Stone Paper Extrusion Line

GWELL stone paper extrusion line can produce synthetic paper products with 40% to 80% inorganic powder added. It is composed of raw material conveying and processing system, edge material recovery system, extrusion equipment, casting equipment, longitudinal stretching machine, transverse stretching machine, winding machine, electrical system and automatic film thickness gauge.

Key words:Sheet Extrusion Line

Category:

Stretch film extrusion line

Download:

Description

Stone paper extrusion line refers to a type of production equipment used to produce stone paper and similar products. The main design principle is similar to that of the Film Extrusion Line.

Stone paper extrusion line can produce synthetic paper products with an inorganic powder addition ratio of 40% to 80%. It is composed of raw material conveying treatment system, edge material recovery system, extrusion equipment, casting equipment, longitudinal stretching machine, horizontal stretching machine, winding machine, electrical system, and automatic film thickness gauge.

Stone paper is divided into PP and PE. Users can select materials and papermaking methods according to the purpose of the paper. The processing method of the stone paper extrusion line is divided into salivating stone paper/synthetic paper production line; unidirectional stretching stone paper/synthetic paper production line; and bidirectional stretching stone paper/synthetic paper production line.

Stone Paper Extrusion Line includes

Three parts: material handling (granulation), salivation stretching (papermaking), and coating (paper surface treatment).

China GWELL can provide complete solutions such as plant planning and layout, technical training for stone paper production personnel, stone paper extrusion line, stone paper production process, and formula for all aspects of stone paper production. We have provided many sets of stone paper turnkey projects at home and abroad, and have been widely recognized by customers.

Stone Paper Extrusion Line Process Flows

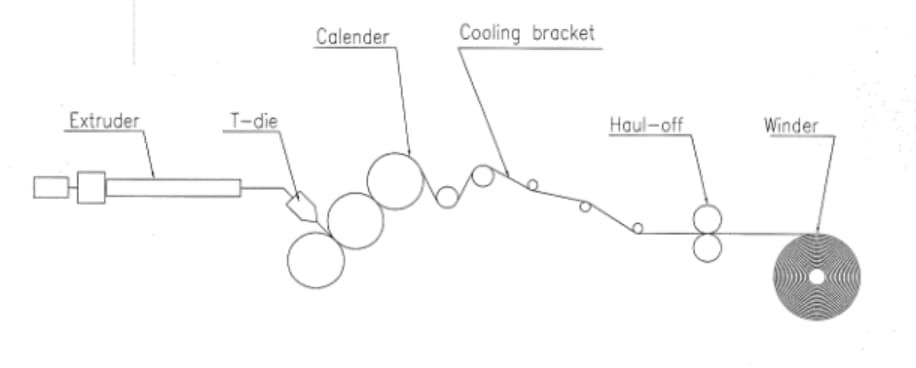

Extruder —- Screen changer —– Melt pump —– T-die —— Calender —– Cooling bracket —– Haul-off—- Winder

Composition and process of stone paper extrusion line

The stone paper extrusion line is mainly composed of five parts: extrusion part, casting part, corona part, winding part and electric control part. Among them, the mold part and the extrusion part can be freely combined according to the requirements of users, so as to meet the different needs of our customers (markets) to the greatest extent.

The special masterbatch is produced by batching, blending and extrusion of the stone paper machine, and then through extrusion, calendering, stretching, cooling, surface treatment, coating, slitting and winding, it is the base paper. High production efficiency, good product quality, low production cost, smooth paper surface, especially suitable for printing albums and book covers, etc.

Introduction of stone paper products

The stone paper of the stone paper extrusion production line is a new type of material between paper and plastic, which can not only replace some traditional functional paper and professional paper, but also replace most of the traditional plastic packaging. In addition, it has the characteristics of low cost and controllable degradation, which can save users a lot of cost without causing pollution. In the Film Extrusion Line, the new environmentally friendly material stone paper industry has a wide variety of materials, product upgrades, technology upgrades, and wide application fields. It is a sunrise industry with strong vitality.

