BIPV PVB Photovoltaic Film Production Line

The PVB photovoltaic film production line manufactured by GWELL incorporates a one-of-a-kind design and cutting-edge manufacturing technology to enhance machine stability and automation.

Key words:Sheet Extrusion Line

Category:

Solar Extrusion Line

Download:

Description

Introduction of BIPV PVB photovoltaic film production line

GWELL manufactures the PVB photovoltaic film production line. China's top three PVB producers all utilize GWELL's dry (roller method) and wet (water method) PVB film extrusion machine. India's inaugural PVB film production line was also built by GWELL.

Production Specifications:Maximum film width: 3600mm

Thickness range: 0.38-1.52mm

Output capacity: 500-800kg/h

Shrinkage rate: ≤2%

Total line length: 28m

Customizable width cutting

Key Characteristics:

Compatibility with diverse material systems

Fully integrated automation from feeding to winding

PLC-controlled turnkey solutions

High-output/low-energy-consumption operation

Advanced automation technology

BIPV PVB photovoltaic film production line is divided into two methods

- The dry process, also known as the silver process, is cast and extruded, cooled in the air, shaped, and rolled.

- The wet process, also known as the water-passing process, the tape-extruded film is cooled and shaped by a water tank, and then dried and wound.

There is a big difference in production line between the two processes, and the price is also very different. The main machine can also use a single-screw extruder or parallel twin-screw extruder according to different needs and raw material conditions.

The main purpose of BIPV PVB photovoltaic film production line

- PVB automotive safety glass film production line: PVB film is mainly used for the middle layer of the front windshield of the car.

- PVB architectural glass interlayer film production line: PVB film is mainly used for the interlayer of high-rise building glass.

- PVB solar film production line: PVB film is used for the packaging of photovoltaic solar thin-film cells.

BIPV photovoltaic grade PVB film production line

- PVB has the advantages of strong adhesion, impact resistance, UV isolation, sound insulation, and environmental protection. It is currently mainly used in building and automotive safety glass.

- PVB is expected to gradually penetrate into the field of photovoltaic packaging film, and the application of the BIPV field may be the first to break through.

- PVB interlayer film is mainly used as a packaging material in the double-glass field (one side of the traditional single-sided module is the frame, and PVB packaging is mainly a double-sided lamination process). Currently, PVB has high production barriers and high packaging costs due to photovoltaic products. The proportion of high-level problems is still small, but with its good performance such as high adhesion, high water penetration resistance, and high weather resistance, it is expected to gradually attract attention with the increase in the application of double-sided modules.

Advantages of PVB encapsulation film

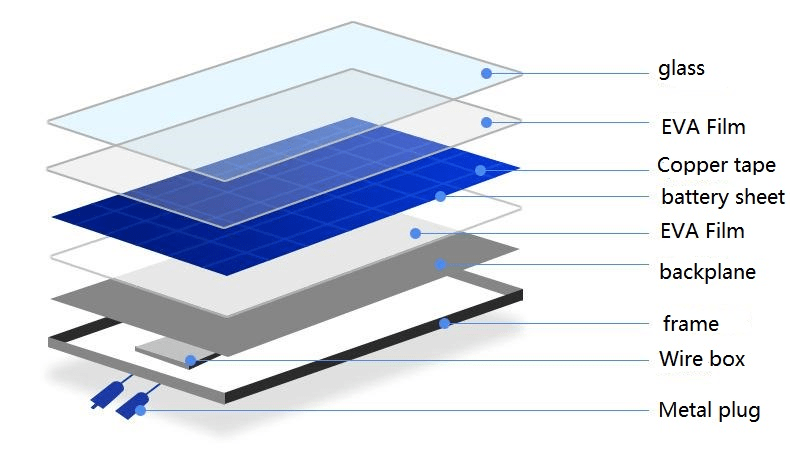

- PVB film is mainly used for BIPV modules, the structure is steel glass (ultra-clear)-PVB_cell-PVB-tempered glass (ordinary).

- Comparison of PVB packaging film and EVA packaging film EVA is a thermosetting resin with cross-linking reaction, while PVB is a thermoplastic resin with reproducibility and no cross-linking reaction.

- The domestic glass curtain wall specification clearly puts forward the requirement of “application of PVB”. BIPV photovoltaic modules are made of PVB instead of EVA to achieve a longer service life.

