PP PC PE Hollow Sheet Extrusion Line

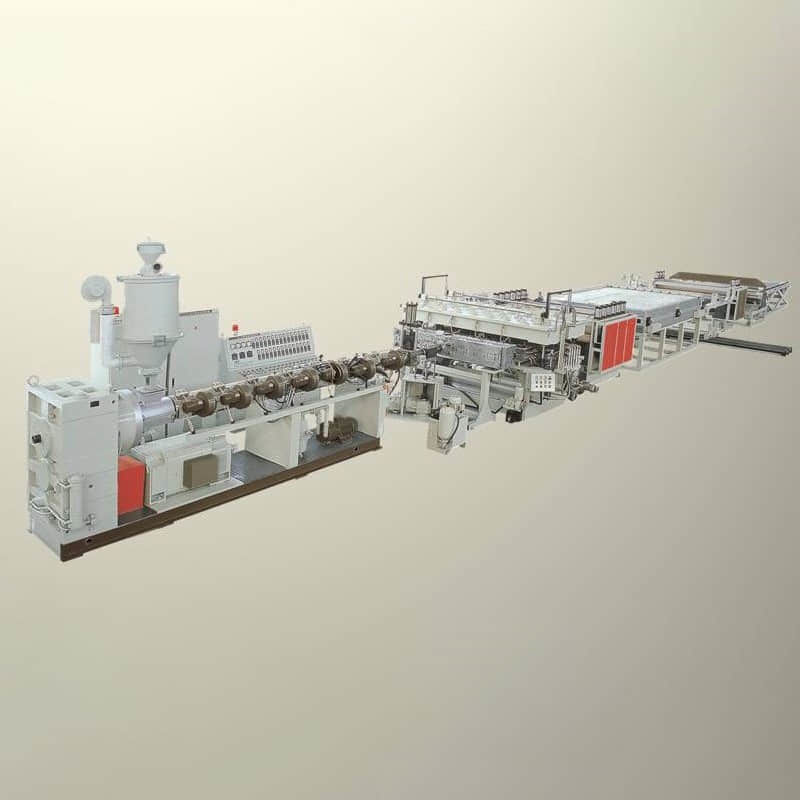

China GWELL PP PC PE hollow sheet extrusion line adopts a specially designed screw extruder and temperature control system to ensure stable plasticizing performance and extrusion efficiency. It has inserted the latest intelligent technology into its PLC program, which can guarantee a more stable, accurate and automated production line. Less labor and high output.

Key words:Sheet Extrusion Line

Category:

Hollow Extrusion Line

Download:

