PVC TPO EVA Waterproof Sheet Extrusion Line

PVC TPO EVA waterproof sheet extrusion line is simple in structure and easy to operate. China Plastic Extruder manufacturer – GWELL can configure different equipment parts according to customer requirements, and produce single-layer and multi-layer composite products. A winding device can also be installed to produce internal reinforced products or surface composite non-woven products.

Key words:Sheet Extrusion Line

Category:

Waterproof Extrusion Line

Download:

Description

The new type of building waterproof sheet produced by PVC TPO EVA waterproof sheet extrusion line is an important component of building waterproof materials. It is widely used in waterproofing of buildings above ground, underground and special structures.

PVC TPO EVA waterproof sheet extrusion line products

Waterproof board

Polymeric waterproof board, also known as polymer waterproof sheet, is made of synthetic rubber, synthetic resin or a common system of the two as the base material.

Waterproof board features:

- Good aging resistance and long service life;

- Good elasticity and excellent tensile performance;

- Good resistance to high and low temperatures, and can be used in severe cold or hot environments;

- The plate is wide in width and has good weldability;

- Heel penetration resistance, waterproof board on high-speed rail, chemical corrosion resistance;

- Cold construction, PVC TPO EVA waterproof sheet extrusion line has a high degree of mechanization and is easy to operate.

Waterproof panels are suitable for waterproof construction projects that are subject to vibration and easy deformation, and are also suitable for rigid protective layers or inverted roofs, basements, pools, canals, reservoirs, tunnels, subways and other construction projects.

GWELL as China Plastic Extruder Supplier, PVC TPO EVA waterproof sheet extrusion line is a special TPO equipment developed by China Gwell based on customers’ many years of production experience.

The design concept and technical content are of guiding significance to the industry.

The production is stable, with high output, low defect rate, and easy operation. It can meet the production of the homogeneous coil (H type), fiber backing coil (L type), fabric reinforced coil (P type).

PVC TPO EVA waterproof sheet extrusion line is simple in structure and easy to operate. China Plastic Extruder Supplier – GWELL can configure different equipment components according to customer requirements to produce single-layer and multi-layer composite products. A winding device can also be installed to produce internal reinforced products or surface composite non-woven products.

EVA polymer composite self-adhesive waterproof coiled material is a new type of synthetic polymer waterproof coiled material with excellent waterproof performance, which is composed of synthetic polymer EVA composite sheet, high polymer and modified high-quality asphalt.

It has the waterproof performance of both polymer waterproof coiled material and self-adhesive waterproof coiled material. One layer of coiled material and two layers of fortification greatly improve the waterproof effect of the waterproof layer.

China EVA polymer composite waterproof membrane adopts high-quality ethylene vinyl acetate copolymer as the main material, and adds fiber to increase the strength.

Adding modifier to improve the physical and chemical properties of the material.

Adding stabilizer to improve the chemical and physical stability of the product.

Add anti-aging agent to extend the service life of materials.

Adding antioxidants to improve antioxidant performance; Add bactericide to prevent bacterial and mold erosion.

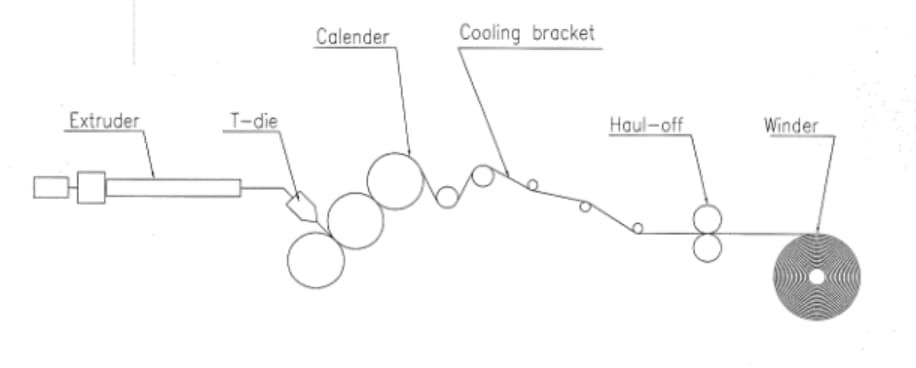

PVC TPO EVA waterproof sheet extrusion line Product Flows

Extruder —- Screen changer —– Melt pump —– T-die —— Calender —– Thickness Scanner —-Cooling Bracket —-Cutting Knife —- Haul-off —-Winder

