PP, Evoh Multi-Layer Barrier Sheet Extrusion Line

pp, evoh multi-layer barrier sheet extrusion line: Due to the increasingly stringent requirements of the market for products, the advanced five-layer symmetric and seven-layer asymmetric distribution technology has been developed, so that the products produced by this equipment have better barrier performance. At present, GWELL can integrate EVOH into 7-layer, 9-layer or 11-layer structure through multi-layer co-extrusion process.

Key words:Sheet Extrusion Line

Category:

Sheet Extrusion Line

Download:

Description

Pp evoh multi-layer barrier sheet extrusion line introduction

pp evoh multi-layer barrier sheet extrusion line: Due to the increasingly stringent requirements of the market for products, the advanced five-layer symmetric and seven-layer asymmetric distribution technology has been developed, so that the products produced by this equipment have better barrier performance.

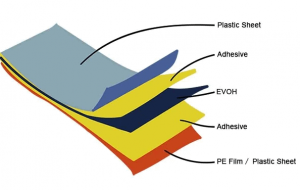

At present, GWELL can integrate EVOH into 7-layer, 9-layer, or 11-layer structure through multi-layer co-extrusion process. Multilayer coextrusion is a process in which two or more plastic materials are extruded as one material. In a standard single-layer sheet extrusion process, one material is fed and extruded through a die. The co-extrusion process involves multiple extruders and multiple materials (depending on the structure), laminar flow of molten material through melt pipes for co-extrusion feed blocks, and die technology to weld the extrudates into a unitary structure.

The structure of multi-layer co-extrusion sheet can be divided into two types, namely symmetrical structure (A/B/A) and asymmetrical structure (A/B/C). Most of them are on the 5th, 7th, 8th, and 9th floors. The structural layers of multilayer coextruded sheets consist of three types of functional layers: barrier layer, adhesive layer, and support layer.

pp evoh multi-layer barrier sheet extrusion line, this series of plastic sheet extrusion line is mainly used to produce extruded sheets of PE, EVOH, PA, EVA, PS, PP and other materials. It is equipped with a single-screw extruder that heats, shears and conveys the material to extrusion dies and other forming and cooling equipment to achieve the final shape and size. Depending on the type of material to be extruded, different screw designs with specific length-to-diameter ratios are selected, as well as suitable extrusion dies.

Pp evoh multi-layer barrier sheet extrusion line process

1. Extrude

2. Molding using an extrusion die

3. Cooling and shaping under vacuum or normal operating conditions to obtain the final shape

4. Delivery

5. Cutting

6. Discharge

Pp evoh multi-layer barrier sheet extrusion line part

Conical twin-screw extruder, vacuum calibrating table, conveyor belt, cutter, film laminating machine, tilting frame, etc.

Advantage

- The optimized design of pp evoh multi-layer barrier sheet extrusion line equipment is very important to the production operation. The extruded sheet production line is manufactured by the world’s new technology, which has many advantages such as uniform plasticization, low shear rate, high productivity, and long service life.

- The sheet production line equipment has the characteristics of compact structure, superior performance, high degree of automation, and stable operation.

- The main extrusion equipment is driven by imported AC or DC speed regulation. Adopt Japanese RKC temperature controller for temperature control. Auxiliary equipment is equipped with famous brand vacuum pump and traction motor.

- All these parts are easy to maintain and repair.

- The produced PP and PE boards are impact-resistant, corrosion-resistant, high heat-resistant, non-toxic, tasteless, smooth and beautiful, and the processing procedures are easy to operate. The produced boards will not produce poisonous gas during welding.

- The resulting 5-layer or 7-layer PE, EVOH, PV, EVA, PS or pp ps sheet extrusion line PP sheet provides good air and a moisture-proof layer for the food wrapped in it. It traps air between the layers, providing the best possible protection for the food.