Description

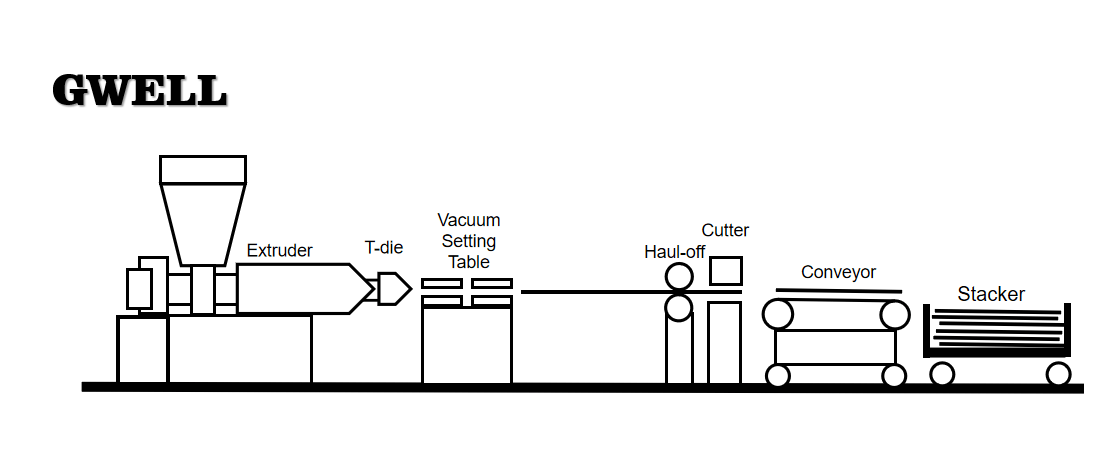

PP PC PE Hollow Sheet Extrusion Line Process Flows

PP PC PE Hollow Sheet Extruder —– T-die —— Calender —- Haul-off —-Cutter —-Conveyor —- Stacker

As a PP Hollow Board Extrusion Line manufacturer, China GWELL uses different screw designs and mechanical configurations to produce PC and PP hollow sheets of various specifications.

Fully automatic PC hollow sheet extrusion line with high capacity. It has inserted the latest intelligent technology into its PLC program, which can guarantee a more stable, accurate and automated production line. Less labor and high output.

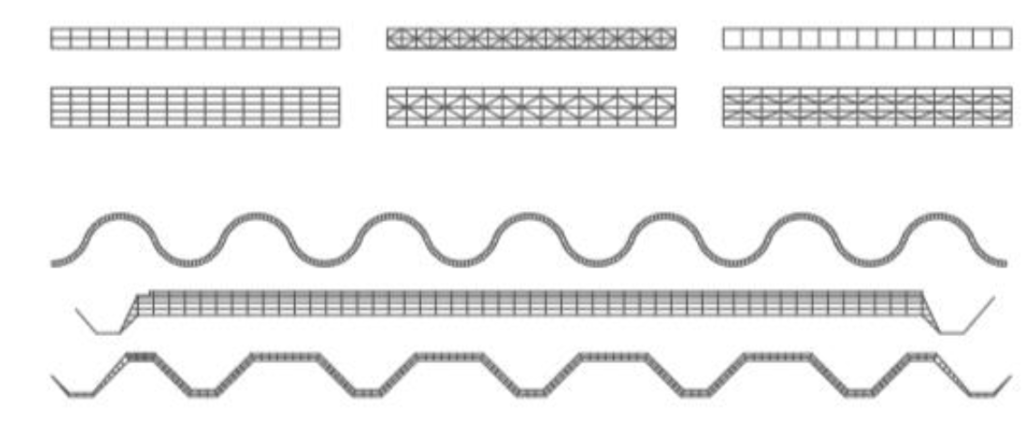

Type of the PC / PP / PE sheet

The specially designed screw structure is suitable for the extrusion of PC / PP / PE recycled materials. It has a width of 1220-2300mm, high output, and good molding. It is a mature model for the production of hollow lattice plates in China.

The flat plate series has such structures as mouth type two-layer sunlight plate 4-10mm, meter type three-layer sunlight plate 10-16mm, Tianzi type three-layer sunlight plate 6-16mm, rectangular four-layer sunlight plate 8-20mm, honeycomb four-layer sunlight plate 8-12mm, diamond seven-layer structure sunlight plate 25-40mm, etc.

The U-shaped structural plate series has a two-layer rectangular structural locking plate of 6-10mm, a four-layer rectangular structural locking plate of 8-12mm, a five-layer meter-shaped structural locking plate of 14-20mm, a seven-layer rectangular structural locking plate of 22-30mm, and other structures.

Unlike the pvc soft sheet extrusion line, the polycarbonate U-lock sheet is an advanced building system with a proven design. It combines excellent daylighting, thermal insulation and high strength. It offers a lightweight, non-thermal expansion and leak-proof design that can withstand very high loads. The many problems with U-shaped systems make them ideal for long-term use in a variety of projects.

PP PC PE Hollow Sheet Extrusion Line Feature

- Extruder: The unique design of the screw and advanced temperature control system ensures a good plasticizing effect of raw materials and stable extrusion with high output.

