SPC LVT Board Extrusion Line

China GWELL, as China Plastic Extruder Supplier, SPC LVT Board Extrusion Line is produced by conical twin-screw extruder, through three or four roll calenders, one-time compounding of PVC color film, PVC wear-resistant layer, and PVC substrate.

Key words:Sheet Extrusion Line

Category:

Floor Extrusion line

Download:

Description

China GWELL SPC LVT flooring extrusion line Features

GWELL as China Plastic Extruder manufacturer, SPC LVT floor extrusion line is produced by the conical twin-screw extruder, through three or four roll calender, laminating PVC color film, PVC wear-resistant layer, and PVC substrate at one time.

The process is simple, easy to operate, the lamination is completed by heat and no glue is needed. SPC LVT stone plastic floor is based on high-tech development of a new type of environmental protection floor, with zero formaldehyde, mold, moisture, fire, insect prevention, simple installation, and other characteristics.

SPC LVT floor material uses environmental protection formula, and it does not contain heavy metals, phthalates, formaldehyde, and other harmful substances.

In Europe, the United States, and the Asia-pacific market, it is widely popular. With its outstanding stability and durability, the stone plastic floor has solved the problem of a real wood floor being affected by damp, deformation, and mildew, and solved the formaldehyde problem of other decoration materials. It can choose any design and color patterns, suitable for indoor decoration, hotels, hospitals, shopping malls, and other public places.

SPC LVT Board Extrusion Line Process Flows

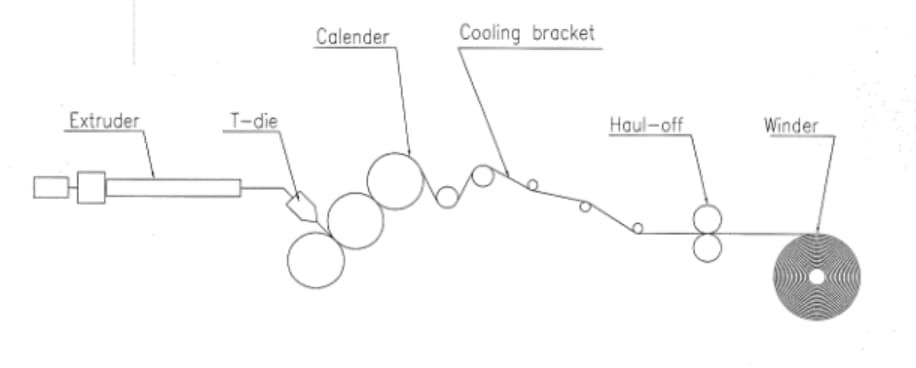

Extruder —- Screen changer —–Melt pump —– T-die —— Calender —– Cooling bracket —– Haul-off—- winder

Advantages of SPC LVT floor produced by GWELL in China

- Waterproof and moisture-proof. The basic solution to the moisture and water absorption of wood products in the environment is easy to rot, expansion and deformation, and it can be used in an environment in which traditional wood products can not be used.

- Anti-insect, anti-termite, effectively eliminate insect harassment, extend the service life.

- It is colorful and has many colors to choose from. It has a natural wood texture and wooden pattern, and it can be customized the color according to customers’ requirements.

- Strong plasticity. It can be very simple to achieve personalized modeling and fully reflect the personality style.

- High environmental protection, pollution-free, and recyclable. The product does not contain benzene and formaldehyde. Recycled products greatly save the amount of wood, so it is suitable for sustainable development of the national policy, and benefit the society.

- High fire resistance. Effective flame retardant, fireproof class B1, self-extinguishing in case of fire, and do not produce any toxic gas.

- Good processability, can be ordered, planed, sawed, drill, the surface can be painted.

- Simple installation, convenient construction, do not need complex construction process, save installation time and cost.

