PVC Floor Leather Extrusion Line

As China Plastic Extruder Supplier, China GWELL PVC Floor Leather Extrusion Line can be equipped with different components for single-layer and multi-layer composite production according to customer requirements. It can also be equipped with an unwinding device for the production of inner reinforced production or surface composite non-woven fabrics, PVC decorative films, etc.

Key words:Sheet Extrusion Line

Category:

Floor Extrusion line

Download:

Description

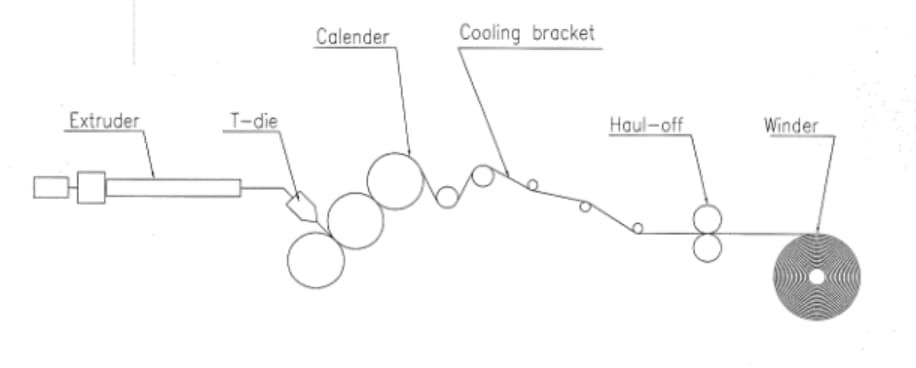

PVC Floor Leather Extrusion Line Process Flows

Extruder —- Screen changer —–Melt pump —– T-die —— Calender —– Cooling bracket —– Haul-off—- winder

PVC Floor Leather Extrusion Line is also known as PVC soft floor mat equipment, PVC embossed floor mat equipment, and different names are used in different regions. PVC floor leather equipment is used differently due to different formulations, processes, and surface treatments in the later stage. In the general market, such products will also be very different. Basements, underground garages, tool rooms, toilets, etc., are made of single-layer or multi-layer PVC products, with embossed surfaces but no PVC wood grain film on the surface. This is the so-called PVC soft floor mat, PVC embossed floor mat. Hotels, guesthouses, pavilions, homes, etc., use excellent PVC films on the surface. This PVC film is a heat cladding process in the production process; this PVC film has a variety of patterns to prevent wood grain.

China GWELL PVC Floor Leather Extrusion Line is mainly used to produce PVC floor leather products. PVC Floor leather has the properties of wear resistance, corrosion resistance, anti-skid, anti-seepage, and flame retardant. It is widely used in locomotives, hotels, hotels, halls, exhibition halls, and families. According to customer requirements, different equipment components can be configured for the production of single-layer and multi-layer composite products; unwinding devices can also be added to produce products with internal reinforcement or surface composite non-woven fabrics, PVC decorative films, etc.

The PVC floor leather production line provided by China GWELL can be specially designed according to customer needs, providing customers with customized equipment to meet different production needs of customers. The equipment can add or subtract different parts to achieve the function of producing different products.

- China GWELL PVC floor leather equipment, PVC soft floor mat equipment, and PVC embossed floor mat equipment can be equipped with different equipment parts according to different requirements and can produce single-layer, multi-layer, lamination, protective film, etc.