- Screen changer: Hydraulic quick screen changer is used to make the screen-changing process fast and effective. The double station and special sealing structure ensure the stable operation of the screen changer.

- Mold: PC hollow sheet extrusion line mold is made of high-quality alloy steel, with a highly portable throttling device, so that the distribution pressure of the raw material flow in the mold is uniform, and the upper and lower molds are differentially adjusted to ensure uniform thickness of the upper wall and lower wall. wall.

- Vacuum forming table: PC hollow sheet extrusion line forming system is equipped with a rapid heat exchange refrigeration system. And the vacuum system is effectively staggered, and the suction distribution is even and reasonable. China GWELL hollow board equipment, this distribution ensures the forming accuracy. The vacuum system consists of two subsystems. Each subsystem is equipped with multiple three-point canned cycle vacuum groups. Each fixed cycle is equipped with a vacuum adjustment system and a vacuum display system so that the vacuum degree of the board surface is uniform and stable.

- Tractors: Tractors are divided into the first group and the second group. The first group of tractors are of high power, large reduction ratio and multi-roller type. With excellent low-speed rotation performance and considerable traction, it can pull the sheet out of the vacuum setting table evenly at the same time. The second set of tractors cooperates to relieve product stress. It is also equipped with a trimming device and PVC hollow board equipment to ensure the effective width and edge quality of the board.

- Stress reliever: China PC hollow sheet extrusion line’s advanced large-area conduction heating method can effectively eliminate sheet stress and further improve the flatness of the container.

- Cutting machine: Equipped with precise real-time fixed-length cutting and automatic lifting and unloading devices and special alloy wear-resistant blades to ensure the quality of the cutting surface of the plate. Use sawing for thicker plates over 5mm.

The PC hollow sheet extrusion line is a highly advanced machine that is designed to produce high-quality PC hollow sheets. This product description will introduce the attributes, functions, and advantages of the PC hollow sheet extrusion line.

One of the key features of the PC hollow sheet extrusion line is its high efficiency. It is equipped with an advanced production system that ensures fast and seamless production, thereby enhancing productivity and reducing production time. Additionally, the machine is designed to minimize waste, which translates into lower production costs and increased profitability for clients.

it is also designed with versatility in mind. It can handle a wide range of materials, including polycarbonate (PC), making it an ideal option for clients looking to produce a variety of products. The machine is also built to cater to various production capacities, with options ranging from small-scale to large-scale production.

Another significant advantage of the PC hollow sheet extrusion line is its exceptional quality. It produces PC hollow sheets that meet international standards for impact resistance, heat insulation, and other critical parameters. This makes it an ideal option for clients looking to produce high-quality sheets that offer superior protection against external factors.

The PC hollow sheet extrusion line is also designed with user-friendliness in mind. It comes equipped with an intuitive control system that makes it easy to operate, even for those with minimal technical expertise. The machine is also designed to be low maintenance, with minimal requirements for upkeep, which further reduces costs for clients.

In addition to its impressive performance and reliability, the PC hollow sheet extrusion line is also designed with safety in mind. It comes equipped with various safety features, including an emergency stop button, automatic shutdown function, and overload protection system, which help to prevent accidents and ensure the safety of operators.

Overall, the PC hollow sheet extrusion line is a top-of-the-line product that delivers exceptional performance, reliability, and user-friendliness. With its advanced technology, versatility, and ease of use, it is an ideal option for those in the construction industry looking to produce high-quality PC hollow sheets that meet the specific needs of their clients while minimizing their impact on the environment.”

