Products

Gwell’s extrusion technology satisfies customers with the highest economic efficiency

China’s professional plastic extruder suppliers are always exploring new paths for plastic sheet, film, sheet extruders

PRODUCTS CENTER

The main components of the PC Sheet extrusion production line are selected from the world’s high-quality products (such as screws, barrels, rollers, etc.), and its production process is comprehensive. As an excellent supplier of plastic extruders, GWELL’s complete set of production line has approached the world’s high-quality product standards.

As a premier Chinese manufacturer of plastic extrusion machinery, GWELL delivers cutting-edge PS (Polystyrene) Sheet Extrusion Lines engineered for precision, efficiency, and unmatched product consistency. Our advanced extrusion systems are designed to meet the rigorous demands of diverse industries, offering tailored solutions for high-quality PS sheet production.

As a pioneer in PVB interlayer film production machine technology, we specialize in delivering cutting-edge systems designed for high-performance PVB interlayer film manufacturing. Our PVB interlayer film production machines are engineered to meet global industry standards, combining precision, efficiency, and sustainability.

For over a decade, GWELL has pioneered advanced extrusion technologies for solar encapsulation films. Our systems produce high-performance EVA, POE, and innovative EPE films that protect solar cells while maximizing module efficiency.

GWELL as China Plastic Extruder Supplier, Melt-blown fabric mask extrusion line adopts special hanger-type uniform air-jet spinning die head with independent intellectual property rights, and the melt distribution is uniform. The air pressure of the nozzle is stable, the airflow on both sides is symmetrical, and the airflow in the width direction is uniform.

GWELL stone paper extrusion line can produce synthetic paper products with 40% to 80% inorganic powder added. It is composed of raw material conveying and processing system, edge material recovery system, extrusion equipment, casting equipment, longitudinal stretching machine, transverse stretching machine, winding machine, electrical system and automatic film thickness gauge.