Pp evoh multi-layer barrier sheet extrusion line application

- Store fresh meat at room temperature

- Frozen stored meat

- Other fresh food

- Snacks

- Some industrial products

- Medical device packaging

What is EVOH

EVOH stands for ethylene vinyl alcohol copolymer and is a flexible, crystal clear, glossy thermoplastic copolymer. This material has excellent flex crack resistance and high resistance to hydrocarbons, oils, and organic solvents. EVOH is known for having the best barrier properties against gases such as oxygen, nitrogen, and carbon dioxide, and EVOH is considered to have excellent barrier properties compared to other common films. However, EVOH loses its good gas barrier properties when exposed to moisture. Therefore, EVOH is often used in multi-layer co-extruded film structures together with materials such as HDPE, PP, and PET, all of which have excellent moisture-proof properties.

Why Choose EVOH Plastic Sheet

The remarkable feature of EVOH high barrier plastic sheet is its excellent barrier performance to gas. In addition, it also has excellent transparency, gloss, mechanical strength, stretchability, abrasion resistance, cold resistance and surface strength. In the field of packaging, EVOH is made into a composite sheet intermediate barrier layer for all rigid and flexible packaging.

Application of EVOH plastic sheet

The EVOH high barrier film under pp evoh multi-layer barrier sheet extrusion line is mainly used for modified atmosphere preservation. Such as fruit packaging, cooked food, fresh meat, dairy products, condiments, etc. Also used for packaging of non-food items such as chemicals and electronic components.

It is widely used in the packaging of jelly, high-grade meat products, instant rice, medicine, cosmetics, and other industries.

Parameter

| Product Name | High barrier packaging films |

| Material | PA/PE; PA/EVOH/PE; PA/PP |

| Production Technology | Water quenched technology |

| Color | Transparent or Printing |

| Quality Standard | Food Grade; Medical Grade; SGS; FDA |

| Size | Thickness: 55um-300um

Width: 100mm-1200mm |

| Features | 1) Excellent barrier properties of Oxygen and Moisture. 2) Leakage Resistant and High Moisture Proof. 3) High puncture and tear resistance.4) Easy open top film can be produced |

| Application | It can adopt vacuum automatic packaging thermoforming machine, used for meat, sausage, bacon, beef, cheese, egg packaging |

| Others | Packaging: Roll in carton or Customer requirements. |

Application

Client

About Gwell

Innovation drives enterprise progress. Relying on the group’s strong technology, equipment strength and innovation spirit, Gwell is committed to the development of high-tech products and the international market. Gwell also actively exchanges and cooperates with world-class scientific research institutions. The new technologies, new processes and new products developed by Gwell are widely used in building materials(PP hollow sheet extrusion machine, PC optic extrusion machine), home appliances(SPC floor extrusion machine), packaging(PET sheet extrusion machine, EVOH film extrusion machine),

medical treatment(PVC rigid sheet extrusion machine), automobiles(TPU film extrusion machine, PVB film extrusion machine), new energy(EVA solar film extrusion machine), aerospace(TPU film extrusion machine), rail transit(waterproof film extrusion machine) and other fields, which are closely related to human life.

Related Product

The main components of the PC Sheet extrusion production line are selected from the world’s high-quality products (such as screws, barrels, rollers, etc.), and its production process is comprehensive. As an excellent supplier of plastic extruders, GWELL’s complete set of production line has approached the world’s high-quality product standards.

As a premier Chinese manufacturer of plastic extrusion machinery, GWELL delivers cutting-edge PS (Polystyrene) Sheet Extrusion Lines engineered for precision, efficiency, and unmatched product consistency. Our advanced extrusion systems are designed to meet the rigorous demands of diverse industries, offering tailored solutions for high-quality PS sheet production.

As a pioneer in PVB interlayer film production machine technology, we specialize in delivering cutting-edge systems designed for high-performance PVB interlayer film manufacturing. Our PVB interlayer film production machines are engineered to meet global industry standards, combining precision, efficiency, and sustainability.

FAQ

What is the main business of GWELL?

Can I go on a field trip to the GWELL factory?

What are the services for purchasing equipment at GWELL?

What types of plastic extrusion machines are available from GWELL?

What is APET PETG CPET Sheet Extrusion Line?

Where does GWELL ship from?

Are there any technical supports for extrusion machine that you need?

Our service will be always at your disposal over the entire extrusion line life.So if you want to know about any other technical supports.Please contact us as soon as possible.

Previous