PP Sheet Extrusion Line

The PP Sheet Extrusion Line is your gateway to efficient and high-quality polypropylene sheet production. This state-of-the-art equipment ensures precision, consistency, and cost-effectiveness in crafting PP sheets for various applications. Upgrade your manufacturing with this advanced extrusion line.

Key words:Sheet Extrusion Line

Category:

Sheet Extrusion Line

Download:

Description

Process Flows

PP Sheet Extrusion Line

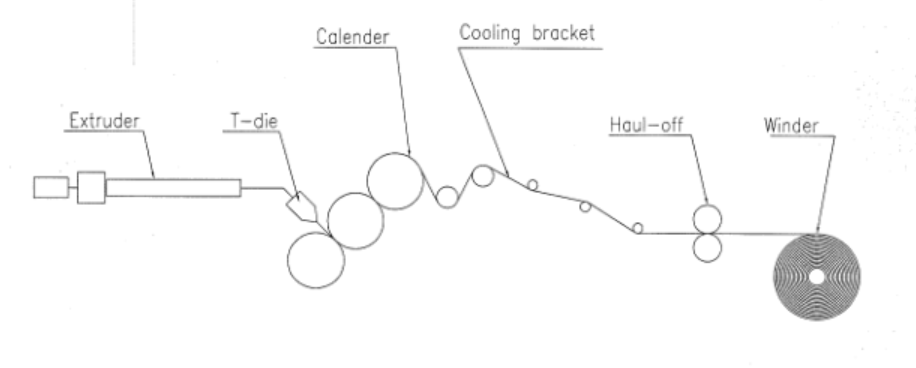

Extruder —- Screen changer —–Melt pump —– T-die —— Calender —– Cooling bracket —– Haul-off—- winder

GWELL, a leading Chinese plastic extruder manufacturer, employs versatile co-extrusion technologies utilizing single, dual, or multiple extruders to manufacture composite PP sheets across diverse structural configurations. Our production capabilities span from single-layer and double-layer sheets to multi-layer composites, with predominant configurations including five-layer, seven-layer, and nine-layer architectures. These extruded sheets serve critical applications in thermoforming, printing, hardware packaging, and consumer goods industries such as food packaging, apparel, stationery, and toy manufacturing.

The extrusion systems feature adaptable configurations with either single-screw or parallel twin-screw extruders, delivering precise dimensional outputs:

-

Sheet width: 600mm to 1220mm

-

Thickness: 0.15mm to 3mm

-

Production capacity: 200kg/h to 1000kg/h

Engineered for operational reliability, the equipment ensures stable material feeding across diverse formulations while achieving superior raw material plasticization. This processing excellence guarantees enhanced sheet durability while eliminating downstream production challenges such as thermoforming defects, structural cracking, and chromatic inconsistencies.

PP sheet production line process principle

Plastic pellet – extruder: raw material melting and plasticization – quick change filter screen – extrusion die forming extrusion – three-roll calender – cooling setting device – trimming mechanism – traction conveyor – Shearing device or winding device

Production line composition

Screw extruder, screen changers, metering pumps and molds, three-roll calenders, cooling brackets, tractors, shears or winders.

Advantage

1. Equipped with precision distributor, uniform layering, adjustable proportion of each layer, digital precise control.

2. The temperature of the roller can be adjusted, and the surface gloss of the sheet is high.

3. High output, using oven, sheet is not easy to curl after cutting.

4. The whole line adopts man-machine interface display, and the whole machine adopts PLC control to realize automatic control of parameter setting, data calculation and feedback, alarm and other functions, and the management operation is more convenient.

5. Gwell independently writes the electronic control operating system.

Parameter

| Type of extrusion line | single screw venting PP/PS sheet extrusion line | twin screw venting PP/PS sheet extrusion line | ||

| Extrusion type | Mono extruded or co-extruded | |||

| Finished Product | Single layer, double-layer or multi-layer PET sheet | |||

| Raw material | PP/PS vergin ,flake and crushed material | |||

| Net width | 600mm-1220mm and more | |||

| Thickness range | 0.15mm-2mm and more | |||

| Capacity | 200kg/h-1200kg/h and more | |||

| Application | Food and fruit packing,Stationery pieces,Printing, hardware packing,electronic tray,flocking,clothing,decorative pieces,high barrier packing and more | |||

| Type of extrusion line | PP/PS single-extruder extrusion line | PP/PS double-extruder Co-extrusion line | PP/PS multi-extruder co-extrusion multi-layer sheet extrusion line |

| Can produce single layer sheet | Can produce double-layer or three-layer sheet | Can produce multi-layer sheet, which usually has 5 layers, 7 layers or 9 layers | |

| Type of extruder | Single screw extruder or parallel twin screw extruder | ||

| Width of Products | 600mm-1220mm | ||

| Thickness of Products | 0.15mm-3mm | ||

| Output | 200kg/h-1000kg/h | ||

Application

PP sheet can be made into various products through secondary processing forms such as thermoforming, mainly used for food, medicine, medical equipment and other packaging. Such as processed frozen boxes, dairy packaging boxes, fast food boxes, cold drink containers, trays, microwave utensils, etc. can be used for food packaging; Processing into blisters can be used for the packaging of solid preparations such as pharmaceutical tablets, capsules, etc. In foreign countries, especially in developed countries and regions, transparent PP sheet is widely used in food packaging and other fields.

Client

About Gwell

Innovation drives enterprise progress. Relying on the group’s strong technology, equipment strength and innovation spirit, Gwell is committed to the development of high-tech products and the international market. Gwell also actively exchanges and cooperates with world-class scientific research institutions. The new technologies, new processes and new products developed by Gwell are widely used in building materials(PP hollow sheet extrusion machine, PC optic extrusion machine), home appliances(SPC floor extrusion machine), packaging(PET sheet extrusion machine, EVOH film extrusion machine),

medical treatment(PVC rigid sheet extrusion machine), automobiles(TPU film extrusion machine, PVB film extrusion machine), new energy(EVA solar film extrusion machine), aerospace(TPU film extrusion machine), rail transit(waterproof film extrusion machine) and other fields, which are closely related to human life.

Related Product

The main components of the PC Sheet extrusion production line are selected from the world’s high-quality products (such as screws, barrels, rollers, etc.), and its production process is comprehensive. As an excellent supplier of plastic extruders, GWELL’s complete set of production line has approached the world’s high-quality product standards.

As a premier Chinese manufacturer of plastic extrusion machinery, GWELL delivers cutting-edge PS (Polystyrene) Sheet Extrusion Lines engineered for precision, efficiency, and unmatched product consistency. Our advanced extrusion systems are designed to meet the rigorous demands of diverse industries, offering tailored solutions for high-quality PS sheet production.

As a pioneer in PVB interlayer film production machine technology, we specialize in delivering cutting-edge systems designed for high-performance PVB interlayer film manufacturing. Our PVB interlayer film production machines are engineered to meet global industry standards, combining precision, efficiency, and sustainability.

FAQ

What is the main business of GWELL?

Can I go on a field trip to the GWELL factory?

What are the services for purchasing equipment at GWELL?

What types of plastic extrusion machines are available from GWELL?

What is APET PETG CPET Sheet Extrusion Line?

Where does GWELL ship from?

Are there any technical supports for extrusion machine that you need?

Our service will be always at your disposal over the entire extrusion line life.So if you want to know about any other technical supports.Please contact us as soon as possible.