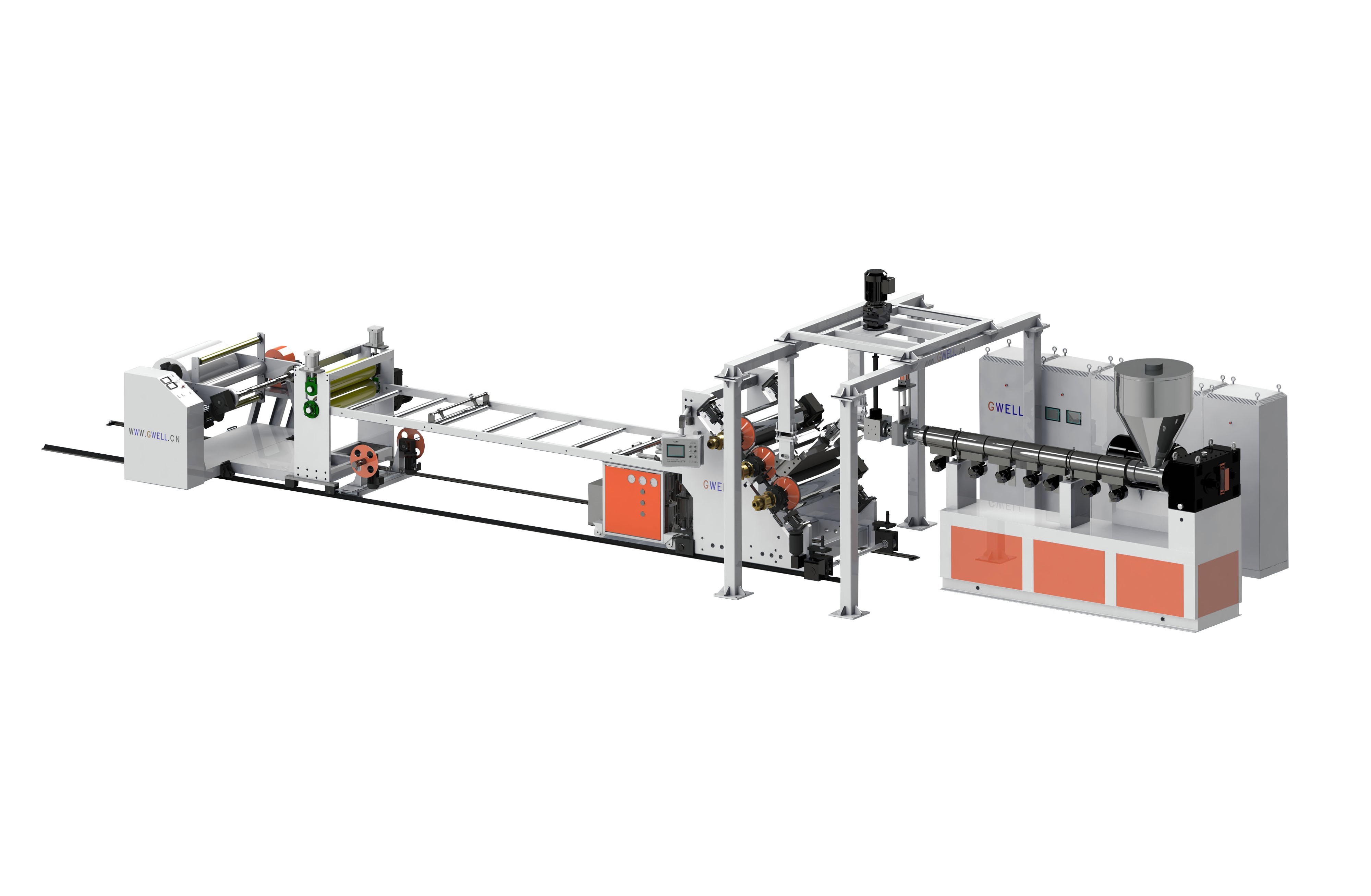

GWELL as China Plastic Extruder manufacturer ,PET stretch film extrusion line adopts single-screw or twin-screw extruder structure to produce cast film of single-layer, double-layer or three-layer co-extrusion structure.

