide range of properties to suit different applications. This makes it ideal for small-scale and large-scale manufacturing operations alike. Thirdly, the line produces high-quality PLA sheets with superior properties, such as transparency, gloss, and thermal stability, which make them suitable for use in food packaging and medical devices.

In conclusion, the PLA sheet extrusion line is a cutting-edge production system that offers several advantages over traditional plastic extrusion lines. The line is designed to produce high-quality PLA sheets with superior properties, including improved environmental sustainability and enhanced flexibility in manufacturing. The line is ideal for a wide range of applications, including food packaging, medical devices, and consumer goods. With the increasing demand for sustainable and biodegradable materials, the PLA sheet extrusion line is a valuable asset for any manufacturing operation looking to improve their environmental impact and product quality.

Multi-extruder co-extrusion technology can be used to produce multi-layer co-extrusion composite PLA or starch sheet, which is widely used in hot forming, printing, metal packaging, etc.

- equipped with a precision distributor, evenly layered, the adjustable proportion of each layer, digital control accuracy.

- inclined horizontal structure, easy to operate and maintain.

- roller independent power, linear speed, and extruder speed synchronous closed-loop control.

- the whole machine adopts PLC control to realize automatic control of parameter setting, data operation, feedback, alarm, and other functions.

- the electrical control system and operating procedures are independently written by GWELL.

Type of extrusion

PLA sheet single-screw extrusion line (crystallization and drying): PLA single screw extrusion line is similar to PET sheet extrusion line. And China GWELL will use the PLA special extruder, which is suitable for the PLA raw material. The single-screw extrusion line needs crystallization and drying to decrease the moisture. When running the machine, it can avoid crystal points.

China GWELL produced the PLA sheet is better than other companies.PLA sheet twin-crew exhaust extrusion line (free of crystallization and drying): There is little difference with PET Stretch Film Extrusion Line, so the design is different. PLA biodegradable sheet extrusion line that GWELL designed is a PLA special twin-screw free of crystallization and drying machine, which has advantages are lower cost and higher efficiency.

Extrusion type

Single-layer extrusion is made into single-layer PLA sheet, which is a simple and common PLA sheet. GWELL, as China Plastic Extruder manufacturer, will provide specifications according to the raw materials used. Co-extruded into a three-layer PET sheet or multi-layer PLA sheet, such as three-layer sheet, which is composed of PLA+starch+PLA. Because the cost of PLA raw material is much higher than that of PET raw material, some customers require a three-layer sheet extrusion line.

PLA PBS PBAT Starch Straw Sheet Extrusion Line Product Advantages

- Starch–Natural raw materials: China GWELL as extruder manufacturer, uses natural corn starch as raw material, which can be supplied sustainably so that natural resources can be reused and circulated endlessly.

- Degradation – safe biodegradation: the raw materials are natural polymer compounds, which can be degraded in the natural environment.

- Environmental protection–green environmental protection: After the product is used, it can be quickly degraded by microorganisms in the natural environment and become plant nutrients. It truly comes from nature and returns to nature, effectively solving the environmental damage caused by white pollution.

- Health – non-toxic: the raw materials are natural, the production process is sterile, and the disinfection and inspection are strict. After the product is degraded, it will not cause damage to the soil and air, and there is no harm of secondary pollution.

- Low carbon – strong substitution: China GWELL as an extruder manufacturer, its products can replace plastic products with petroleum as raw materials and paper products with wood as raw materials.

Parameter

| Type of extrusion line | single screw PLA sheet extrusion line | PLA sheet parallel twin screw exhaust extrusion line |

| Raw material | PLA or starch | |

| Structure of Product | Single layer, double-layer or three-layer or multi-layer PLA or starch biodegradable sheet | |

| Width of Product | 600mm-1220mm | |

| Thickness of Product | 0.2mm-2mm | |

| Output | 200kg/h-800kg/h | |

| Type of extrusion line | single screw sheet PLA PBS PBAT Starch Straw extrusion line | twin screw venting PLA PBS PBAT Starch Straw sheet extrusion line | ||

| Method of dealing material | Crystallization and drying | Free from crystallization and drying | ||

| Extrusion type | Mono extruded or co-extruded | |||

| Finished Product | Single layer, double-layer or multi-layer PLA 、PBS 、PBAT、starch、straw sheet | |||

| Raw material | PLA PBS PBAT biodegradeble vergin ,starch ,straw | |||

| Net width | 600mm-1220mm and more | |||

| Thickness range | 0.15mm-2mm and more | |||

| Capacity | 200kg/h-1200kg/h and more | |||

| Application | Food and fruit packing ,Printing,Cup, hardware packing and more | |||

Application

PLA sheet is flexible in processing, transparent, non-toxic, environmental friendly and easily to be recycled.

Vacuum Moulding: food packaging,fruit packaging, toy box, gift box, etc.

Obstructing Application: Electronic components packaging

Special Application: medical equipment, medicine packing, industrial antisepsis protection, baking tray for microwave,hardware packing, etc.

Polylactic acid is a new type of polyester material, because its performance is similar to that of existing plastics such as polyethylene, but can be completely degraded by microorganisms in nature, and has excellent biocompatibility. It is an important substitute material for solving the problem of white pollution, and has great potential in the fields of medical health and home textiles such as fast food boxes, express bags, tableware, shopping bags, moisturizing film, insulation boxes, etc.

Client

About Gwell

Innovation drives enterprise progress. Relying on the group’s strong technology, equipment strength and innovation spirit, Gwell is committed to the development of high-tech products and the international market. Gwell also actively exchanges and cooperates with world-class scientific research institutions. The new technologies, new processes and new products developed by Gwell are widely used in building materials(PP hollow sheet extrusion machine, PC optic extrusion machine), home appliances(SPC floor extrusion machine), packaging(PET sheet extrusion machine, EVOH film extrusion machine),

medical treatment(PVC rigid sheet extrusion machine), automobiles(TPU film extrusion machine, PVB film extrusion machine), new energy(EVA solar film extrusion machine), aerospace(TPU film extrusion machine), rail transit(waterproof film extrusion machine) and other fields, which are closely related to human life.

Related Product

The main components of the PC Sheet extrusion production line are selected from the world’s high-quality products (such as screws, barrels, rollers, etc.), and its production process is comprehensive. As an excellent supplier of plastic extruders, GWELL’s complete set of production line has approached the world’s high-quality product standards.

As a premier Chinese manufacturer of plastic extrusion machinery, GWELL delivers cutting-edge PS (Polystyrene) Sheet Extrusion Lines engineered for precision, efficiency, and unmatched product consistency. Our advanced extrusion systems are designed to meet the rigorous demands of diverse industries, offering tailored solutions for high-quality PS sheet production.

As a pioneer in PVB interlayer film production machine technology, we specialize in delivering cutting-edge systems designed for high-performance PVB interlayer film manufacturing. Our PVB interlayer film production machines are engineered to meet global industry standards, combining precision, efficiency, and sustainability.

FAQ

What is the main business of GWELL?

Can I go on a field trip to the GWELL factory?

What are the services for purchasing equipment at GWELL?

What types of plastic extrusion machines are available from GWELL?

What is APET PETG CPET Sheet Extrusion Line?

Where does GWELL ship from?

Are there any technical supports for extrusion machine that you need?

Our service will be always at your disposal over the entire extrusion line life.So if you want to know about any other technical supports.Please contact us as soon as possible.