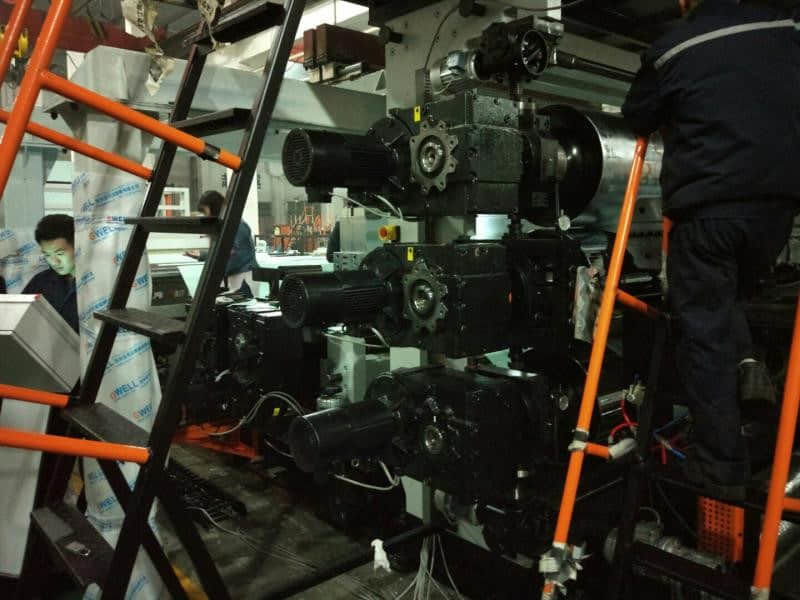

- GWELL as China Plastic Extruder manufacturer, the extruder adopts conical twin-screw extruder, and the extrusion output is different according to the width of the product.

- Screw hardness of different directions of outward rotation: cylinder HV > 940hv, screw hardness > 740. 38crmoaia nitriding and distribution box reducer absorb Italian technology and adopt hard-tooth surface helical gear grinding technology.

- The material of the reduction gear is 0crmnti, carburized, ground, and quenched, the hardness is HRC58-62 degrees, and the gear is ground. Unit coupling structure, stable operation.

- Imported thrust bearing, high torque output.

- The PVC floor leather equipment, PVC soft floor mat equipment, PVC embossed floor mat equipment, and electrical appliances adopt Siemens touch screen and ABB frequency converter. Through multi-window data acquisition, human-computer interaction is realized, and the PLC control system is controlled with high precision.

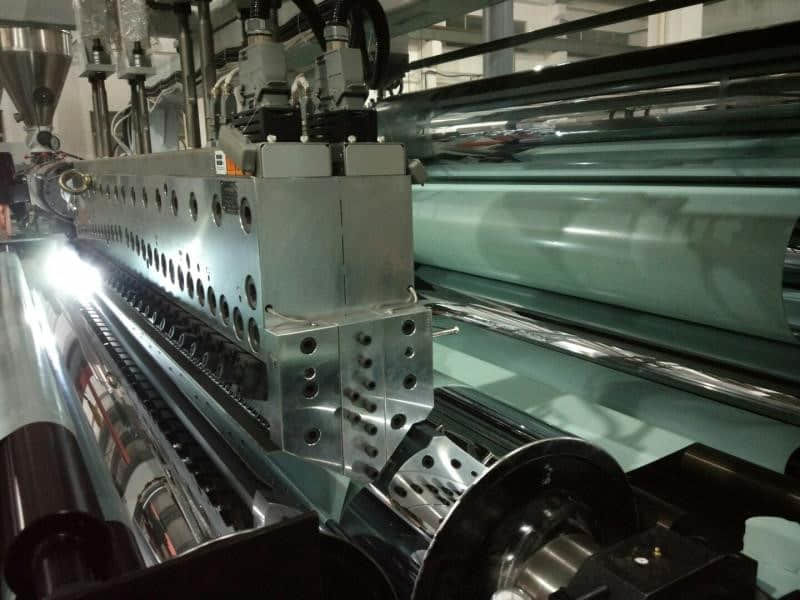

- China GWELL adopts high-precision temperature measurement and control equipment, which can ensure the barrel temperature. Each heating section can be displayed through the touch screen. The product is subjected to die extrusion, thickness adjustment of three-roll calender, cooling bracket cooling, double-station crimping machine, automatic cutting machine, and precise length control.