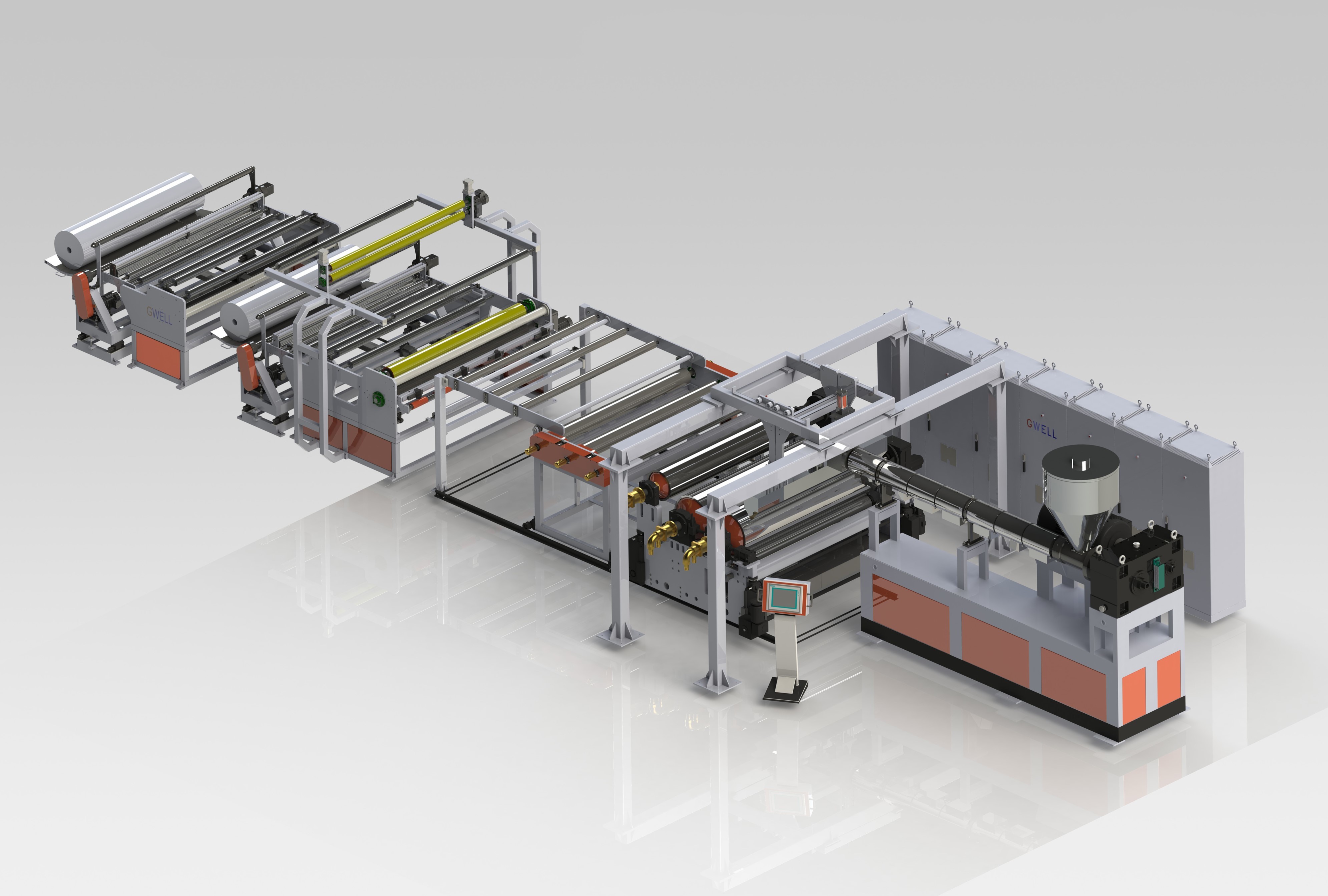

As China Plastic Extruder Supplier, China GWELL PVC Floor Leather Extrusion Line can be equipped with different components for single-layer and multi-layer composite production according to customer requirements. It can also be equipped with an unwinding device for the production of inner reinforced production or surface composite non-woven fabrics, PVC decorative films, etc.

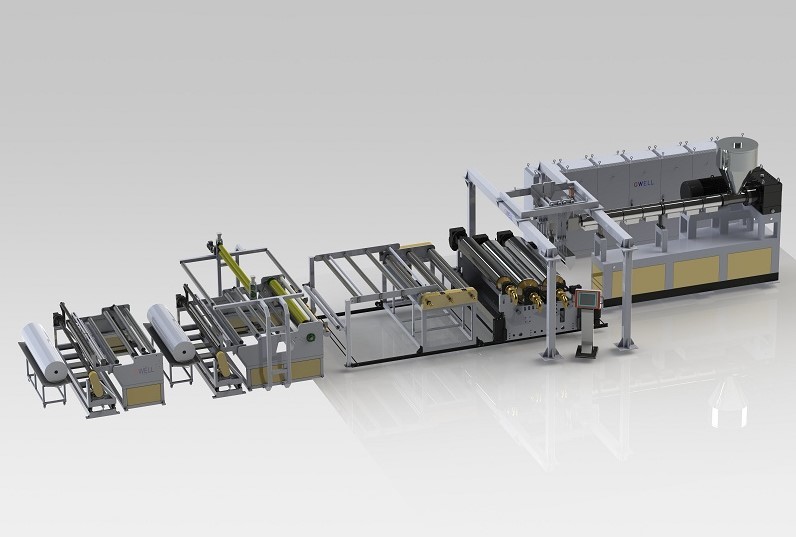

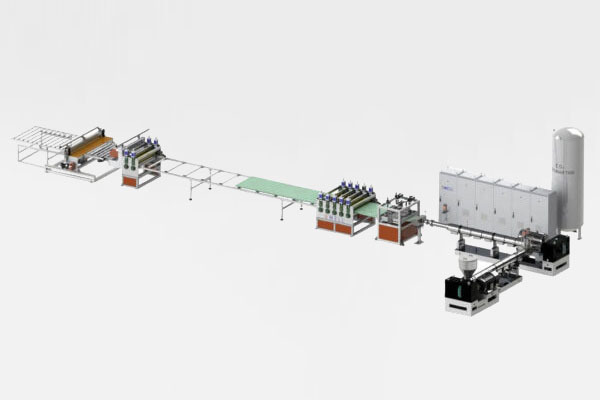

China GWELL, as China Plastic Extruder Supplier, SPC LVT Board Extrusion Line is produced by conical twin-screw extruder, through three or four roll calenders, one-time compounding of PVC color film, PVC wear-resistant layer, and PVC substrate.

