Products

Gwell’s extrusion technology satisfies customers with the highest economic efficiency

China’s professional plastic extruder suppliers are always exploring new paths for plastic sheet, film, sheet extruders

PRODUCTS CENTER

As a pioneer in PVB interlayer film production machine technology, we specialize in delivering cutting-edge systems designed for high-performance PVB interlayer film manufacturing. Our PVB interlayer film production machines are engineered to meet global industry standards, combining precision, efficiency, and sustainability.

Our TPU film production line, ranging from 1372-1520mm in width and 0.02-3.0mm in thickness, ensures precise temperature control and high transparency. The TPU laminating extrusion line efficiently combines TPU film with fabrics, reducing costs and enhancing product quality across diverse applications.

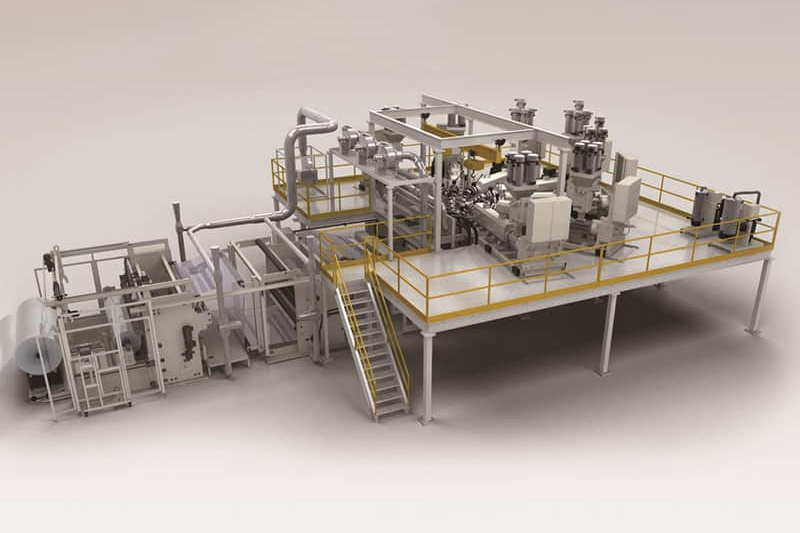

EVOH resin, with exceptional barrier properties, is extensively utilized in food packaging, automotive fuel tanks, films, and heating pipes, thanks to its versatility in meeting diverse production specifications through the EVOH multi-layer film extrusion line.