PC hollow sheet extrusion line application

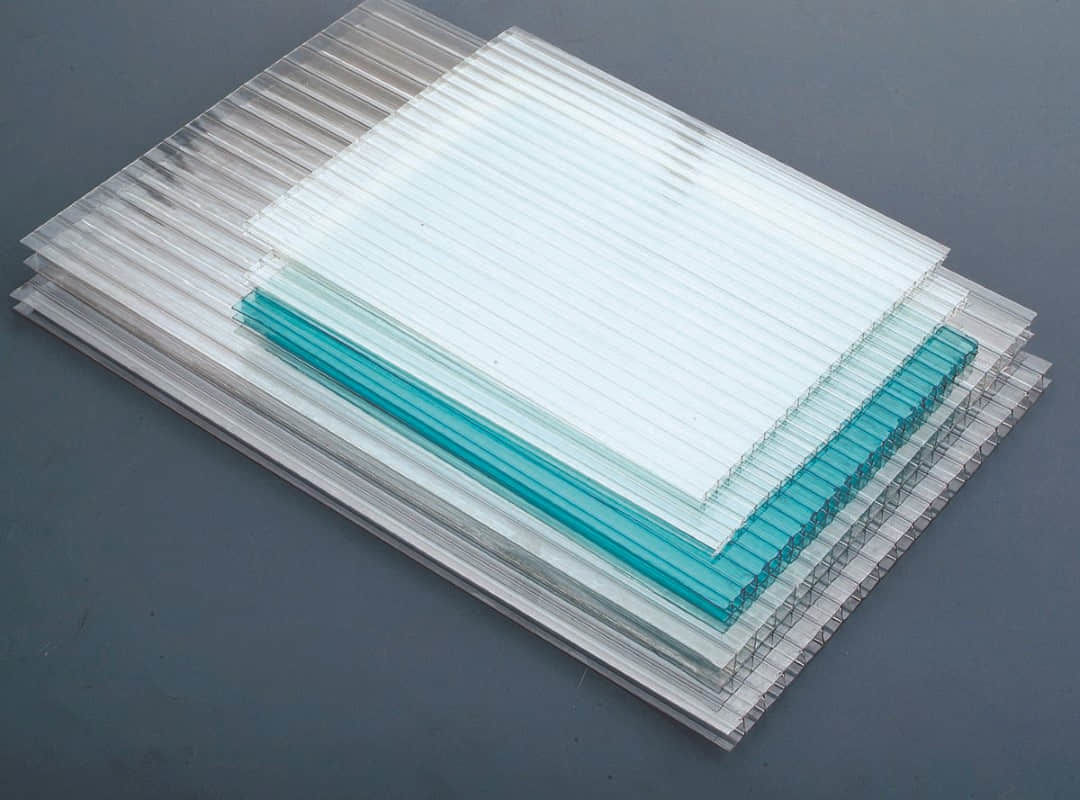

PC hollow sheet extrusion line is made of high-performance engineering plastics—-polycarbonate (PC) resin, which has the characteristics of high transparency, lightweight, impact resistance, sound insulation, heat insulation, flame retardant, anti-aging, etc., is a kind of high-tech, excellent comprehensive performance, energy-saving, and environment-friendly plastic sheet.

PP, PE hollow board is a new type of material with lightweight (hollow structure), non-toxic, non-polluting, waterproof, anti-demand, anti-aging, corrosion resistant and rich colors. Compared with dry cardboard products, hollow boards have the advantages of moisture resistance and corrosion resistance.

PP lattice board application: Hollow Extrusion Line can be processed into turnover boxes, packaging boxes, etc. because of its light weight, high strength, moisture resistance, good environmental performance, and secondary processing performance.

China PC hollow sheet extrusion line is widely used in dry shops, factories, stadiums, lighting canopies and sunshades, agriculture, greenhouses, breeding, and flower greenhouses, as well as telephone booths, newsstands, stations and other public facilities, highway sound insulation, advertising decoration field.

