PVB Film Production Line

GWELL possesses notable experience in manufacturing PVB film production lines, having built India's very first such line. Our PVB film specifications include: a maximum width of 3600mm (adjustable based on customer requirements), a thickness range of 0.38-1.52mm, and an output range of 500-800kg/h. The total length of one production line is 28m.

Key words:Sheet Extrusion Line

Category:

Film Extrusion Line

Download:

Description

Introduction

Also known as PVB film or PVB intermediate film, PVB film is fundamentally a thermoplastic resin film. It is manufactured using PVB resin and plasticizer, featuring characteristics like recyclability, processability, and reusability. Excellent adhesion to inorganic glass makes PVB film the optimal bonding material for laminated glass. Furthermore, its ability to absorb impact energy ensures laminated glass does not shatter, providing significant safety performance. Additionally, it offers effective sound insulation. Consequently, PVB film sees wide application in car windows, high-rise buildings, and various types of bulletproof glass.

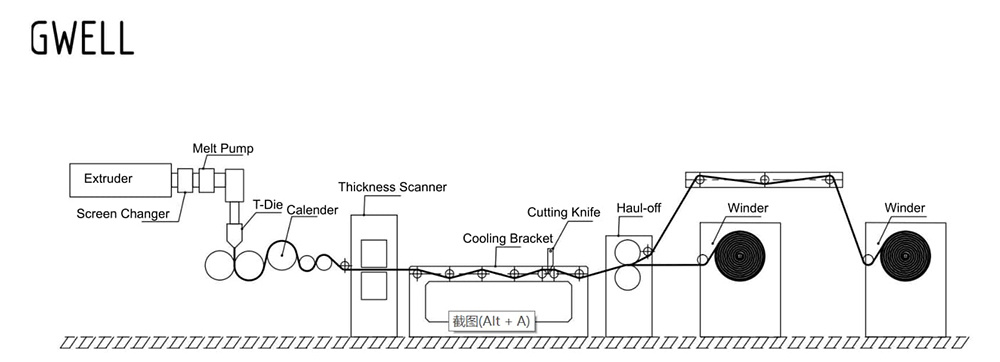

GWELL possesses notable experience in manufacturing PVB film production lines, having built India's very first such line. Our PVB film specifications include: a maximum width of 3600mm (adjustable based on customer requirements), a thickness range of 0.38-1.52mm, and an output range of 500-800kg/h. The total length of one production line is 28m.

Parameter

| Extruder Type | Single screw extruder GWS150, parallel twin screw extruder GWP 95 | parallel twin screw extruder co-extrusion GWP95+GWP52, GWP135+GWP52 |

| Raw material | PVB, SGP | PVB, SGP |

| Layers | single layer | single layer, double layer or three layers |

| Net width | 1500-2800mm | 2400mm-3600mm |

| Thickness range | 0.38-1.52mm | |

| output | 350-600kg/h | 600-980kg/h |

Application

PVB film has a good safety, can prevent glass due to external force broken and caused by splashes hurt, so it is widely used in building laminated glass, automotive laminated glass, solar photovoltaic glass, bulletproof glass, soundproof glass and so on. In addition, it has sound insulation, can also prevent ultraviolet light, can be made of color or high transparency, and has optical application value, such as the application of solar photovoltaic. PVB film has been used in building curtain wall glass for 70 years, and regulations in the automotive and construction industries require the use of PVB film as safety protection. In recent years, with the improvement of people’s requirements for energy conservation and environmental protection, the solar photovoltaic market is changing with each passing day, and the demand for photovoltaic PVB film is becoming more and more obvious.

Client

About Gwell

Innovation drives enterprise progress. Relying on the group’s strong technology, equipment strength and innovation spirit, Gwell is committed to the development of high-tech products and the international market. Gwell also actively exchanges and cooperates with world-class scientific research institutions. The new technologies, new processes and new products developed by Gwell are widely used in building materials(PP hollow sheet extrusion machine, PC optic extrusion machine), home appliances(SPC floor extrusion machine), packaging(PET sheet extrusion machine, EVOH film extrusion machine),

medical treatment(PVC rigid sheet extrusion machine), automobiles(TPU film extrusion machine, PVB film extrusion machine), new energy(EVA solar film extrusion machine), aerospace(TPU film extrusion machine), rail transit(waterproof film extrusion machine) and other fields, which are closely related to human life.

Related Product

The main components of the PC Sheet extrusion production line are selected from the world’s high-quality products (such as screws, barrels, rollers, etc.), and its production process is comprehensive. As an excellent supplier of plastic extruders, GWELL’s complete set of production line has approached the world’s high-quality product standards.

As a premier Chinese manufacturer of plastic extrusion machinery, GWELL delivers cutting-edge PS (Polystyrene) Sheet Extrusion Lines engineered for precision, efficiency, and unmatched product consistency. Our advanced extrusion systems are designed to meet the rigorous demands of diverse industries, offering tailored solutions for high-quality PS sheet production.

As a pioneer in PVB interlayer film production machine technology, we specialize in delivering cutting-edge systems designed for high-performance PVB interlayer film manufacturing. Our PVB interlayer film production machines are engineered to meet global industry standards, combining precision, efficiency, and sustainability.

FAQ

What is the main business of GWELL?

Can I go on a field trip to the GWELL factory?

What are the services for purchasing equipment at GWELL?

What types of plastic extrusion machines are available from GWELL?

What is APET PETG CPET Sheet Extrusion Line?

Where does GWELL ship from?

Are there any technical supports for extrusion machine that you need?

Our service will be always at your disposal over the entire extrusion line life.So if you want to know about any other technical supports.Please contact us as soon as possible.