Composition and process of stone paper extrusion line

The stone paper extrusion line is mainly composed of five parts: extrusion part, casting part, corona part, winding part and electric control part. Among them, the mold part and the extrusion part can be freely combined according to the requirements of users, so as to meet the different needs of our customers (markets) to the greatest extent.

The special masterbatch is produced by batching, blending and extrusion of the stone paper machine, and then through extrusion, calendering, stretching, cooling, surface treatment, coating, slitting and winding, it is the base paper. High production efficiency, good product quality, low production cost, smooth paper surface, especially suitable for printing albums and book covers, etc.

Stone paper extrusion line product features

- The stone paper production process of the stone paper extrusion line is simple, with high output and low energy consumption.

- It does not use plant fibers and does not cut down trees, which can save a lot of wood and protect the natural ecology.

- There is no need to add chemical raw materials such as strong acid, strong alkali, bleaching agent, and no waste water, waste residue and harmful gases are discharged. It is a green product.

- China GWELL stone paper extrusion line products have good mechanical properties, waterproof, moisture-proof, moth-proof, folding resistance, tear resistance, oil resistance, no, odorless, no pollution, stable geometric dimensions, high printing definition, good effect, and can be used After being discarded, it can be naturally degraded into powder and return to nature.

- Widely used in gift packaging, pharmaceutical packaging, office supplies, decorative albums and other printed products.

Features of stone paper extrusion line

- It has no grains. Traditional equipment needs to granulate in advance and then produce products, while Stone Paper Extrusion Line uses multi-component high-precision scales to produce stone paper.

- Screw with special mixing function and BM design.

- The screen changer can filter the no-need material, and the melt pump can provide stable pressure to reach the objective of even thickness.

- T-die adopts a special design to make plate thickness adjustment more accurate.

- A three-roll calendar adopts a 45-degree tilt type, which can be raised or lowered freely.

- Stone paper thickness control adopts screw adjustment and press wheel two-way adjustment to control plate thickness.

- Gwell adopts an automatic winder to reduce the manual. and has made heroic efforts at cost reduction.

Advantages and characteristics of stone paper

- Save resources: No wood or natural plant fiber is needed, and no large amount of water is used in production, especially in Iran. Because this country the wood resource is a shortage.

- Environmental protection is outstanding: no discharge of wastewater, waste residue, or waste gas, and the leftovers in production can be automatically recycled and recycled again or naturally degraded after processing.

The stone paper extrusion line is a revolutionary product that is designed to cater to the needs of the paper industry. This machine is built with advanced technology and precision to deliver high-quality results and meet the specific needs of clients. In this product description, we will introduce the attributes, functions, and advantages of the stone paper extrusion line.

One of the key features of the stone paper extrusion line is its ability to produce paper from stone. This is achieved by using calcium carbonate, which is a natural mineral found in abundance in the earth’s crust, as the primary raw material. This makes the stone paper extrusion line an eco-friendly option that helps to conserve natural resources and reduce the carbon footprint of the paper industry.

The stone paper extrusion line is also designed with versatility in mind. It can handle a wide range of materials, including PVC, PE, and PP, making it an ideal option for diverse industries. Additionally, the machine comes equipped with an automatic control system that allows for easy and straightforward operation, even for beginners.

Another significant advantage of the stone paper extrusion line is its exceptional efficiency. It features a high-speed motor that ensures fast and seamless operation, thereby enhancing productivity and reducing production time. The machine is also designed to minimize waste, which translates into lower production costs and increased profitability for clients.

One of the key selling points of the stone paper extrusion line is its durability. It is built with high-quality materials that are resistant to wear and tear, making it a long-lasting and reliable investment. The machine is also easy to maintain, with minimal requirements for upkeep, which further reduces costs for clients.

In addition to its impressive performance and reliability, the stone paper extrusion line is also designed with safety in mind. It comes equipped with various safety features, including an emergency stop button, automatic shutdown function, and overload protection system, which help to prevent accidents and ensure the safety of operators.

The stone paper extrusion line is also an eco-friendly option that helps to reduce the environmental impact of the paper industry. The production of paper from stone results in lower carbon emissions, reduced water consumption, and less waste. Additionally, the use of natural minerals as the primary raw material reduces the need for deforestation, which helps to preserve natural habitats and biodiversity.