Parameter

| Extruder Type | Single screw extruder GWS120 | Single screw extruder GWS120/GWS65 | Parallel twin screw extruder GWP75 |

| Product Structure | Single layer A | A; A/B/A | Single layer A |

| Raw Material | PP, PE | PC | PC, PP, PE |

| Net Width | 1220mm-2100mm | 1300mm-2100mm | 1220mm-2100mm |

| Thickness range | 2mm-8mm | 4mm-40mm | 2mm-40mm |

| Capacity | 180kg/h-350kg/h | 250kg/h-450kg/h | 200kg/h-450kg/h |

| Application | packing box,Daylighting roof of office buildings, halls, shopping malls, stadiums and public facilities,Canopy of station, parking lot, pavilion, lounge corridor,Noise barriers for expressways and urban viaducts | ||

Application

PC hollow sheet extrusion line application

China PC hollow sheet extrusion line is made of high-performance engineering plastics—-polycarbonate (PC) resin, which has the characteristics of high transparency, lightweight, impact resistance, sound insulation, heat insulation, flame retardant, anti-aging, etc. , is a kind of high-tech, excellent comprehensive performance, energy-saving and environment-friendly plastic sheet.

PP, PE hollow board is a new type of material with lightweight (hollow structure), non-toxic, non-polluting, waterproof, anti-demand, anti-aging, corrosion resistant, and rich colors. Compared with dry cardboard products, hollow boards have the advantages of moisture resistance and corrosion resistance.

PP lattice board application: PP hollow lattice board can be processed into turnover boxes, packaging boxes, etc. because of its lightweight, high strength, moisture resistance, good environmental performance, and secondary processing performance.

- Daylighting roofs of office buildings, halls, shopping malls, stadiums, and public facilities

- Canopy of the station, parking lot, pavilion, lounge corridor

- Noise barriers for expressways and urban viaducts

PP PE hollow sheet extrusion line application:

PP PE hollow sheet extrusion line can be processed into a turnover box and packing box because of its light material, high strength, moisture-proof, good environmental protection performance, and secondary processing performance.

Client

About Gwell

Innovation drives enterprise progress. Relying on the group’s strong technology, equipment strength and innovation spirit, Gwell is committed to the development of high-tech products and the international market. Gwell also actively exchanges and cooperates with world-class scientific research institutions. The new technologies, new processes and new products developed by Gwell are widely used in building materials(PP hollow sheet extrusion machine, PC optic extrusion machine), home appliances(SPC floor extrusion machine), packaging(PET sheet extrusion machine, EVOH film extrusion machine),

medical treatment(PVC rigid sheet extrusion machine), automobiles(TPU film extrusion machine, PVB film extrusion machine), new energy(EVA solar film extrusion machine), aerospace(TPU film extrusion machine), rail transit(waterproof film extrusion machine) and other fields, which are closely related to human life.

Related Product

The main components of the PC Sheet extrusion production line are selected from the world’s high-quality products (such as screws, barrels, rollers, etc.), and its production process is comprehensive. As an excellent supplier of plastic extruders, GWELL’s complete set of production line has approached the world’s high-quality product standards.

As a premier Chinese manufacturer of plastic extrusion machinery, GWELL delivers cutting-edge PS (Polystyrene) Sheet Extrusion Lines engineered for precision, efficiency, and unmatched product consistency. Our advanced extrusion systems are designed to meet the rigorous demands of diverse industries, offering tailored solutions for high-quality PS sheet production.

As a pioneer in PVB interlayer film production machine technology, we specialize in delivering cutting-edge systems designed for high-performance PVB interlayer film manufacturing. Our PVB interlayer film production machines are engineered to meet global industry standards, combining precision, efficiency, and sustainability.

FAQ

What is the main business of GWELL?

Can I go on a field trip to the GWELL factory?

What are the services for purchasing equipment at GWELL?

What types of plastic extrusion machines are available from GWELL?

What is APET PETG CPET Sheet Extrusion Line?

Where does GWELL ship from?

Are there any technical supports for extrusion machine that you need?

Our service will be always at your disposal over the entire extrusion line life.So if you want to know about any other technical supports.Please contact us as soon as possible.

Previous

上一页