PP Hollow Board Extrusion Line

GWELL, as China Plastic Extruder Supplier, PP Hollow Board Extrusion Line adopts PP hollow special single-screw extruder and double extruder for co-extrusion. Because PP hollow board is divided into white and black PP hollow board. Sometimes the middle of the board will be white. So China GWELL will use two extruders.

Key words:Sheet Extrusion Line

Category:

Hollow Extrusion Line

Download:

Description

PP Hollow Board Extrusion Line Description

China GWELL, a prominent manufacturer of extruders, offers an advanced PP Hollow Board Extrusion Line for solar panels, crafted from high-performance engineering plastic—polycarbonate resin. This material boasts remarkable transparency, lightweight properties, exceptional impact resistance, sound insulation, and thermal insulation. It represents a cutting-edge solution with outstanding overall performance, designed to be energy-efficient and environmentally friendly. Renowned for its heat resistance, flame retardancy, and anti-aging qualities, polycarbonate is a widely used plastic building material in international markets. Its applications span various sectors, including lighting ceilings and sunshade canopies in commercial spaces, factories, and stadiums, as well as in agricultural greenhouses, aquaculture facilities, and floral greenhouses. Additionally, it serves vital roles in public infrastructure, such as telephone booths, newsstands, transportation stations, highway sound barriers, and advertising displays.

Among the diverse range of packaging boxes made from various materials, the PP hollow board extrusion line stands out as a highly popular option. Its aesthetic appeal and functional advantages have garnered widespread satisfaction among users. This high-quality hollow board packaging box, often referred to as the PP plastic turnover box, is crafted from environmentally friendly raw materials, specifically polypropylene (PP). It is free from any unpleasant odors and boasts an impressive lifespan. Additionally, it exhibits remarkable properties such as corrosion resistance, wear resistance, compression strength, vibration dampening, UV protection, thermal insulation, and soundproofing capabilities.

China GWELL is not only a professional manufacturer, but also a professional supplier of plastic extruder and plastic molding machine. The main product is plastic extruder or plastic molding machine, our advantage is that we can provide you raw material for PP hollow board at competitive price without any extra cost.

The PP hollow board extrusion line produces hollow boards primarily from polypropylene (PP) and high-density polyethylene (HDPE) resin, along with various additives. Additionally, there is the polycarbonate (PC) hollow board, commonly referred to as sunshine board. This type of board, made from engineering-grade PC resin, boasts impressive features such as high transparency, lightweight construction, impact resistance, sound insulation, and thermal insulation.

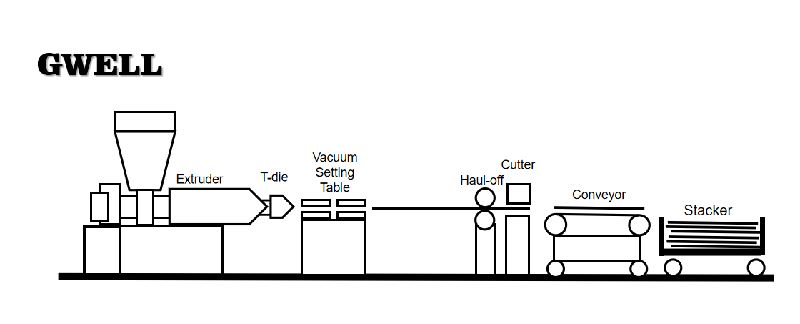

PP Hollow Board Extrusion Line Process Flows

Extruder —- Screen changer —– Melt pump —– T-die —— Vacuum Setting Table—– Haul-off —-Cutter —-Conveyor —- Stacker

Features of PP Hollow Board Extrusion Line

- The unique design of the mold, setting plate, cooling system and vacuum system ensures high-speed extrusion molding, good wear resistance, good shapeability, and easier operation.

- Through the design of the two-stage combined tractor, the flatness of the product can be effectively controlled, and the unqualified products produced by each startup can be reduced.

- The special cutting design can reduce the burrs on the end face of the product to a certain extent. For the improved sawtooth of PP raw materials, the sawdust will not stick during cutting. The automatic fixed-length function of the product is convenient for personnel to operate and has high cutting accuracy.

- China GWELL as a supplier of extruders The whole line adopts new process technology, the production line speed is fast, and the extruder adopts energy-saving and high-efficiency extruder, which has high extrusion volume, good plasticization and stable conveying.

