EPE Solar Film Extrusion Line

Prior to the advent of EVA/POE/EPE solar film extrusion lines, market demand primarily focused on separate EVA and POE solar film production equipment. However, growing market volatility and cost pressures drove increasing customer demand for integrated solutions that could combine EVA's performance characteristics with POE's advantages while reducing raw material costs. Responding to these evolving market needs, GWELL - as a leading Chinese plastic extrusion machinery manufacturer - pioneered the world's first EPE solar film extrusion line, a groundbreaking innovation that successfully merged the benefits of both materials while optimizing production economics. This technological breakthrough rapidly gained global recognition and widespread adoption across the solar industry, establishing EPE extrusion lines as the new standard for photovoltaic encapsulation film production.

Key words:Sheet Extrusion Line

Category:

EVA POE solar film extrusion line

Description

The Evolution of Solar Film Extrusion: How GWELL Pioneered EPE Technology

The Market Challenge

Historically, solar manufacturers relied on separate EVA and POE film production lines. But market volatility created new demands:

✓ Cost reduction through optimized raw material usage

✓ Combined performance benefits of EVA and POE in one film

✓ Production flexibility to adapt to changing material economics

The GWELL Breakthrough

Partnering with forward-thinking manufacturers, we developed the world's first EPE Solar Film Extrusion Line - a revolutionary solution that:

✔ Unifies the best properties of EVA and POE

✔ Reduces material costs by up to 20%

✔ Maintains exceptional encapsulation performance

Global Impact

Since its introduction, our EPE technology has become the industry benchmark, adopted by leading solar manufacturers worldwide for its:

• Production efficiency

• Superior film quality

• Unmatched cost-performance ratio

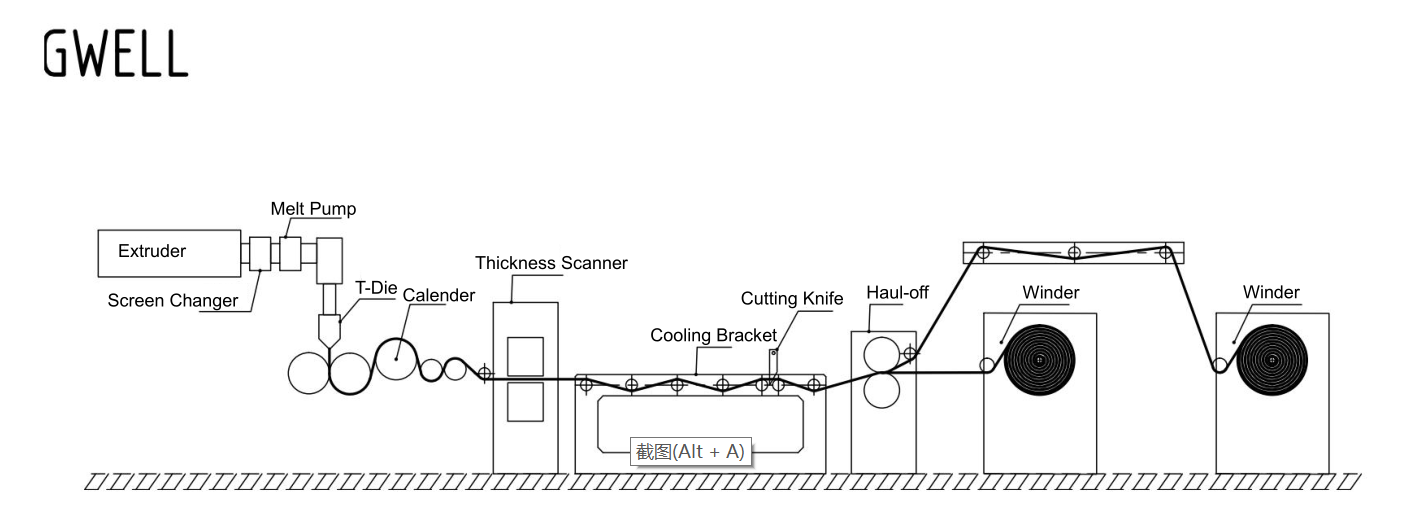

EPE solar film extrusion line Process Flows

Extruder —- Screen changer —– Melt pump —– T-die —— Calender —– Thickness Scanner —-Cooling Bracket —-Cuttting Knife —- Haul-off —-Winder

Features of Gwell’s EPE(EVA/POE/EVA) solar film extrusion line

- Film Layers structure: According to the finished film, EVA/POE/EVA film has three layers(EPE film). It will be based on the customer requirements, EPE solar film extrusion line can also produce EVA or POE single layer.

