TPU Laminating Extrusion Line

Our TPU film production line, ranging from 1372-1520mm in width and 0.02-3.0mm in thickness, ensures precise temperature control and high transparency. The TPU laminating extrusion line efficiently combines TPU film with fabrics, reducing costs and enhancing product quality across diverse applications.

Key words:Sheet Extrusion Line

Category:

Film Extrusion Line

Download:

Description

Introduction

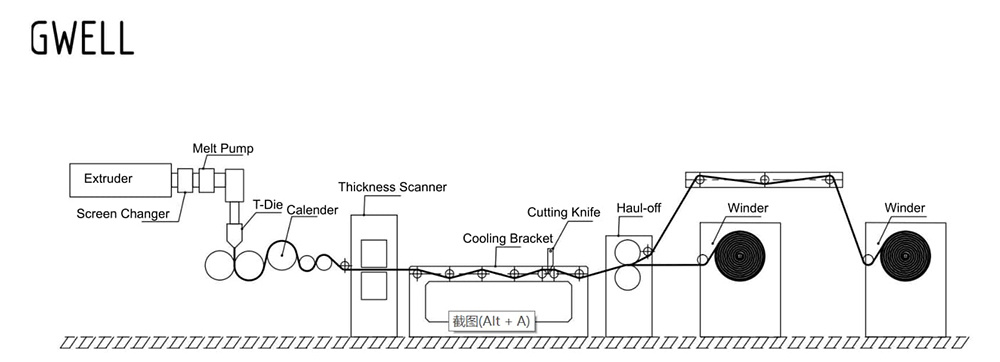

TPU is a kind of thermoplastic TPU elastomer, TPU film is made of TPU granules by casting process, our TPU film production line not only combines the company’s experience over the years, but also draws on the production experience of many TPU manufacturers, continuous improvement and innovation. The width range of the TPU produced by this equipment is 1372-1520mm, and the thickness range is 0.02-3.0mm. One or more single screw extruder can be used for co-extrusion, and each extruder is divided into 8 temperature control zones for precise temperature control. Up to 600KG/H in single-layer, A/B/A or A/B distribution modes. By utilizing PLC for overall control, it is possible for a single individual to effortlessly manage operations. The main components are designed for simple disassembly and replacement, with a remote control port reserved for enabling synchronous monitoring from various locations worldwide. Although the initial cost may be significant, the benefits far outweigh the expense. The items produced using our machinery exhibit exceptional transparency, minimal crystal points, and a complete absence of bubbles during the winding process.

Our TPU film coating composite production line is designed to extrude TPU film onto a wide range of fabrics in order to achieve single-sided or double-sided online composite molding. This process eliminates the need for traditional offline gluing, which typically involves two or three separate composite steps. By streamlining the production process, our production line not only reduces costs and increases efficiency, but also enhances the strength and overall quality of the final composite products.

Parameter

| Extruder Type | GWS90 | GWS120 | GWS150 |

| Film layers | single layer, double layers or three layers | ||

| Raw material | TPU | ||

| Net width | 1300-1600mm | 1300-1600mm | 1300-2000 |

| Thickness range | 0.3-2mm | 0.3-3mm | 1-5mm |

| Capacity | 150-180kg/h | 250-300kg/h | 350-500kg/h |

Application

TPU film not only has excellent tensile, tensile, toughness and aging resistance characteristics, but also is a mature environmental protection material. At present, TPU has been widely used in: footwear, clothing, inflatable toys, water and underwater sports equipment, medical equipment, fitness equipment, car seat materials, umbrellas, suitcases, leather bags, car clothing coating and so on. Waterproof and moisture-permeable TPU film is used with various fabrics to achieve the effect of waterproof and moisture-permeable, and is the main material of hardshell clothing.

Client

About Gwell

Innovation drives enterprise progress. Relying on the group’s strong technology, equipment strength and innovation spirit, Gwell is committed to the development of high-tech products and the international market. Gwell also actively exchanges and cooperates with world-class scientific research institutions. The new technologies, new processes and new products developed by Gwell are widely used in building materials(PP hollow sheet extrusion machine, PC optic extrusion machine), home appliances(SPC floor extrusion machine), packaging(PET sheet extrusion machine, EVOH film extrusion machine),

medical treatment(PVC rigid sheet extrusion machine), automobiles(TPU film extrusion machine, PVB film extrusion machine), new energy(EVA solar film extrusion machine), aerospace(TPU film extrusion machine), rail transit(waterproof film extrusion machine) and other fields, which are closely related to human life.

Related Product

The main components of the PC Sheet extrusion production line are selected from the world’s high-quality products (such as screws, barrels, rollers, etc.), and its production process is comprehensive. As an excellent supplier of plastic extruders, GWELL’s complete set of production line has approached the world’s high-quality product standards.

As a premier Chinese manufacturer of plastic extrusion machinery, GWELL delivers cutting-edge PS (Polystyrene) Sheet Extrusion Lines engineered for precision, efficiency, and unmatched product consistency. Our advanced extrusion systems are designed to meet the rigorous demands of diverse industries, offering tailored solutions for high-quality PS sheet production.

As a pioneer in PVB interlayer film production machine technology, we specialize in delivering cutting-edge systems designed for high-performance PVB interlayer film manufacturing. Our PVB interlayer film production machines are engineered to meet global industry standards, combining precision, efficiency, and sustainability.

FAQ

What is the main business of GWELL?

Can I go on a field trip to the GWELL factory?

What are the services for purchasing equipment at GWELL?

What types of plastic extrusion machines are available from GWELL?

What is APET PETG CPET Sheet Extrusion Line?

Where does GWELL ship from?

Are there any technical supports for extrusion machine that you need?

Our service will be always at your disposal over the entire extrusion line life.So if you want to know about any other technical supports.Please contact us as soon as possible.

Previous