PVC Foaming Board Extrusion Line

China GWELL as China Plastic Extruder manufacturer, PVC foaming board extrusion line adopts srl-z series hot and cold mixing unit for material mixing. The mixing process of the materials is very important. The quality of the mixture will directly affect the extrusion process and the appearance and internal quality of the sheet.

Key words:Sheet Extrusion Line

Category:

Foaming Extrusion Line

Download:

Description

PVC foaming board extrusion line Mixing process

China GWELL as extruder manufacturer, PVC skin foam, semi-skin foam, co-extruded core foam sheet production line, consisting of a dedicated conical twin-screw extruder, sheet dies, setting table (three rolls), and auxiliary machines composition. The equipment has the characteristics of large output, stable extrusion, high foaming ratio, smooth surface, and wear resistance. Various imitation wood products can also be produced through printing, filming, and hot pressing equipment, which are widely used. China GWELL can provide a full range of formulations and process technologies.

China GWELL PVC skin foam board, co-extruded core skin foam board, has excellent corrosion resistance, insulation, and particular mechanical strength. Widely used in passenger cars, train car ceilings, box core layers, interior decorative panels, building exterior wall panels, interior decorative panels, office, residential, public building compartments, commercial decorative frames, clean room panels, ceiling panels, screen printing, computer lettering, advertising signs, exhibition panels, photo album panels for signs and other industries and chemical anti-corrosion engineering, thermoforming parts, cold storage panels, exceptional cold insulation engineering, environmental protection molds, sports equipment, aquaculture materials, seashore moisture-proof facilities, water-resistant materials, art materials, and various lightweight clapboards instead of glass ceilings.

China GWELL PVC free foam board is also known as Chevron board and Andy board, and its chemical composition is polyvinyl chloride. The surface hardness of PVC free foam board is average; its chemical properties are stable, acid, alkali, corrosion resistance, thermal insulation. Widely used in advertising display boards, mounting boards, silk screen printing, engraving, etc.

China GWELL PVC building formwork production line uses PVC waste plastic and wood powder, calcium carbonate, and other fillers to manufacture plastic building formwork through the extrusion process. It is a new formwork that replaces steel formwork and bamboo wood plywood. PVC wood-plastic building formwork has many advantages such as low cost, light weight, and reusability. At the same time, the waste can be crushed and reused. The use of PVC building templates is the same as that of wooden templates. Due to its plastic material and unique production process, the turnover of PVC building templates can be used more than 30 times, and the wholly scrapped plates can still be recycled and processed into new building templates. The use cost is relatively low.

Due to the weak mixing function of the counter-rotating twin-screw extruder, batching, hot mixing and cold mixing processes should be set before extrusion.

The PVC foaming board extrusion line adopts srl-z series hot and cold mixing unit for material mixing. The mixing process of materials is very important. The quality of material mixing will directly affect the extrusion process and the appearance and internal quality of plates.

If the mixing temperature of materials is too high or too low, the materials will decompose in advance or plasticize poorly.

Therefore, the control of mixing procedure and temperature is the key of mixing process.

The general production feeding sequence is PVC, stabilizer, internal lubricant, processing aid, filler, external lubricant and titanium dioxide.

The input amount is about 60% of the effective volume of the hot mixing cylinder.

The high-speed hot mixing temperature is controlled within 110 ~ 120 ℃ for 5 ~ 10 min, the cooling mixing water temperature is below 15 ~ 20 ℃, and the cold mixed materials are discharged from the mixer at 35 ~ 40 ℃ after 5 ~ 10 min.

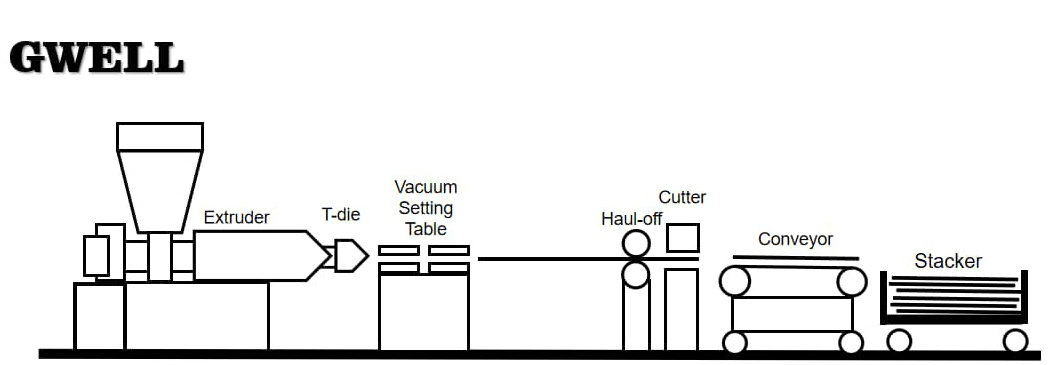

PVC foaming board extrusion line process flow

PVC resin + additives → high-speed mixing → low-speed cold mixing → conical twin-screw extrusion → die shaping (skinned foam) → cooling and setting → multi cot traction → cutting products → collection and inspection.

