PVA Film Extrusion Line

China Plastic Extruder Supplier – GWELL product PVA film extrusion line adopts blown film production process to continuously produce thermoplastic polyvinyl alcohol (PVA) water-soluble film. It has the characteristics of stable product performance and high production efficiency.

Key words:Sheet Extrusion Line

Category:

Film Extrusion Line

Download:

Description

China Plastic Extruder Supplier – GWELL product PVA film extrusion line adopts blown film production process to continuously produce thermoplastic polyvinyl alcohol (PVA) water-soluble film. It has the characteristics of stable product performance and high production efficiency.

PVA film extrusion line

- PVA film extrusion line products are water-soluble and soluble in cold water. The water-soluble speed can be designed and selected, and it is non-toxic and non-polluting.

- Anti-static property, China GWELL water-soluble film is an anti-static film. Different from other plastic films, it has good anti-static property. In the process of packaging products with water-soluble film, the plasticity and static electricity will not be reduced due to static electricity. Dust attachment performance.

- Moisture and gas permeability. The water-soluble film has strong permeability to moisture and ammonia, but has good barrier properties to oxygen, nitrogen, hydrogen and carbon dioxide. These characteristics make it possible to keep the ingredients and original smell of the packaged products intact.

- Heat sealability The water-soluble packaging film has good heat sealability and is suitable for resistance heat sealing and high frequency heat sealing.

- Mechanical properties. Mechanical properties of water-soluble packaging film: strength modulus 2500-400kg/cm2, tearing force 200-50kg/cm2, elongation 150-220%.

- Oil resistance and chemical resistance Water-soluble packaging film has good oil resistance (vegetable oil, animal oil, mineral oil), fat, organic solvent and carbohydrates, etc.

PVA film extrusion line features:

- GWELL as China Plastic Extruder manufacturer, the screw is designed with a special mixing function and high plasticizing capacity.

- The hanger-type die adopts a special double-throttle design, which makes the thickness adjustment of the plate more accurate.

- Temperature control ± 1C can precisely control the plasticization process and the thickness and smoothness of the product.

- Three-roll calendar adopts horizontal, vertical, or 45-degree inclination type, which can be raised and lowered freely.

- The thickness of the sheet is controlled by screw adjustment and bidirectional adjustment of the pressure wheel to control the thickness of the sheet.

Features of China GWELL PVA film extrusion line:

- Smooth surface, no cracks, no bubbles, uniform color, heat resistance, cold resistance, aging resistance, heavy pressure resistance, strong acid and alkali resistance, good light transmission, and long service life. To a certain extent, it can be used as a substitute for glass, but its excellence is unmatched by glass. In particular, the impact resistance and tensile strength of soft glass not only ensure its long service life, but more importantly, it will not cause harm to the human body. It is warm in winter and cool in summer and soft in quality, making desktop office workers particularly comfortable work.

- Anti-light, not deformed, not broken, not hard, high elasticity.

- Soft texture, easy to write.

- China GWELL PVA film extrusion line products are heat-resistant to 100℃, resistant to -30℃, strong acid and alkali resistance, and heavy pressure resistance, which can help dry and improve the efficiency of surface work, reduce cleaning costs for dry restaurants, and add elegance to the restaurant.

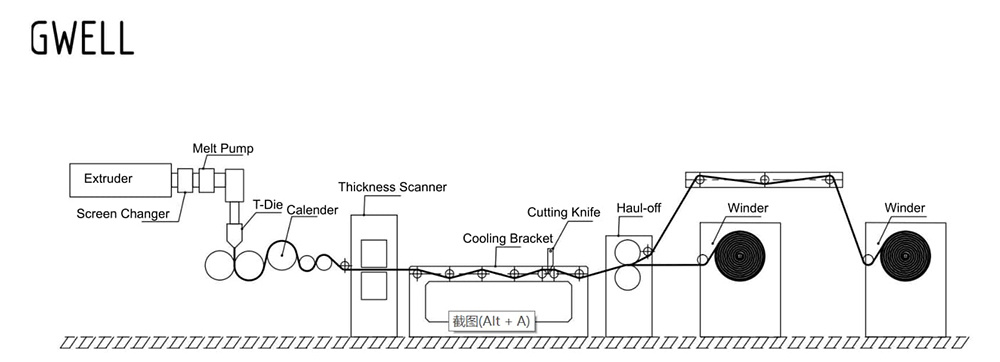

PVA film extrusion line Product Flows

Extruder —- Screen changer —– Melt pump —– T-die —— Calender —– Thickness Scanner —-Cooling Bracket —-Cutting Knife —- Haul-off —-Winder

Polyvinyl alcohol (PVA) is a water-soluble polymer, which is characterized by good compactness, high crystallinity, strong adhesion, flexible and smooth film, oil resistance, solvent resistance, wear resistance, good gas permeability, and water resistance after special treatment. It is widely used.

Polyvinyl alcohol is non-toxic, tasteless, and harmless to the human body. It has a good affinity with the natural environment, with no accumulation, and no pollution.

Polyvinyl alcohol film is a green environmental protection functional material with polyvinyl alcohol as the main body, modifier, and other additives, which can be completely degraded by microorganisms in the soil after special processing. It can be degraded into carbon dioxide and water in a short time and can improve the land.