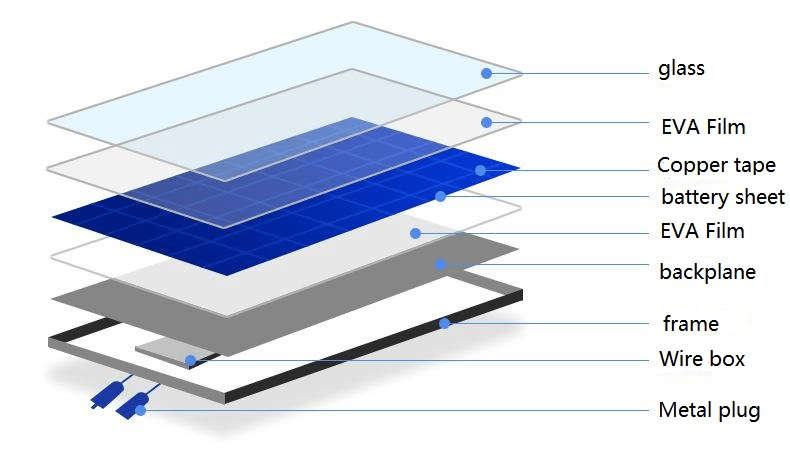

- China EVA / POE / EPE solar film is used for solar cell encapsulation. After lamination and curing, it is bonded and sealed. It plays the role of high light transmittance, preventing water vapor penetration, high and low-temperature resistance, and ultraviolet light resistance to ensure the stable and efficient use of battery modules. It is a durable and reliable packaging material. The EVA / POE / EPE packaging film extrusion line of Gwell machinery is in a leading position in the world.

Advantages of the Gwell EPE(EVA/POE/EVA) solar film extrusion line

- EPE solar film extrusion production line currently has a global market share of 90%, including China, the United States, India, Turkey, Sri Lanka, etc.

- If EPE film is produced, the speed can reach 12m/min-15m/min, if it is EVA, it can reach 15-18m/min, and if it is POE, it can reach 10-13m/min.

- Cooling parts to ensure shrinkage rate is less than 3%.

- GWELL special winder to ensure micro-tension, and achieve automatic winding and cutting.

Comparison of the Gwell EPE(EVA/POE/EVA) solar film and EVA solar film and POE solar film

- Transparent EVA solar film: with high light transmittance, it is used for bonding glass and cells; The raw materials are EVA resin and various modifiers, which are cheaper.

- White EVA solar film: compared with transparent EVA solar film, the pretreatment of white fillers such as titanium dioxide is added. It has a strong barrier, low light transmittance, and high reflectivity, which can improve the power generation of components. It has strong resistance to damp-heat aging and ultraviolet aging and can inhibit the aging and cracking of the back sheet.

- Poe solar film: Poe solar film has a higher water vapor barrier rate and stronger anti-PID performance so the module can be used for a long time. It is the main packaging adhesive film of a double-sided double glass module and film module at present.

- EPE(EVA/POE/EVA)solar film: It has both the anti-PID performance of POE and lamination efficiency of EVA solar film and reduces the use of POE particles to achieve cost reduction and efficiency increase. At present, it is mainly used in high-efficiency components.

From the perspective of the production process, the main process flow of transparent EVA film, white EVA film, and POE film includes batching, mixing, extrusion, shaping, slitting, and packaging. The process is roughly the same, the extrusion line is basically compatible, and can be converted to each other through technology transformation. When it comes to the production process, the first step is batching. This involves carefully measuring and combining the necessary raw materials in the correct proportions. Once the materials are batched, they move on to the mixing stage. Here, the materials are thoroughly blended together to ensure a uniform composition. The next stage in the process is extrusion. During extrusion, the mixed materials are heated and forced through a die to create a continuous film. This film is then shaped into the desired form, whether it be transparent EVA film, white EVA film, or POE film. After shaping, the film is slit into the appropriate width and length. This is an important step in ensuring that the final product meets the specifications required by customers. Finally, the film is packaged and prepared for distribution. Overall, while there may be slight variations in the production process for transparent EVA film, white EVA film, and POE film, the core steps remain the same. The extrusion line is versatile and can be easily adapted to produce different types of film through technology transformation. This flexibility allows manufacturers to efficiently switch between products and meet the diverse needs of their customers.