Hollow board features

- Light weight, anti-stretch and other properties.

- The surface can be printed or pasted with lamination.

- Different colors can be produced according to demand.

- By adding flame retardant, the produced hollow board can be extinguished immediately after fire.

- PP hollow board extrusion line has high efficiency.

- Production flexibility (the thickness and width of the plate can be controlled, for example, the same mold or machine can be used to produce 2-6mm thick plates)

- PP hollow board extrusion line reliability and stability.

- Strong adaptability to different raw materials, and the production cost is reduced by more than 30%.

- Diversity of finished product size and shape.

GWELL PP hollow board extrusion line Feature

1. Extruder

As a manufacturer of plastic extruders in China, Gwell employs a specialized single-screw extruder designed for producing PP hollow materials, in addition to utilizing a twin-screw extruder for co-extrusion processes. The production lines for PP hollow boards are categorized into white and black variants, and occasionally, the white material may manifest in the center of the board. To address this, Gwell incorporates the use of two extruders in their operations.

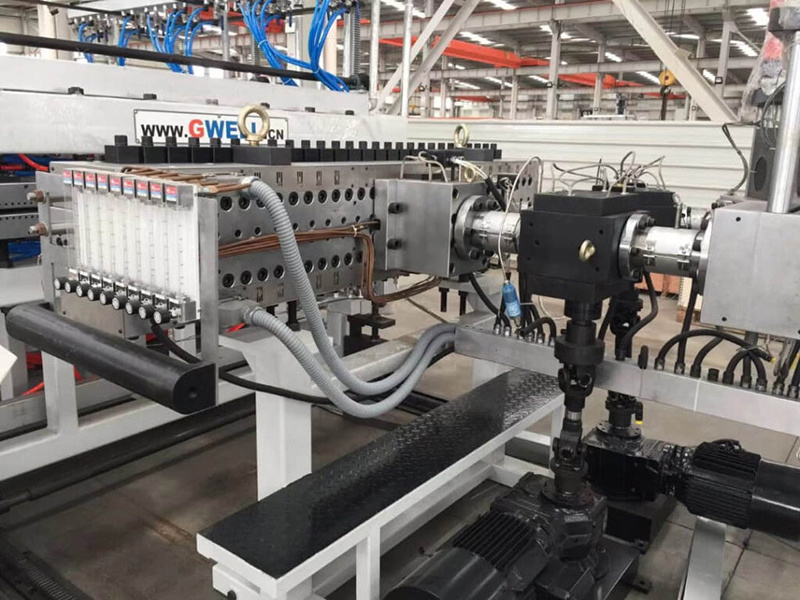

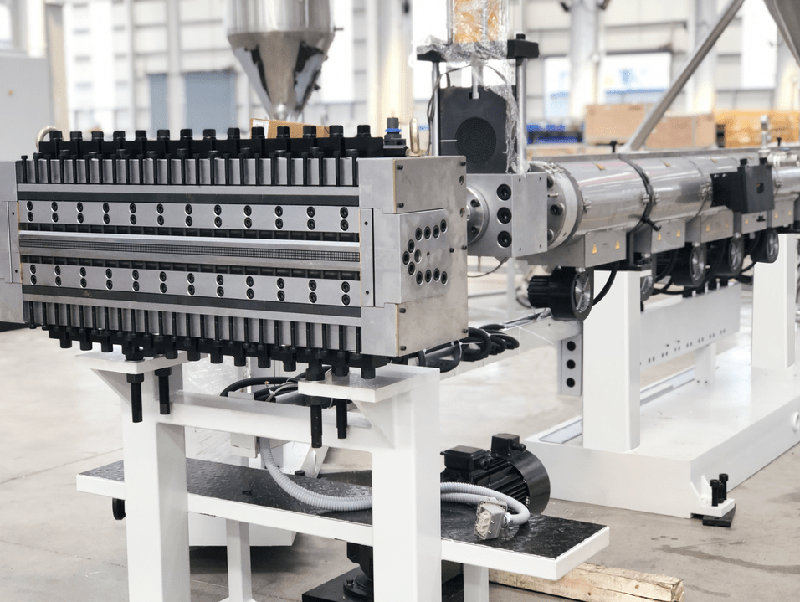

2. T-die

The design of the template has evolved from its original O-shaped hollow configuration to various forms, including M-shaped, V-shaped, and N-shaped structures, ultimately stabilizing in a well-shaped design. Consequently, Gwell advises customers to opt for a well-shaped T-die.