The biggest advantage of the polyvinyl alcohol film produced by China Plastic Extruder manufacturer is water solubility, and the biggest disadvantage is poor water resistance. The poor water resistance is due to the hydrophilic hydroxyl group (-OH) in its molecule. If the water resistance of the PVA film can be properly blocked and linked with water-resistant groups, the water resistance of the PVA film can be improved.

PVA contains hydroxyl groups, which can produce all typical reactions of polyols. With appropriate polycondensation, it can properly interact with the hydroxyl groups in PVA when the addition amount is small, so as to form a strong and tough three-dimensional structure of PVA, stabilize the airtightness of PVA under wet conditions and improve the water resistance.

Parameter

| Extruder Type | GWS90 |

| Raw material | PVA |

| Net width | 1000mm |

| Thickness range | 0.03-0.07mm |

| Capacity | 150-180kg/h |

Application

Fast dissolving film

- The inner packaging of pesticides and chemical products is lined with bags, which can avoid touching pesticides and chemical products by hand, and there is no residual pesticide in the plastic bag.

- cement additive packaging bag to avoid dust flying and harming the environment.

- embroidery substrate, wig and other fabric carriers. Set off the carrier for easy cleaning.

- artificial marble demoulding film, which is padded with water-soluble film, can demould quickly.

- water transfer printing, which can be transferred to the curved surface after printing on the film.

- seed bag: pack the seeds at fixed intervals and then bury them underground to save valuable seeds and save the busy of inter seedling.

- the hospital washes the packaging bag without contacting contaminated clothes, and the packaging bag is directly put into the washing machine.

- garbage bag.

Medium soluble film

- food and cosmetics packaging bags, supermarket shopping bags.

- food packaging composite film, high-grade textiles, plastic bag packaging bag, packaging cushion air cushion.

- beautiful printing effect can be obtained by using glass paper printing ink.

- packaging of animal oil, vegetable oil and mineral oil and packaging of fat food.

- used for packaging and sealing of tea, coffee, curry powder, chili powder, pepper powder and other spices.

- it can be used for the packaging of small Cereals, oil, seafood, dry hair, precious traditional Chinese medicine, tobacco, etc. it can be used in combination with deoxidizer or vacuum pumping to ensure its quality and freshness against mildew, moth and fading.

- anti static packaging of electronic products.

Insoluble film

- The sealing of clothing, shoes and hats, leather and leather products, arts and crafts, manuscripts and archives can be used together with a deoxidizer to prevent mildew, moth, and oxidation discoloration.

- beautiful printing effect can be obtained by using glass paper printing ink.

- packaging of alcohols, ethers, ketones, esters, chemical raw materials and intermediates.

- packaging of daily necessities, medicine and toys.

- it is used for the storage of radio components and complete machines, precision machinery, ordnance, radar and ammunition, with unique anti-oxidation and corrosion function.

- optical instruments, lenses and spare parts are sealed comprehensively to prevent mildew and fog.

Special film

The polyvinyl alcohol film produced by China Plastic Extruder manufacturer can also be used in special fields such as polarization mode, automotive film, windshield interlayer, and sanitary material manufacturing.

Client

About Gwell

Innovation drives enterprise progress. Relying on the group’s strong technology, equipment strength and innovation spirit, Gwell is committed to the development of high-tech products and the international market. Gwell also actively exchanges and cooperates with world-class scientific research institutions. The new technologies, new processes and new products developed by Gwell are widely used in building materials(PP hollow sheet extrusion machine, PC optic extrusion machine), home appliances(SPC floor extrusion machine), packaging(PET sheet extrusion machine, EVOH film extrusion machine),

medical treatment(PVC rigid sheet extrusion machine), automobiles(TPU film extrusion machine, PVB film extrusion machine), new energy(EVA solar film extrusion machine), aerospace(TPU film extrusion machine), rail transit(waterproof film extrusion machine) and other fields, which are closely related to human life.

Related Product

The main components of the PC Sheet extrusion production line are selected from the world’s high-quality products (such as screws, barrels, rollers, etc.), and its production process is comprehensive. As an excellent supplier of plastic extruders, GWELL’s complete set of production line has approached the world’s high-quality product standards.

As a premier Chinese manufacturer of plastic extrusion machinery, GWELL delivers cutting-edge PS (Polystyrene) Sheet Extrusion Lines engineered for precision, efficiency, and unmatched product consistency. Our advanced extrusion systems are designed to meet the rigorous demands of diverse industries, offering tailored solutions for high-quality PS sheet production.

As a pioneer in PVB interlayer film production machine technology, we specialize in delivering cutting-edge systems designed for high-performance PVB interlayer film manufacturing. Our PVB interlayer film production machines are engineered to meet global industry standards, combining precision, efficiency, and sustainability.

FAQ

What is the main business of GWELL?

Can I go on a field trip to the GWELL factory?

What are the services for purchasing equipment at GWELL?

What types of plastic extrusion machines are available from GWELL?

What is APET PETG CPET Sheet Extrusion Line?

Where does GWELL ship from?

Are there any technical supports for extrusion machine that you need?

Our service will be always at your disposal over the entire extrusion line life.So if you want to know about any other technical supports.Please contact us as soon as possible.

Previous

下一页