Advantages of PVC floor leather:

- The price is several times higher than that of wooden floors, but there are many laminate floors in the market, and the price is quite the same as it.

- Because it is waterproof and water-resistant, it can be scrubbed with water.

- Various patterns can be purchased according to your preferences and can be replaced once every two or three years.

- Easy to use, time-saving and labor-saving

Features of China GWELL PVC floor leather extrusion line

- Screw with special mixing function and high plasticizing capacity design.

- Screen changer can filter the no-need material, and melt pump can provide the

- stable pressure to reach the objective of uniform thickness.

- hanger die head adopts a special design to make plate thickness adjustment more accurate.

- temperature control ±1C can accurately control the plasticizing process and product thickness, flatness.

- The GWELL three-roll calender adopts a 45-degree inclined type, which can be raised and lowered freely.

- plate thickness control adopts screw adjustment and press wheel two-way adjustment to control plate thickness.

、

Parameter

| Extruder type | Conical twin-screw extruder GWC92/188 | Conical twin-screw extruder GWC65/132+GWC80/156 | Conical twin-screw extruder GWC80/156 |

| Finished product | Single layer | A/B | A/B/C |

| Net width | 2000-3000mm | 2000-3000mm | 1000-2000mm |

| Thickness range | 0.8-5mm | ||

| Capacity | 550-700kg/h | 450-500kg/h | 350-450kg/h |

| Application | Floor leather | ||

Application

Mainly used for producing the sort of PVC Floor leather rolls.

PVC Floor leather has the function of anti-friction, corrosion resistance, skidproof, impermeable, and inflaming retarding, and is widely used on auto, hotel, amusement place, exhibition hall, house, etc. The structure of this production line is simple, and convenient to operate.

As China Plastic Extruder Supplier, China GWELL is equipped with different components according to customer requirements for the production of single-layer and multi-layer composite production film, etc.

Client

About Gwell

Innovation drives enterprise progress. Relying on the group’s strong technology, equipment strength and innovation spirit, Gwell is committed to the development of high-tech products and the international market. Gwell also actively exchanges and cooperates with world-class scientific research institutions. The new technologies, new processes and new products developed by Gwell are widely used in building materials(PP hollow sheet extrusion machine, PC optic extrusion machine), home appliances(SPC floor extrusion machine), packaging(PET sheet extrusion machine, EVOH film extrusion machine),

medical treatment(PVC rigid sheet extrusion machine), automobiles(TPU film extrusion machine, PVB film extrusion machine), new energy(EVA solar film extrusion machine), aerospace(TPU film extrusion machine), rail transit(waterproof film extrusion machine) and other fields, which are closely related to human life.

Related Product

The main components of the PC Sheet extrusion production line are selected from the world’s high-quality products (such as screws, barrels, rollers, etc.), and its production process is comprehensive. As an excellent supplier of plastic extruders, GWELL’s complete set of production line has approached the world’s high-quality product standards.

As a premier Chinese manufacturer of plastic extrusion machinery, GWELL delivers cutting-edge PS (Polystyrene) Sheet Extrusion Lines engineered for precision, efficiency, and unmatched product consistency. Our advanced extrusion systems are designed to meet the rigorous demands of diverse industries, offering tailored solutions for high-quality PS sheet production.

As a pioneer in PVB interlayer film production machine technology, we specialize in delivering cutting-edge systems designed for high-performance PVB interlayer film manufacturing. Our PVB interlayer film production machines are engineered to meet global industry standards, combining precision, efficiency, and sustainability.

FAQ

What is the main business of GWELL?

Can I go on a field trip to the GWELL factory?

What are the services for purchasing equipment at GWELL?

What types of plastic extrusion machines are available from GWELL?

What is APET PETG CPET Sheet Extrusion Line?

Where does GWELL ship from?

Are there any technical supports for extrusion machine that you need?

Our service will be always at your disposal over the entire extrusion line life.So if you want to know about any other technical supports.Please contact us as soon as possible.

Previous

上一页