SPC LVT floor extrusion line process

- Mixing: according to the formulation, the raw materials are poured into the high-speed mixer for hot mixing (hot mixing temperature: 125 ℃, the function is to mix all kinds of materials uniformly, remove the water in the material), then it enters into the cold mixer (to cool the material to prevent Agglomeration and discoloration, cold mixing temperature: 55℃.) to cool and mix materials uniformly;

- Extrusion:GWELL as China Plastic Extruder manufacturer,feed the mixed material into the conical twin-screw extruder for heating and extrusion, and then it enters into the T-die for molding. The formed sheet is passed through a four-roller calendar. After the base material is shaped, it will be laminated with a decorative film, wear-resistant layer, and then the whole piece of SPC LVT floor will be cooed again and finally be cut into required length;

- UV tempering: the SPC LVT floorboard will be coated with one layer of UV layer and then tempered(tempering hot water temperature: 80~120℃; cold water temperature: 10℃) to make them combined well;

Parameter

| Type of extruder | Conical twin-screw extruder GWC80/156 | Conical twin-screw extruder GWC92/188 | Conical twin-screw extruder GWC92/188+conical twin-screw extruder GWC80/156 |

| Structure of product | Single layer | Single layer | Three-layer, A/B/A |

| Net Width | 1000mm | 1000mm | 1000mm |

| Thickness range | 2mm-5mm | 2mm-5mm | 2mm-5mm |

| Capacity | 350kg/h-400kg/h | 600kg/h-750kg/h | 850kg/h-1100kg/h |

Application

Mainly used for producing the sort of PVC Floor leather rolls.

PVC Floor leather has the function of anti-friction, corrosion resistance, skidproof, impermeable, and inflaming retarding, and is widely used on auto, hotel, amusement place, exhibition hall, house, etc. The structure of this production line is simple, and convenient to operate.

According to customers’ requirements, equipped with different components, used for producing single layer,multi-layer composite production and also can be equipped with unreeling unit, used for producing inner strengthen production or surface compound non-woven fabrics and PVC decoration film, etc.

Client

About Gwell

Innovation drives enterprise progress. Relying on the group’s strong technology, equipment strength and innovation spirit, Gwell is committed to the development of high-tech products and the international market. Gwell also actively exchanges and cooperates with world-class scientific research institutions. The new technologies, new processes and new products developed by Gwell are widely used in building materials(PP hollow sheet extrusion machine, PC optic extrusion machine), home appliances(SPC floor extrusion machine), packaging(PET sheet extrusion machine, EVOH film extrusion machine),

medical treatment(PVC rigid sheet extrusion machine), automobiles(TPU film extrusion machine, PVB film extrusion machine), new energy(EVA solar film extrusion machine), aerospace(TPU film extrusion machine), rail transit(waterproof film extrusion machine) and other fields, which are closely related to human life.

Related Product

The main components of the PC Sheet extrusion production line are selected from the world’s high-quality products (such as screws, barrels, rollers, etc.), and its production process is comprehensive. As an excellent supplier of plastic extruders, GWELL’s complete set of production line has approached the world’s high-quality product standards.

As a premier Chinese manufacturer of plastic extrusion machinery, GWELL delivers cutting-edge PS (Polystyrene) Sheet Extrusion Lines engineered for precision, efficiency, and unmatched product consistency. Our advanced extrusion systems are designed to meet the rigorous demands of diverse industries, offering tailored solutions for high-quality PS sheet production.

As a pioneer in PVB interlayer film production machine technology, we specialize in delivering cutting-edge systems designed for high-performance PVB interlayer film manufacturing. Our PVB interlayer film production machines are engineered to meet global industry standards, combining precision, efficiency, and sustainability.

FAQ

What is the main business of GWELL?

Can I go on a field trip to the GWELL factory?

What are the services for purchasing equipment at GWELL?

What types of plastic extrusion machines are available from GWELL?

What is APET PETG CPET Sheet Extrusion Line?

Where does GWELL ship from?

Are there any technical supports for extrusion machine that you need?

Our service will be always at your disposal over the entire extrusion line life.So if you want to know about any other technical supports.Please contact us as soon as possible.

Previous

下一页