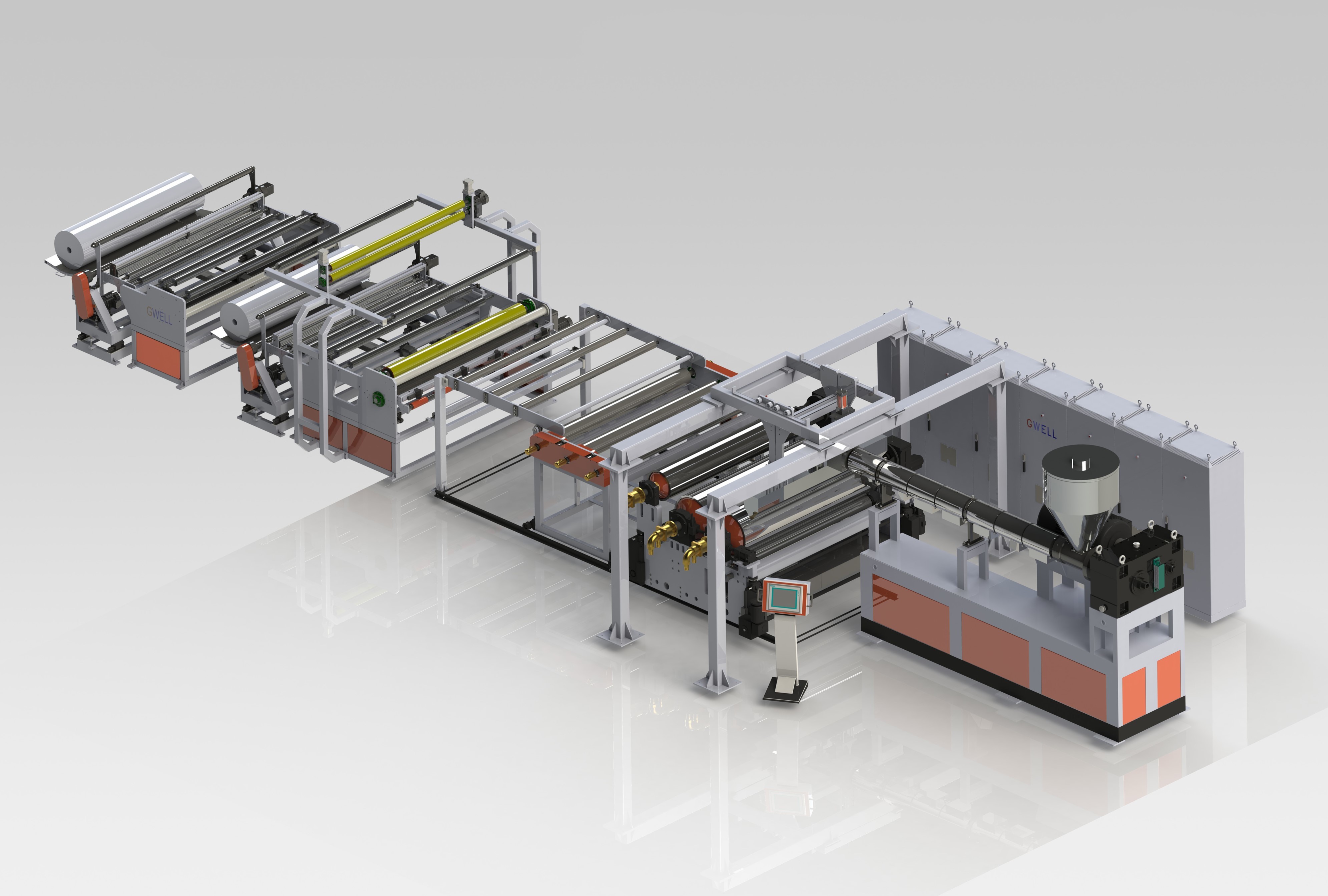

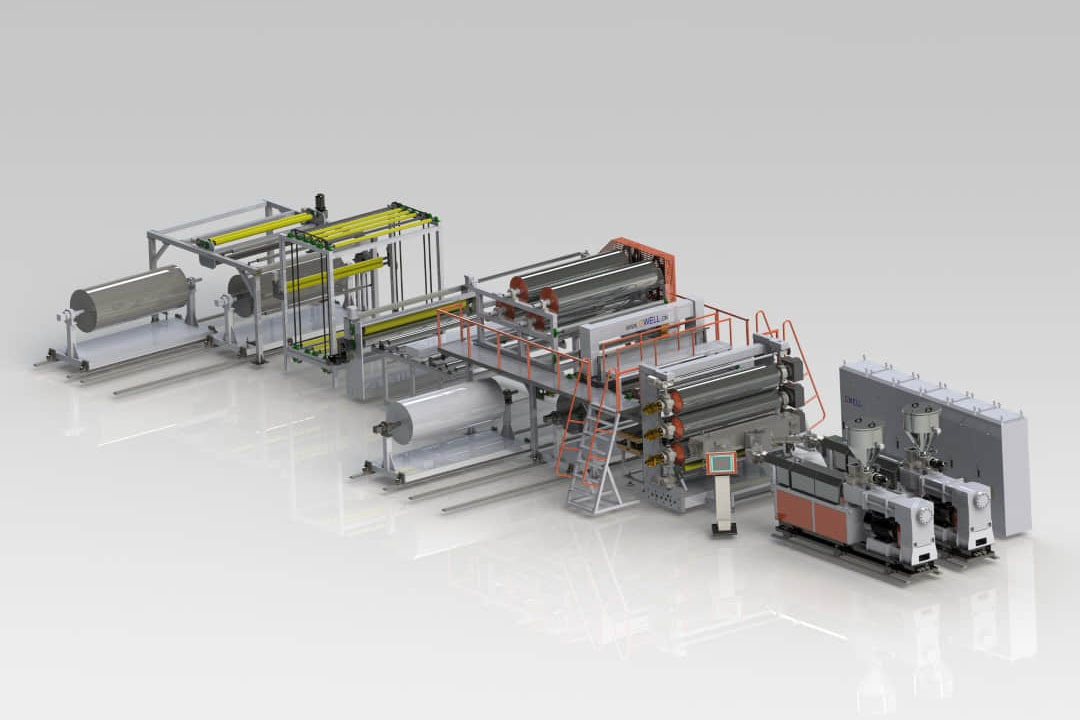

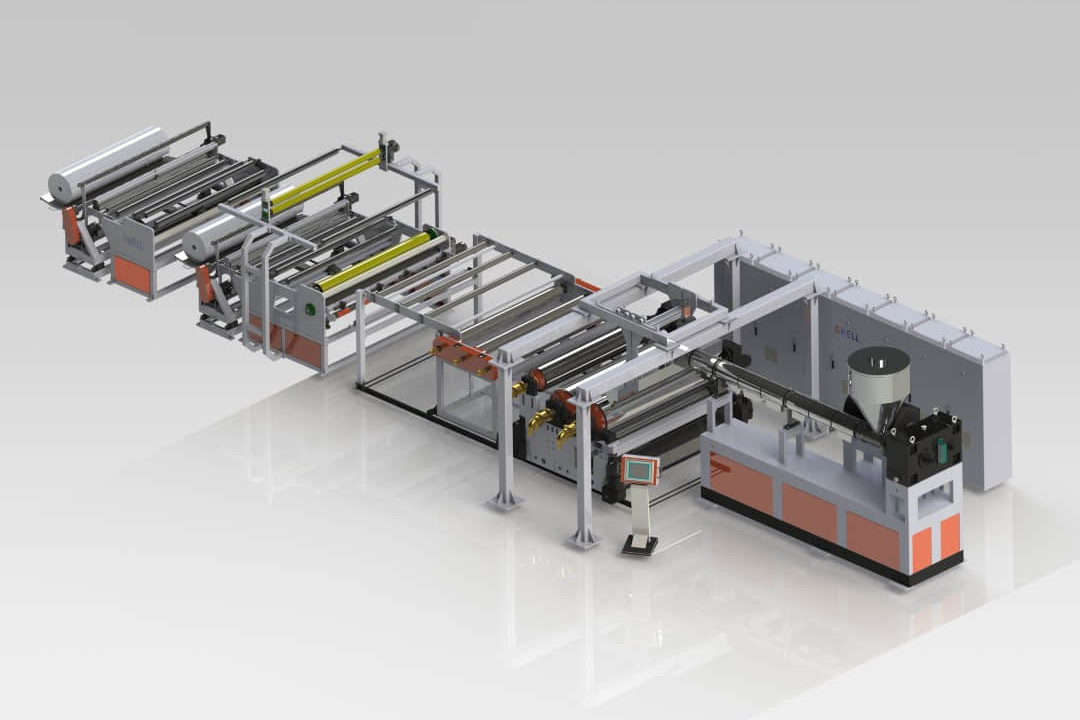

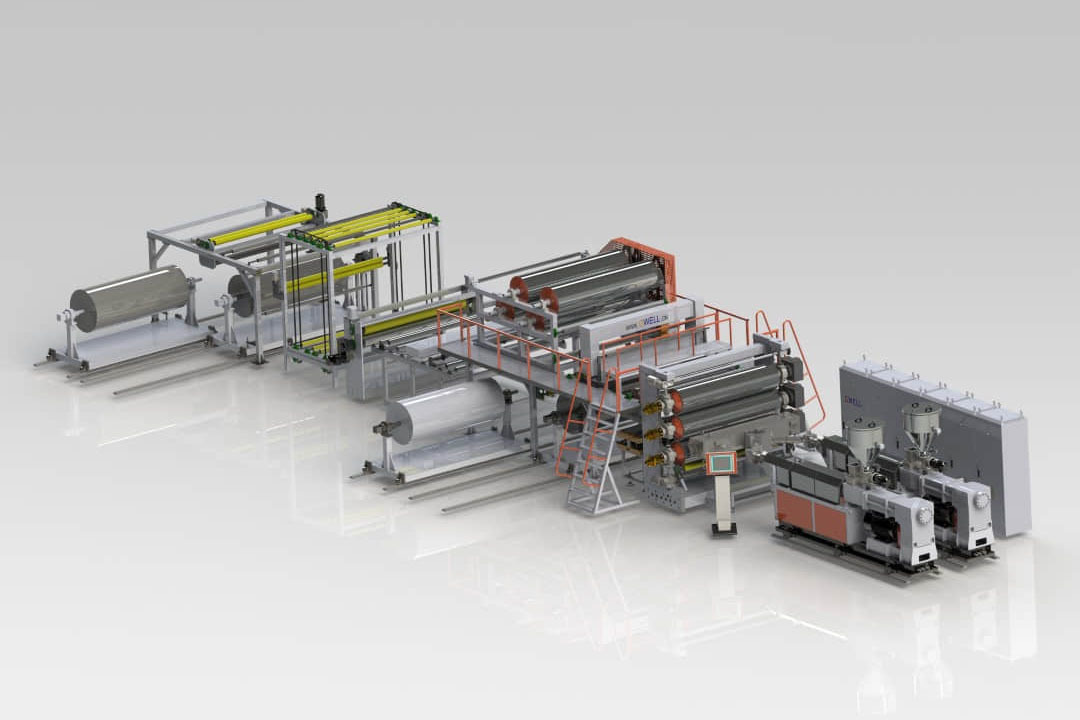

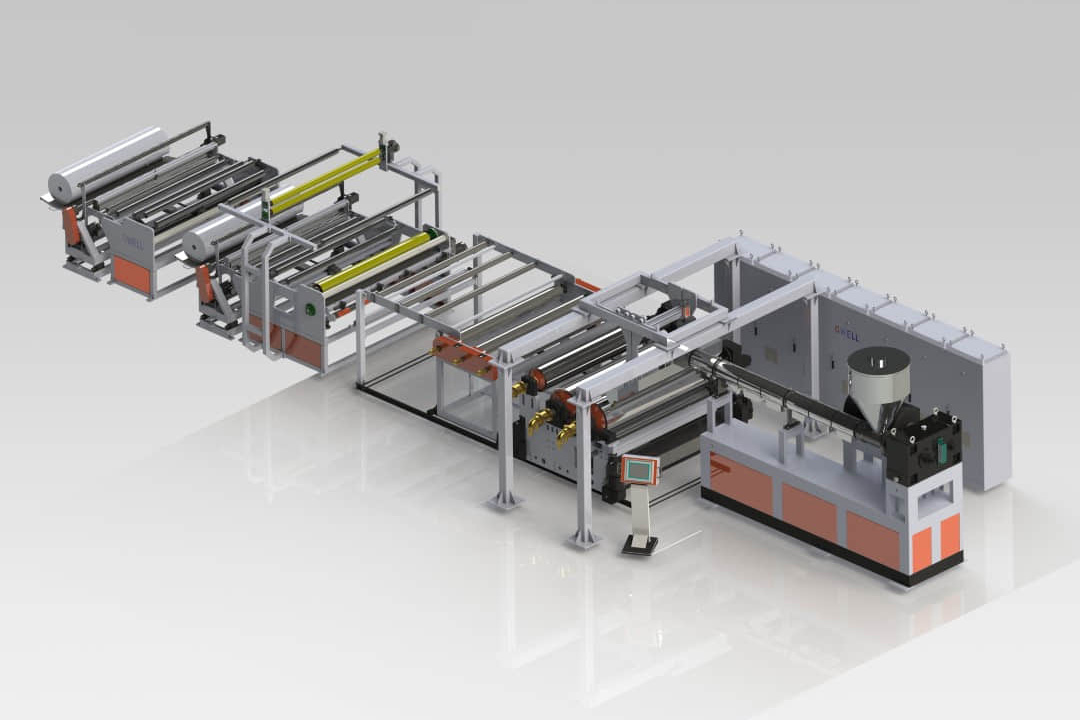

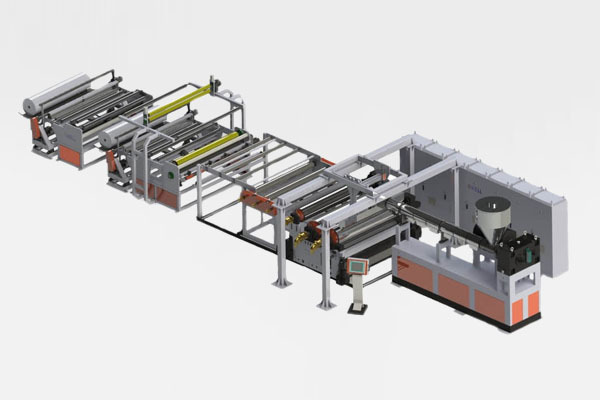

GWELL possesses notable experience in manufacturing PVB film production lines, having built India's very first such line. Our PVB film specifications include: a maximum width of 3600mm (adjustable based on customer requirements), a thickness range of 0.38-1.52mm, and an output range of 500-800kg/h. The total length of one production line is 28m.

China GWELL as China Plastic Extruder Supplier, EVOH multi-layer film extrusion line adopts precision dispensing technology, proportional metering, fixed flow channel, more accurate layering and more stable pressure. The whole line adopts man-machine interface display, PLC control, frequency conversion speed regulation, online powder cleaning, and automatic cleaning.

