PE Wrap Film Extrusion Line

As China Plastic Extruder Supplier, China GWELL uses multi-layer co-extrusion technology in PE wrap film extrusion line, which can be more flexible and mature in the use of raw materials according to the needs of different customers, and the formula cost is lower.

Key words:Sheet Extrusion Line

Category:

Film Extrusion Line

Download:

Description

Characteristics of PE wrap film extrusion line

- The application of multi-layer co-extrusion technology can be more flexible and mature in using raw materials according to the needs of different customers, and the formula cost is lower.

- The apparent difference from the traditional wrapping film production line is: that a four-axis 90-degree roll change is adopted for roll change, fast speed, no tail material, and quick change time, which means that in high-speed production, it can produce 2KG hand-use Small rolls of stretch film can also be produced in large rolls of machine stretch film. In this way, both 3-inch and 2-inch paper tubes can be produced and used online, reducing the subsequent secondary rewinding process and significantly reducing the rewinder equipment’s investment and labour cost.

PE wrap film extrusion line uses

GWELL as China Plastic Extruder manufacturer, PE wrap film extrusion line stretch film is developed from a single layer to two layers and three layers. Now the stretch film produced by the casting method is mainly used. The early stretch film is mostly blown film. , This is because the production of the casting line has the advantages of uniform thickness and high transparency, which can be applied to the requirements of high-magnification pre-stretching. The stretch film produced by the China GWELL casting method has high clarity, high elongation, high puncture strength, and tear strength.

PE wrap film extrusion line products have a wide range of applications and are widely used in the integrated packaging of hardware, minerals, chemicals, medicine, food, machinery and other products. Casting film has excellent heat-sealing performance and excellent transparency. It is one of the primary packaging composite substrates for producing high-temperature cooking films, vacuum aluminized films, etc.

Characteristics of PE wrap film extrusion line

- GWELL as China Plastic Extruder Supplier adopts multi-layer co-extrusion technology according to customer requirements, which has higher flexibility in material use and lower cost of ingredients.

- The rewinding unit automatically applies the film, and there is no need to stick tape on the core, which effectively saves the cost of video and labor while reducing the time of rewinding and film waste.

- China GWELL is equipped with automatic mould system, SCANTECH thickness gauge and energy-saving motor to ensure low energy consumption and a high degree of automation.

- The feeding section is fitted with an automatic batching unit, and the batching percentage of the batching is highly guaranteed.

- PE wrap film extrusion line can add a longitudinal stretching unit according to customer requirements to produce an ultra-thin pre-stretched stretch film and realize the functions of edge folding and pre-stretching.

- Optional automatic weighing system can reduce labour intensity and improve production efficiency.

PE wrap film extrusion line following advantages

- China GWELL adopts double-layer co-extrusion equipment, and the stretched film after pressing maximizes the characteristics of each polymer, and its transparency, tensile strength, and perforation resistance reach the best state at the melting point.

- It has good tensile properties, good transparency, and uniform thickness.

- It has good longitudinal extensibility, good resilience, good transverse tear resistance, and excellent self-adhesive lapping.

- It is environment-friendly recyclable material, tasteless, non-toxic, and can be directly packaged food.

- It can produce single-sided viscous products, reduce the noise during winding and stretching, and reduce dust and sand during transportation and storage.

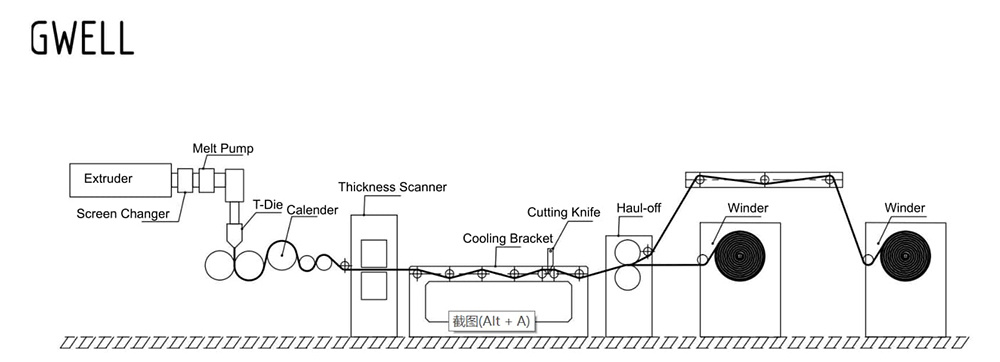

PE wrap film extrusion line Process Flows

Extruder —— Screen changer —— Melt pump —— T-die —— Calender —— Thickness Scanner —— Cooling Bracket —— Cutting Knife —— Haul-off —— Winder

In the early stage, LLDPE stretch film was mostly blown film, which developed from single layer to two and three layers; LLDPE stretch film is mainly produced by tape casting because the tape casting line has the advantages of uniform thickness and high transparency, which can be suitable for the requirements of high magnification pre-stretching.