The future of the EVA/POE/EPE solar film market

Market Dynamics Driving EPE Solar Film Extrusion Line Expansion

1. Photovoltaic Capacity Surge as Key Catalyst

The global PV market is experiencing unprecedented growth, with China leading installations (accounting for ~40% of global capacity in 2024). This expansion directly fuels demand for advanced encapsulation materials like EPE films, which offer:

Cost efficiency: 15-20% lower material costs vs. traditional EVA/POE solutions [industry data]

Performance synergy: Combines EVA's adhesion strength with POE's anti-PID properties

Supply chain resilience: Simplified production through single-line processing

2. Policy Tailwinds Accelerating Adoption

Global carbon neutrality commitments are reshaping energy policies:

• China's 14th Five-Year Plan targets 1,200GW renewable capacity by 2030

• EU's REPowerEU mandates 45% renewable energy share by 2030

• US Inflation Reduction Act provides $370B clean energy incentives

These measures create a $12B+ addressable market for solar encapsulation films by 2030

3. Technological Economics Favoring EPE

As PV LCOE drops below $0.03/kWh in sun-rich regions, the industry prioritizes:

✓ Higher yield: EPE lines achieve <1% material waste vs. 3-5% for conventional systems

✓ Faster ROI: Integrated production cuts capex by 18% over separate EVA/POE lines

✓ Future-readiness: Compatible with next-gen TOPCon/HJT cell architectures

Parameter

| Extruder Type | Co-extrusion GWS160+GWS160 | Co-extrusion GWS180+GWS160 | Co-extrusion GWS180+GWS180 |

| Raw material | EVA, POE | ||

| Layers | EVA,POE,EVA/POE/EVA three layers(EPE) | ||

| Net width | 2200mm-2600mm | ||

| Thickness range | 0.2mm-1mm | ||

| Max linear speed | 15m/min-18m/min | ||

| Application | EVA、POE、EPE film for solar encapsulation | ||

Application

EPE solar film extrusion line application

Because of EPE(EVA/POE/EVA) film superior adhesion,durability and optical characteristicas,which is maily used for

- crystalline silicon and solar module encapsulation for PV.

- dressing in the field.

- optical products.

EVA glass laminated film is widely used in

Deep processing of safety flat laminated glass, arc laminated glass, process laminated glass, bulletproof glass, color changing laminated glass, conductive smart glass, solar cell and other special glass.

EVA hot melt adhesive casting film and embossing film are widely used in

Sanitary products: medical surgical clothes, baby diaper film, women’s sanitary napkin bottom film, adult diaper film, pet pad film, disposable bed sheets, etc.

Daily necessities: umbrella, raincoat, suit coat, all kinds of tablecloth, shower cap, shower curtain, apron, chair cover, etc.

Packaging supplies: dust cover for computer and electrical appliances, soft packaging for cosmetics, shopping bags, gift bags, file bags, etc.

Client

About Gwell

Innovation drives enterprise progress. Relying on the group’s strong technology, equipment strength and innovation spirit, Gwell is committed to the development of high-tech products and the international market. Gwell also actively exchanges and cooperates with world-class scientific research institutions. The new technologies, new processes and new products developed by Gwell are widely used in building materials(PP hollow sheet extrusion machine, PC optic extrusion machine), home appliances(SPC floor extrusion machine), packaging(PET sheet extrusion machine, EVOH film extrusion machine),

medical treatment(PVC rigid sheet extrusion machine), automobiles(TPU film extrusion machine, PVB film extrusion machine), new energy(EVA solar film extrusion machine), aerospace(TPU film extrusion machine), rail transit(waterproof film extrusion machine) and other fields, which are closely related to human life.

Related Product

The main components of the PC Sheet extrusion production line are selected from the world’s high-quality products (such as screws, barrels, rollers, etc.), and its production process is comprehensive. As an excellent supplier of plastic extruders, GWELL’s complete set of production line has approached the world’s high-quality product standards.

As a premier Chinese manufacturer of plastic extrusion machinery, GWELL delivers cutting-edge PS (Polystyrene) Sheet Extrusion Lines engineered for precision, efficiency, and unmatched product consistency. Our advanced extrusion systems are designed to meet the rigorous demands of diverse industries, offering tailored solutions for high-quality PS sheet production.

As a pioneer in PVB interlayer film production machine technology, we specialize in delivering cutting-edge systems designed for high-performance PVB interlayer film manufacturing. Our PVB interlayer film production machines are engineered to meet global industry standards, combining precision, efficiency, and sustainability.

FAQ

What is the main business of GWELL?

Can I go on a field trip to the GWELL factory?

What are the services for purchasing equipment at GWELL?

What types of plastic extrusion machines are available from GWELL?

What is APET PETG CPET Sheet Extrusion Line?

Where does GWELL ship from?

Are there any technical supports for extrusion machine that you need?

Our service will be always at your disposal over the entire extrusion line life.So if you want to know about any other technical supports.Please contact us as soon as possible.