3. Vacuum Setting Table

China Gwell is dedicated to the development of setting units. The Vacuum Setting Table not only provides efficient cooling capabilities but also enhances the forming process significantly.

4. Cooling part

"Utilize Gwell's innovative cooling rollers and stress-relieving cooling beds to ensure that the board operates seamlessly and achieves its optimal shape."

5. Automatic operation

"The entire system utilizes PLC automatic control to facilitate seamless interaction between the operator and the machine interface, ensuring that operations are both user-friendly and automated."

6. PP hollow board extrusion line screen changer

A hydraulic quick screen changer is designed to facilitate a rapid and efficient screen-changing process. Featuring a dual-station setup and a specialized sealing mechanism, it ensures the stable operation of the screen changer. Additionally, this equipment is utilized in the production line for PP hollow packaging boards, specifically catering to manufacturers of hollow lattice board products.

7. Tractor

The advanced PP hollow board extrusion line features two sets of tractors. The primary tractor boasts high power and a substantial reduction ratio, employing a multi-roller design that ensures excellent low-speed performance and significant tractive force. This allows it to uniformly extract the board from the vacuum setting table simultaneously. The secondary tractor is specifically designed to relieve any stress in the product. Furthermore, the line is equipped with edge trimming machinery to ensure both the effective width and the quality of the board's edges are maintained.

8. Stress relief equipment

The advanced PP PC PE Hollow Sheet Extrusion Line employs a large-area conduction heating mode, which significantly alleviates board stress and enhances the overall flatness of the sheets.

9. Electric control of the whole line

"Advanced technology enables the comprehensive control of all parameters across the entire production line through the utilization of a microcomputer (PLC). This capability effectively enhances the operational characteristics of the entire production process. GWELL proudly stands as a leading supplier of plastic extruders in China."

10. Extrusion die

The high-quality alloy used in the extrusion die lip and choke rod ensures a steady pressure drop from the die inlet to the die lip. Furthermore, meticulously engineered molds are instrumental in producing extruded sheets of exceptional quality.

11. Vacuum calibration table

The thermal convection system of the calibration bench is designed with a cross arrangement, which guarantees the effective cooling of the hot PC resin stream. This configuration ensures that the final extrudate attains the desired shape and precise dimensions. Regarding the forming process, our multi-layer sheet extrusion machines facilitate rapid formation by utilizing setting and cooling methods that do not require cold water. This approach not only conserves energy but also enhances overall efficiency.

12. Dry Vacuum Calibrator

The vacuum calibrator comprises two distinct subsystems, each featuring multiple closed-loop vacuum channels.