GWELL a China Plastic Extruder Supplier, stone paper extrusion line product stone paper contributes to the environment, stone paper is a large amount of inorganic mineral powder completely dissolved in a small amount of non-toxic resin, the process is environmentally friendly, and it can be brittle and return to the earth after use. If the recycled paper is sent to the incinerator for incineration, a small amount of non-toxic and harmless resin will not produce black smoke or poisonous gas after incineration, and the remaining inorganic mineral powder can also return to the earth and nature.

Parameter

| Extruder type | Single screw stone paper extrusion line GWS | Parallel twin-screw stone paper extrusion line GWP | Conical twin-screw stone paper extrusion line GWCP |

| Raw material | PP, PE, CaCo3 | ||

| Stretching methods | MDO longitudinal stretch unit | ||

| Structure of product | A; A/B; A/B/A | ||

| Stretch ratio | 2-20 times; 3-30 times; 5-50 times | ||

| Max linear speed | 100m/min | ||

| Application | Dust covers, Protective covers of electronic, Household appliances, Shopping bags, Garbage bags, Even roll bags, and etc. | ||

Application

China Plastic Extruder manufacturer stone paper is mainly used to replace traditional plastic packaging products and environment.

Industrial packaging: dust covers and protective covers of electronic, household appliances, and industrial equipment products ;

Life packaging materials: daily use packaging bags, shopping bags, garbage bags, and even roll bags, etc.

Decorative wallpaper, cartons, cartons, coated paper, paper, labels, cards, advertising decoration paper, postal paper; paper use, such as field work paper, underwater work paper, mining work paper, paper, etc.

With the continuous maturity and upgrading of stone papermaking technology, the application field continues to expand. The cost of stone paper products is 20%-30% lower than that of alternative paper products. They have strong competitiveness and promising market prospects.

If you want to know more about stone paper extrusion line, you can check this article: What is Stone Paper Machine used for?

Client

About Gwell

Innovation drives enterprise progress. Relying on the group’s strong technology, equipment strength and innovation spirit, Gwell is committed to the development of high-tech products and the international market. Gwell also actively exchanges and cooperates with world-class scientific research institutions. The new technologies, new processes and new products developed by Gwell are widely used in building materials(PP hollow sheet extrusion machine, PC optic extrusion machine), home appliances(SPC floor extrusion machine), packaging(PET sheet extrusion machine, EVOH film extrusion machine),

medical treatment(PVC rigid sheet extrusion machine), automobiles(TPU film extrusion machine, PVB film extrusion machine), new energy(EVA solar film extrusion machine), aerospace(TPU film extrusion machine), rail transit(waterproof film extrusion machine) and other fields, which are closely related to human life.

Related Product

The main components of the PC Sheet extrusion production line are selected from the world’s high-quality products (such as screws, barrels, rollers, etc.), and its production process is comprehensive. As an excellent supplier of plastic extruders, GWELL’s complete set of production line has approached the world’s high-quality product standards.

As a premier Chinese manufacturer of plastic extrusion machinery, GWELL delivers cutting-edge PS (Polystyrene) Sheet Extrusion Lines engineered for precision, efficiency, and unmatched product consistency. Our advanced extrusion systems are designed to meet the rigorous demands of diverse industries, offering tailored solutions for high-quality PS sheet production.

As a pioneer in PVB interlayer film production machine technology, we specialize in delivering cutting-edge systems designed for high-performance PVB interlayer film manufacturing. Our PVB interlayer film production machines are engineered to meet global industry standards, combining precision, efficiency, and sustainability.

FAQ

What is the main business of GWELL?

Can I go on a field trip to the GWELL factory?

What are the services for purchasing equipment at GWELL?

What types of plastic extrusion machines are available from GWELL?

What is APET PETG CPET Sheet Extrusion Line?

Where does GWELL ship from?

Are there any technical supports for extrusion machine that you need?

Our service will be always at your disposal over the entire extrusion line life.So if you want to know about any other technical supports.Please contact us as soon as possible.

Previous

上一页