Parameter

| Extruder Type | Single screw extruder GWS120/ Parallel twin screw extruder GWP75 | Single screw extruder GWS130/ Parallel twin screw extruder GWP85 | Single screw extruder GWS150/ Parallel twin screw extruder GWP95 | GWP75/ GWP75 | GWS130+GWS130 | GWP95-GWP95 |

| Raw material | EVA | TPO+NET+TPO | ||||

| Net width | 2000mm | 4000mm | 6000mm | 2100mm | 2100mm | 2100mm |

| Thickness range | 0.8-3mm | 1-3mm | ||||

| Capacity | 650kg/h | 850kg/h | 1200kg/h | 800kg/h | 1000kg/h | 1200kg/h |

Application

China Plastic Extruder Supplier PVC TPO EVA waterproof sheet extrusion line is a new type of waterproof sheet with thermoplastic polyolefin as raw material, adding antioxidant, anti-aging agent, softener, etc., with polyurethane mesh reinforcement layer in the middle and fabric fiber and aluminum film on the surface material.

TPO waterproof coil has excellent weather resistance and flexibility. Mainly used for all kinds of roofing, basement, tunnel and other building waterproof engineering.

EVA waterproof and anti-seepage works such as tunnels, subways, highways, tunnels and bridges;

Waterproof and anti-seepage of roof, basement, etc. Waterproof and anti-seepage works such as reservoir dams, cofferdams and canals.

Anti-seepage and waterproof works such as waste landfill, sewage treatment plant, metallurgy and chemical plant.

Other works requiring waterproof, anti-seepage and moisture-proof treatment.

Client

About Gwell

Innovation drives enterprise progress. Relying on the group’s strong technology, equipment strength and innovation spirit, Gwell is committed to the development of high-tech products and the international market. Gwell also actively exchanges and cooperates with world-class scientific research institutions. The new technologies, new processes and new products developed by Gwell are widely used in building materials(PP hollow sheet extrusion machine, PC optic extrusion machine), home appliances(SPC floor extrusion machine), packaging(PET sheet extrusion machine, EVOH film extrusion machine),

medical treatment(PVC rigid sheet extrusion machine), automobiles(TPU film extrusion machine, PVB film extrusion machine), new energy(EVA solar film extrusion machine), aerospace(TPU film extrusion machine), rail transit(waterproof film extrusion machine) and other fields, which are closely related to human life.

Related Product

The main components of the PC Sheet extrusion production line are selected from the world’s high-quality products (such as screws, barrels, rollers, etc.), and its production process is comprehensive. As an excellent supplier of plastic extruders, GWELL’s complete set of production line has approached the world’s high-quality product standards.

As a premier Chinese manufacturer of plastic extrusion machinery, GWELL delivers cutting-edge PS (Polystyrene) Sheet Extrusion Lines engineered for precision, efficiency, and unmatched product consistency. Our advanced extrusion systems are designed to meet the rigorous demands of diverse industries, offering tailored solutions for high-quality PS sheet production.

As a pioneer in PVB interlayer film production machine technology, we specialize in delivering cutting-edge systems designed for high-performance PVB interlayer film manufacturing. Our PVB interlayer film production machines are engineered to meet global industry standards, combining precision, efficiency, and sustainability.

FAQ

What is the main business of GWELL?

Can I go on a field trip to the GWELL factory?

What are the services for purchasing equipment at GWELL?

What types of plastic extrusion machines are available from GWELL?

What is APET PETG CPET Sheet Extrusion Line?

Where does GWELL ship from?

Are there any technical supports for extrusion machine that you need?

Our service will be always at your disposal over the entire extrusion line life.So if you want to know about any other technical supports.Please contact us as soon as possible.

Previous