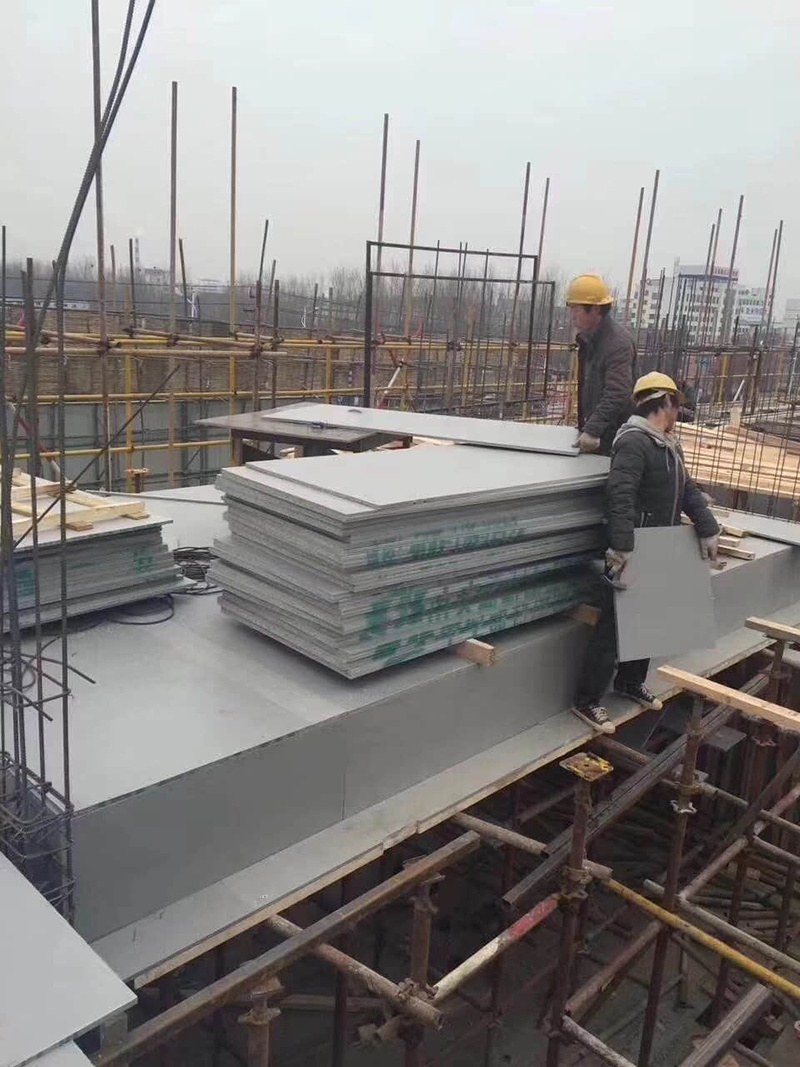

Advantages of the PP hollow board

- Good water resistance. Even if it is completely immersed in water for several days, it will not be deformed by moisture. Acid and alkali resistance, corrosion resistance, no decay, no rust, especially suitable for basement projects, highway and railway bridge piers, and other humid environments.

- "Cement does not easily adhere to surfaces. Once the formwork is in place, it can be easily removed without the risk of deformation caused by cement sticking."

- The surface of the plastic template is smooth, and there is no need to brush the release agent, which reduces the cost of cleaning and maintenance. The surface of the construction building is smooth and flat, and no secondary modification is required.

- Lightweight, high efficiency, easy to open and dismantle the mold, low labor intensity of the handling operation, and high construction efficiency.

- High support strength, not easy to deform, impact resistance and wear resistance.

- Low cost. The service life is long, and the number of cycles used can reach more than 100 times. In addition, the used waste boards and leftover materials can be recycled and reused, saving costs and reducing pollution. The comprehensive use cost can be saved by more than 30% compared with traditional wooden formwork.

- "With a long lifespan and the ability to endure repeated use, the ultimately worn-out plastic template can still be crushed and reprocessed into a new template. This process not only conserves resources but also aligns with the principles of a 'green industry'."

- "Effective thermal insulation plays a crucial role in reducing the construction timeline."

- The method of combining with wood can be used for various treatments, and welding can also be carried out, so secondary processing can be carried out flexibly on the construction site.

PP hollow board extrusion line PP main components

- Single screw extruder

- Hydraulic quick change filter

- Mould

- Calibration table

- The first traction device

- Oven

- Cooling Station

- Second traction unit

- Cutting unit

- Automatic control cabinet

- Stack table

- Screw Loader

One of the key features of the PP hollow board extrusion line is its efficiency. It is equipped with an advanced production system that ensures fast and seamless production, enhancing productivity and reducing production time. Additionally, the machine is designed to minimize waste, which translates into lower production costs and increased profitability for clients.

it is also designed with versatility in mind. It can handle a wide range of materials, including PP, making it an ideal option for clients looking to produce a variety of products. The machine is also built to cater to various production capacities, with options ranging from small-scale to large-scale production.

Another significant advantage of the PP hollow board extrusion line is its exceptional quality. It produces PP hollow boards that meet international standards for impact resistance, heat insulation, and other critical parameters. This makes it an ideal option for clients looking to produce high-quality boards that offer superior protection against external factors.

The PP hollow board extrusion line is also designed with user-friendliness in mind. It comes equipped with an intuitive control system that makes it easy to operate, even for those with minimal technical expertise. The machine is also designed to be low maintenance, with minimal requirements for upkeep, which further reduces costs for clients.

Beyond its remarkable performance and dependability, the PP hollow board extrusion line is thoughtfully engineered with safety as a priority. It is outfitted with a range of safety features, such as an emergency stop button, an automatic shutdown function, and an overload protection system. These elements work together to mitigate the risk of accidents and safeguard the well-being of operators.

The PP hollow board extrusion line stands out for its environmentally friendly design, making it an excellent choice for clients aiming to lower their carbon footprint. This innovative system consumes significantly less energy compared to conventional extrusion lines, thereby decreasing the overall energy demand for producing PP hollow boards. Furthermore, the machine is engineered to minimize waste, ensuring that less material is discarded into landfills.