Extruder —– T-die —— Calender —– Cooling bracket —– Haul-off—- Cutter —— Conveyor —– Stacker

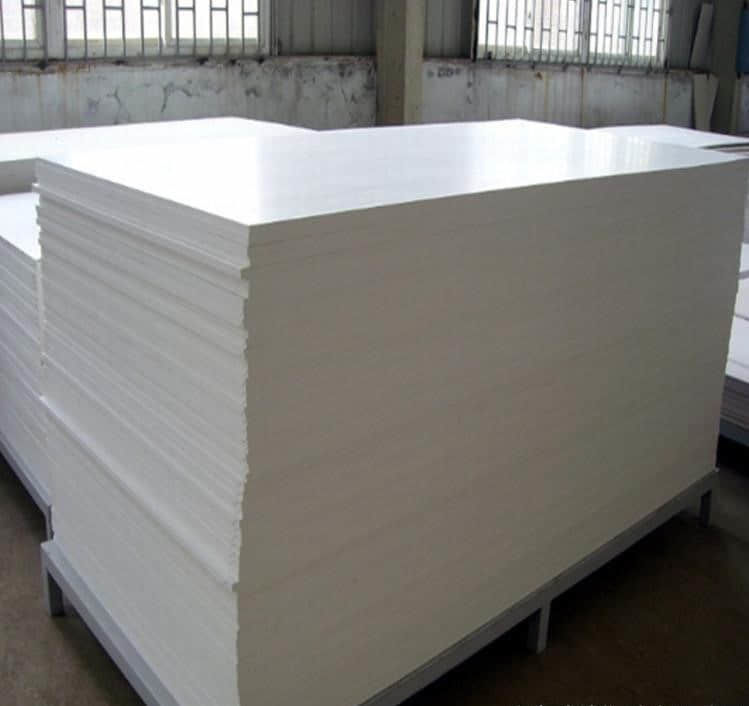

PVC foam board, also known as chevron board or Andy board, can be divided into PVC skinned foam board and free foam board according to the manufacturing process, appearance and performance.

China GWELL, PVC laminated foam board is produced by such process, the surface has a hard skin, smooth and flat, high hardness, good mechanical properties, high product precision, small thickness error, strict requirements on mold, formula, process and raw materials.

PVC free foaming board has loose surface, no crust, and presents fine concave convex pitted surface, which is conducive to printing, spraying and veneering. It can be produced with ordinary foaming mold, and the process is relatively easy to control.

Parameter

| PVC foaming board line type | PVC Free Foaming Board Extrusion Line | PVC Skinning Foaming Board Extrusion line | Co-extrusion PVC Skinning Foaming Board Extrusion line |

| Extruder Type | GWC80/156 | GWC80/156 | GWC80/156; GWC65/132 |

| Net width | 1220mm | ||

| Thickness range | 2-18mm | 5-20mm | 5-20mm |

| Capacity | 350-450kg/h | 350-450kg/h | 450-500kg/h |

Application

Practice has proved that the PVC foam board produced by GWELL as China Plastic Extruder manufacturer has good thermal insulation, thermal insulation, sound insulation, light load-bearing and other properties, and is superior to other lightweight solid plastic expanded perlite, ceramsite, asbestos products and other thermal insulation materials.

It has the characteristics of simple operation, high degree of mechanization, time-saving and labor-saving.

PVC foam board can be transported by mechanical vertical pipeline, which shortens the working hours and improves the work efficiency by 6 ~ 10 times compared with other methods.

PVC foam board is used as the insulation layer for roof insulation and exterior wall insulation.

It has incomparable insulation performance and adhesion performance to the structural layer.

It also has many advantages such as convenient construction, environmental protection, time saving and efficiency increase.

It can be used to replace polystyrene (benzene board) and other insulation materials.

PVC foam board is also used to make PVC foam board bricks in southern China to achieve the purpose of roof insulation and exterior wall insulation.

Client

About Gwell

Innovation drives enterprise progress. Relying on the group’s strong technology, equipment strength and innovation spirit, Gwell is committed to the development of high-tech products and the international market. Gwell also actively exchanges and cooperates with world-class scientific research institutions. The new technologies, new processes and new products developed by Gwell are widely used in building materials(PP hollow sheet extrusion machine, PC optic extrusion machine), home appliances(SPC floor extrusion machine), packaging(PET sheet extrusion machine, EVOH film extrusion machine),

medical treatment(PVC rigid sheet extrusion machine), automobiles(TPU film extrusion machine, PVB film extrusion machine), new energy(EVA solar film extrusion machine), aerospace(TPU film extrusion machine), rail transit(waterproof film extrusion machine) and other fields, which are closely related to human life.

Related Product

The main components of the PC Sheet extrusion production line are selected from the world’s high-quality products (such as screws, barrels, rollers, etc.), and its production process is comprehensive. As an excellent supplier of plastic extruders, GWELL’s complete set of production line has approached the world’s high-quality product standards.

As a premier Chinese manufacturer of plastic extrusion machinery, GWELL delivers cutting-edge PS (Polystyrene) Sheet Extrusion Lines engineered for precision, efficiency, and unmatched product consistency. Our advanced extrusion systems are designed to meet the rigorous demands of diverse industries, offering tailored solutions for high-quality PS sheet production.

As a pioneer in PVB interlayer film production machine technology, we specialize in delivering cutting-edge systems designed for high-performance PVB interlayer film manufacturing. Our PVB interlayer film production machines are engineered to meet global industry standards, combining precision, efficiency, and sustainability.

FAQ

What is the main business of GWELL?

Can I go on a field trip to the GWELL factory?

What are the services for purchasing equipment at GWELL?

What types of plastic extrusion machines are available from GWELL?

What is APET PETG CPET Sheet Extrusion Line?

Where does GWELL ship from?

Are there any technical supports for extrusion machine that you need?

Our service will be always at your disposal over the entire extrusion line life.So if you want to know about any other technical supports.Please contact us as soon as possible.

Previous

下一页