Because single-layer tape casting can‘t do single-sided adhesion, its application field is limited. Single and double-layer casting is not as wide in material selection as three-layer casting, and the formulation cost is also high, so the three-layer coextrusion structure is ideal.

The high-quality tensile film shall have the characteristics of high transparency, high longitudinal elongation, high yield point, high transverse tear strength, and good puncture performance.

As China Plastic Extruder manufacturer, GWELL adopts imported linear polyethylene LLDPE resin and special additives for tackifiers. It can produce multi-functional stretch film such as hand-use, resistance machine, pre-stretching machine, anti-ultraviolet, anti-static, anti-rust and so on.

Parameter

| Extruder Type | Single screw extruder GWS90 | Single screw extruder GWS120 | Single screw extruder GWS150 | Single screw extruder GWS160 |

| Raw material | LDPE, LLDPE | |||

| Net width | 1500mm | 2200mm | 2800mm | 3200mm |

| Thickness range | 0.02mm-1mm | |||

| weight of product | 15-50g/m2 | |||

| output | 200kg/h | 400kg/h | 550kg/h | 650kg/h |

| Line speed | 200m/min | |||

Application

1. For sealed packaging

This kind of packaging means that the film wraps the tray around the tray, and the films at both ends are heat-sealed together through two hot grasps. This form of packaging is relatively early, and now the utilization rate is not high.

2. For full-width packaging

The requirement of this packaging form is that the film width is enough to cover the tray, and the width of the film is required, with a thickness of about 17 ~ 35 μ m.

3. For manual packaging

This packaging form is the simplest. A film is installed on the shelf and rotated by the tray or around the tray. This kind of packing is mainly applicable to repackaging after the pallet is wrapped and damaged. The packaging speed is relatively slow, and the thickness of the film is required to be 15 ~ 20 μ m.

4. For winding machine packaging

This packaging form belongs to mechanical packaging, which is mainly rotated by the tray or the film around the tray. The film is fixed on the support and can move up and down. The packaging capacity is very strong, about 15 ~ 18 plates per hour.

5. For horizontal mechanical packaging

This kind of packaging means that the film should rotate around the goods, which is more suitable for long goods packaging, such as carpet, plate, fiberboard, special-shaped materials, etc. it is also common in life.

6. Packaging for small items

This is also the latest packaging form. The advantages of this packaging are obvious. It can reduce the consumption of materials and reduce the storage space of pallets. It is especially popular abroad.

7. Packaging for pipes and cables

This kind of packaging requires the packaging equipment to be installed at the end of the production line and fully automatically stretch the film, so that it can replace the tape to bind the materials and play a good protective role.

Client

About Gwell

Innovation drives enterprise progress. Relying on the group’s strong technology, equipment strength and innovation spirit, Gwell is committed to the development of high-tech products and the international market. Gwell also actively exchanges and cooperates with world-class scientific research institutions. The new technologies, new processes and new products developed by Gwell are widely used in building materials(PP hollow sheet extrusion machine, PC optic extrusion machine), home appliances(SPC floor extrusion machine), packaging(PET sheet extrusion machine, EVOH film extrusion machine),

medical treatment(PVC rigid sheet extrusion machine), automobiles(TPU film extrusion machine, PVB film extrusion machine), new energy(EVA solar film extrusion machine), aerospace(TPU film extrusion machine), rail transit(waterproof film extrusion machine) and other fields, which are closely related to human life.

Related Product

The main components of the PC Sheet extrusion production line are selected from the world’s high-quality products (such as screws, barrels, rollers, etc.), and its production process is comprehensive. As an excellent supplier of plastic extruders, GWELL’s complete set of production line has approached the world’s high-quality product standards.

As a premier Chinese manufacturer of plastic extrusion machinery, GWELL delivers cutting-edge PS (Polystyrene) Sheet Extrusion Lines engineered for precision, efficiency, and unmatched product consistency. Our advanced extrusion systems are designed to meet the rigorous demands of diverse industries, offering tailored solutions for high-quality PS sheet production.

As a pioneer in PVB interlayer film production machine technology, we specialize in delivering cutting-edge systems designed for high-performance PVB interlayer film manufacturing. Our PVB interlayer film production machines are engineered to meet global industry standards, combining precision, efficiency, and sustainability.

FAQ

What is the main business of GWELL?

Can I go on a field trip to the GWELL factory?

What are the services for purchasing equipment at GWELL?

What types of plastic extrusion machines are available from GWELL?

What is APET PETG CPET Sheet Extrusion Line?

Where does GWELL ship from?

Are there any technical supports for extrusion machine that you need?

Our service will be always at your disposal over the entire extrusion line life.So if you want to know about any other technical supports.Please contact us as soon as possible.