In summary, the PP hollow board extrusion line stands out as a premier solution that offers outstanding performance, dependability, and user-friendliness. Featuring cutting-edge technology, remarkable versatility, and intuitive operation, it represents an excellent choice for professionals in the packaging sector who aim to manufacture high-quality PP hollow boards tailored to the unique requirements of their clients, all while reducing their environmental footprint.

Parameter

| Co-extrusion GWS120+GWS75,GWS150+GWS90 | |

| PP | PP |

| 1830mm | 915/1220mm |

| 12mm-21mm | |

| 250-400kg/h | |

| Advertising,Transportation,Construction template,Portable partition. | |

With years of experience in manufacturing plastic hollow sheet extruder production lines in China, China GWELL will provide you with high-quality services and high-quality after-sales services including technical support, technical inspection and training, so that you can rest assured that with our professional capabilities, With the quality performance of GWELL manufacturers, it will definitely bring satisfactory results!

Application

- Hollow board: PP hollow board extrusion line products mainly replace the ideal materials such as corrugated cardboard, wood board and metal plate.

- Turnover boxes: spare parts turnover boxes, food turnover boxes, beverage turnover boxes, pesticide packaging boxes, inner packaging of precision instruments, pads, partitions and transportation storage turnover boxes for electronic components packaging.

- Industrial boards: outer packaging protection of various items, pads, racks, partitions, bottom plates, cross plates, etc.

- Electronic industry packaging: Conductive packaging products are mainly used in the packaging of electronic parts, the purpose is to avoid contact with other charged items, causing spark damage to parts due to electric friction. In addition, there are conductive and antistatic plastic plates, turnover boxes and so on.

- Advertising decoration: display boards, commodity identification boards, billboards, light boxes, window shapes, etc.

- Household use: temporary partitions of residences, wall panels, ceiling panels, container covers, etc.

- Others: PP hollow board extrusion line products are used for backboards of washing machines, automobiles, water heaters, baby carriages, etc., packing, storage and transportation pads, etc. PP plastic hollow board is a new type of packaging material, which is produced by PP pelletized material and extruded at high temperature.

Client

About Gwell

Innovation drives enterprise progress. Relying on the group’s strong technology, equipment strength and innovation spirit, Gwell is committed to the development of high-tech products and the international market. Gwell also actively exchanges and cooperates with world-class scientific research institutions. The new technologies, new processes and new products developed by Gwell are widely used in building materials(PP hollow sheet extrusion machine, PC optic extrusion machine), home appliances(SPC floor extrusion machine), packaging(PET sheet extrusion machine, EVOH film extrusion machine),

medical treatment(PVC rigid sheet extrusion machine), automobiles(TPU film extrusion machine, PVB film extrusion machine), new energy(EVA solar film extrusion machine), aerospace(TPU film extrusion machine), rail transit(waterproof film extrusion machine) and other fields, which are closely related to human life.

Related Product

The main components of the PC Sheet extrusion production line are selected from the world’s high-quality products (such as screws, barrels, rollers, etc.), and its production process is comprehensive. As an excellent supplier of plastic extruders, GWELL’s complete set of production line has approached the world’s high-quality product standards.

As a premier Chinese manufacturer of plastic extrusion machinery, GWELL delivers cutting-edge PS (Polystyrene) Sheet Extrusion Lines engineered for precision, efficiency, and unmatched product consistency. Our advanced extrusion systems are designed to meet the rigorous demands of diverse industries, offering tailored solutions for high-quality PS sheet production.

As a pioneer in PVB interlayer film production machine technology, we specialize in delivering cutting-edge systems designed for high-performance PVB interlayer film manufacturing. Our PVB interlayer film production machines are engineered to meet global industry standards, combining precision, efficiency, and sustainability.

FAQ

What is the main business of GWELL?

Can I go on a field trip to the GWELL factory?

What are the services for purchasing equipment at GWELL?

What types of plastic extrusion machines are available from GWELL?

What is APET PETG CPET Sheet Extrusion Line?

Where does GWELL ship from?

Are there any technical supports for extrusion machine that you need?

Our service will be always at your disposal over the entire extrusion line life.So if you want to know about any other technical supports.Please contact us as soon as possible.