The TPU film extrusion line covers both release film and patch. As China Plastic Extruder manufacturer, GWELL adopts PLC control for the whole line, which can be easily controlled by one person. The disassembly and replacement of key components is convenient and user-friendly. The remote control port is reserved for simultaneous monitoring around the world. The product has high transparency, few crystallization points, and no bubbles during winding.

The PVB/SGP film extrusion line exists in two distinct variants. One employs a dry process (also termed the roll method), where extruded film undergoes stretching, air-cooling, shaping, and winding. The alternative utilizes a wet process (known as the watercraft method), involving film extrusion, stretching, cooling and shaping within a water tank, followed by blow-drying prior to winding.

As China Plastic Extruder manufacturer, China GWELL’s PETG film extrusion line adopts multi-machine co-extrusion technology to produce multi-layer co-extruded composite PET sheets such as APET/PETG, PETG/APET/PETG, APET/RPET/APET, etc. Plastic blister, printing, hardware bags, gift folding boxes, etc.

GWELL as China Plastic Extruder Supplier, ASA film extrusion line adopts PLC and closed-loop control, which can realize one-key acceleration and simple operation. The special screw design of the extruder ensures the melting of plastic raw materials, the uniform color of the product and the large extrusion volume.

GWELL as China Plastic Extruder manufacturer, CPP CPE film extrusion line adopts single-machine or multi-machine co-extrusion method to produce single-layer or multi-layer co-extrusion cast film, and multiplier can also be used to realize the production of up to 72 layers of cast film, fully imported metering pump, digital and precise control Material percentage, to achieve precise input of special materials and reduce costs.

GWELL as China Plastic Extruder Supplier, PE ventilated film extrusion line is composed of: raw material automatic feeding system, twin-screw extruder mixing host, screw pump, extrusion molding system, stretch forming system, cooling and winding system. The PE ventilated film extrusion line can continuously complete the process of conveying raw materials, mixing, dispersing, casting extrusion, stretching and shaping, and winding.

GWELL as China Plastic Extruder manufacturer, PE PVC cling film extrusion line uses PVC resin powder as the main raw material, mixes various grades of additives, and produces PVC plastic wrap with self-adhesive properties by thoroughly stirring and plasticizing extrusion through an extruder. The winding method adopts an advanced and highly automated four-axis winding system, touch screen operation, PLC control, electrostatic lamination system, no need for adhesive tape, saving material and labor costs.