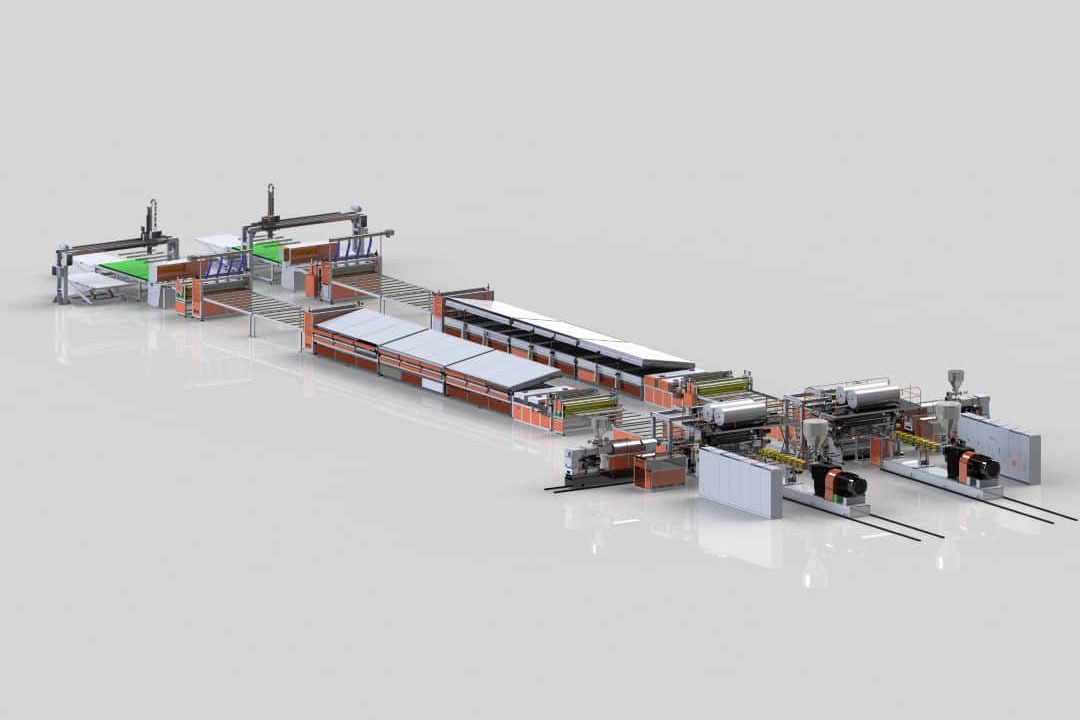

China GWALL, as a Plastic Extruder Supplier, the XPS foaming board extrusion line adopts the component scale to automatically mix and add materials to realize the intelligent injection of CO2 by the flow meter. China GWELL plasticizing adopts two-stage extruder, the first stage adopts co-rotating twin-screw extruder, and the plasticizing and mixing effect is good; the first stage adopts single-screw extruder, which has excellent cooling effect.

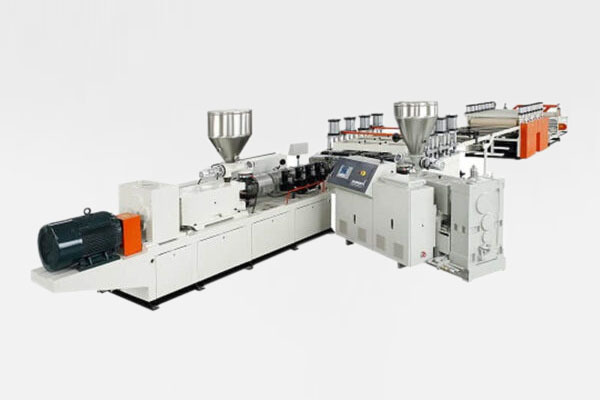

China GWELL as China Plastic Extruder manufacturer, PVC foaming board extrusion line adopts srl-z series hot and cold mixing unit for material mixing. The mixing process of the materials is very important. The quality of the mixture will directly affect the extrusion process and the appearance and internal quality of the sheet.

PVC TPO EVA waterproof sheet extrusion line is simple in structure and easy to operate. China Plastic Extruder manufacturer – GWELL can configure different equipment parts according to customer requirements, and produce single-layer and multi-layer composite products. A winding device can also be installed to produce internal reinforced products or surface composite non-woven products.