- PVB has strong adhesive performance, and its safety is higher than that of EVA film.

- EVA POE Solar Film Extrusion Line has many formulas, and the packaging process is not easy to control; the formula of PVB film is simple, the quality control is stable, and the shelf life is long.

- The fluidity of PVB film is poor, which can prevent the overflow of the film during processing.

The PVB photovoltaic film production line manufactured by GWELL incorporates a one-of-a-kind design and cutting-edge manufacturing technology to enhance machine stability and automation. The feeding system is seamlessly integrated with the extruder, enabling precise online proportioning of raw materials, resulting in consistent PVB film quality and decreased labor requirements. Specially designed rollers are utilized for even cooling of the PVB film, mitigating stress induced by uneven heating and cooling, and guaranteeing the accurate shrinkage rate. This innovative approach not only improves efficiency and product consistency, but also ensures high-quality output for the photovoltaic film industry.

The PVB (polyvinyl butyral) film used in the production of BIPV PVB photovoltaic film is a thermoplastic resin film made from PVB resin and plasticizer. It is commonly utilized in various applications such as architectural laminated glass, automotive laminated glass, solar photovoltaic glass, bulletproof glass, and soundproof glass. This film provides excellent safety features by preventing glass breakage from external forces and reducing the risk of glass shards causing harm to individuals. Additionally, it offers sound insulation and UV protection, and can be customized to be either colorful or highly transparent. For over seven decades, this film has been a staple in building curtain wall glass, showcasing its optical application value and potential for solar photovoltaic integration. PVB film is currently produced by roller forming and water forming and can produce transparent color strips and full-color films with a thickness of 0.38-1.52mm and a width of 500-3400mm.

Parameter

| Extruder Type | Single screw extruder GWS150,GWS160,GWS180 | Co-extrusion GWS160+GWS160,GWS180+GWS160,GWS180+GWS180 |

| Raw material | EVA, POE | EVA, POE |

| Layers | EVA or POE single layer | EVA or POE single layer,EVA/POE/EVA three layers |

| Net width | 2000mm,2400mm,2600mm | |

| Thickness range | 0.2mm-1mm | |

| Max linear speed | 10m/min,12m/min,16m/min,18m/min | |

| Application | EVA/POE film for solar encapsulation | |

Application

Client

About Gwell

Innovation drives enterprise progress. Relying on the group’s strong technology, equipment strength and innovation spirit, Gwell is committed to the development of high-tech products and the international market. Gwell also actively exchanges and cooperates with world-class scientific research institutions. The new technologies, new processes and new products developed by Gwell are widely used in building materials(PP hollow sheet extrusion machine, PC optic extrusion machine), home appliances(SPC floor extrusion machine), packaging(PET sheet extrusion machine, EVOH film extrusion machine),

medical treatment(PVC rigid sheet extrusion machine), automobiles(TPU film extrusion machine, PVB film extrusion machine), new energy(EVA solar film extrusion machine), aerospace(TPU film extrusion machine), rail transit(waterproof film extrusion machine) and other fields, which are closely related to human life.

Related Product

The main components of the PC Sheet extrusion production line are selected from the world’s high-quality products (such as screws, barrels, rollers, etc.), and its production process is comprehensive. As an excellent supplier of plastic extruders, GWELL’s complete set of production line has approached the world’s high-quality product standards.

As a premier Chinese manufacturer of plastic extrusion machinery, GWELL delivers cutting-edge PS (Polystyrene) Sheet Extrusion Lines engineered for precision, efficiency, and unmatched product consistency. Our advanced extrusion systems are designed to meet the rigorous demands of diverse industries, offering tailored solutions for high-quality PS sheet production.

As a pioneer in PVB interlayer film production machine technology, we specialize in delivering cutting-edge systems designed for high-performance PVB interlayer film manufacturing. Our PVB interlayer film production machines are engineered to meet global industry standards, combining precision, efficiency, and sustainability.

FAQ

What is the main business of GWELL?

Can I go on a field trip to the GWELL factory?

What are the services for purchasing equipment at GWELL?

What types of plastic extrusion machines are available from GWELL?

What is APET PETG CPET Sheet Extrusion Line?

Where does GWELL ship from?

Are there any technical supports for extrusion machine that you need?

Our service will be always at your disposal over the entire extrusion line life.So if you want to know about any other technical supports.Please contact us as soon as possible.