ABOUT

Gwell’s extrusion technology satisfies customers with the highest economic efficiency

China’s professional plastic extruder suppliers are always exploring new paths for plastic sheet, film, sheet extruders

Your Trust Is Our Responsibility

Brand meaning: Gwell–Global Well Presentation

Company culture: Prompt Patient Professional Perfect

Core competence: product cost performance, fast service response, large customization scale

Quality policy: economic application, continuous improvement, and professional service

Development concept: take the striver as the center and the customer as the center

Development strategy: focus on the plane forming industry, be an innovation-driven enterprise, take the lead in science and technology, and serve customers

Core values and vision: Professional shaping customer value, Creating and realizing employee value, Technology reflects product value

Years Experience

Project Done

Happy Clients

Awards Won

Our Client

We Have Worked With Brands

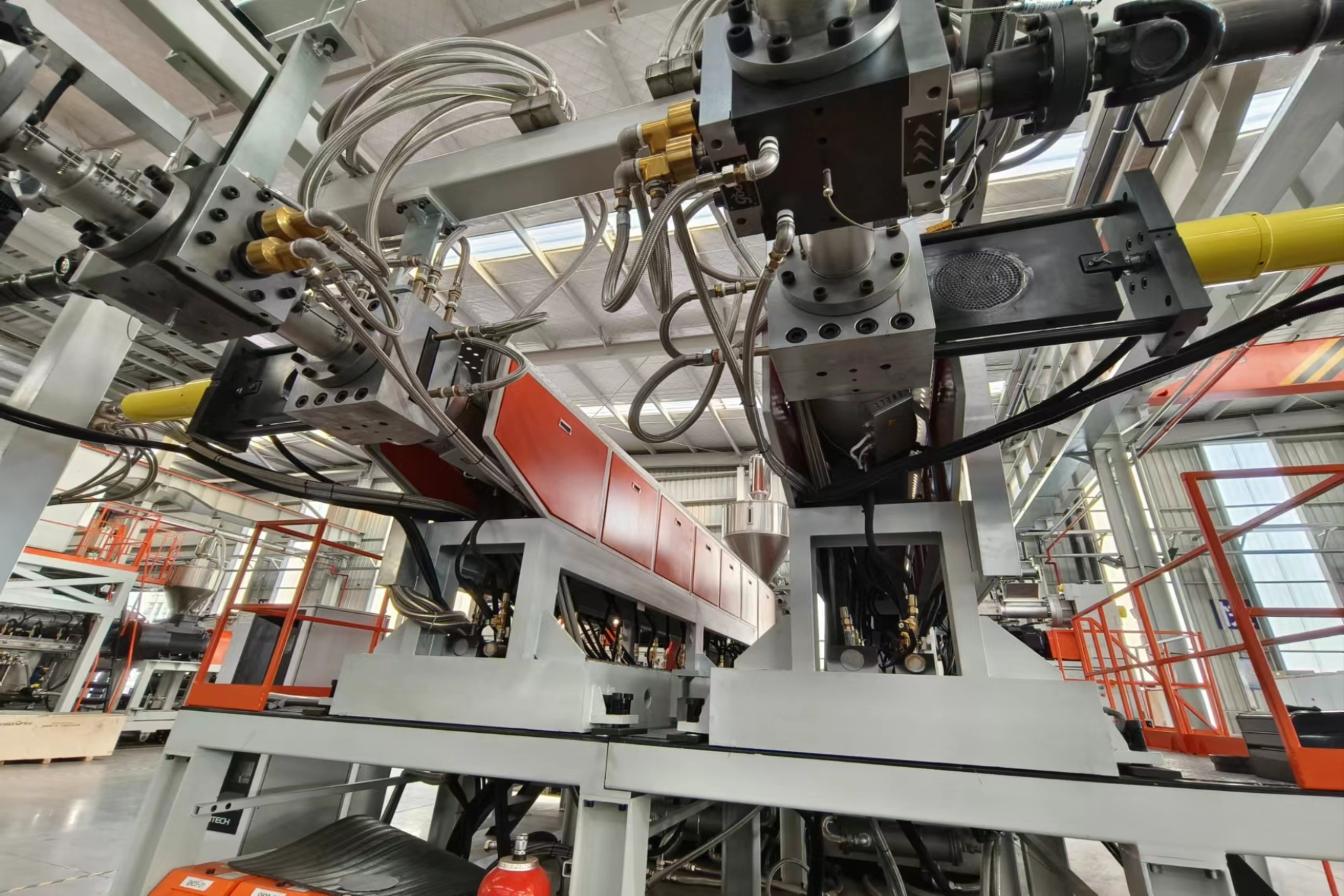

Gwell Extrusion Line Manufacturer has been committed to plastic solar extrusion line, sheet extrusion line, film extrusion line, etc. Our extruders stand out for their ease of use, application flexibility, and zero-waste technology to achieve the highest economic benefits and support satisfying customers’ needs need.

Solar extrusion line

can be EVA,POE,PVDF, etc.

Thickness is flexible.

Width and Application is based on target market. Output capacity requirements can be designed on the basis of Gwell technology.

Sheet extrusion line

Raw material can be PET,PP,PS,PLA,PC,PETG,PMMA, etc.

Thickness is around 0.15-0.2mm and flexible.

Width and Application is based on target market.Output capacity requirements can be designed on the basis of Gwell technology.

Film extrusion line

Raw material can be EVA,PETG,TPU,EVOH,ASA,ETFE, etc.

Thickness is around 0.015-0.15mm and flexible.

Width and Application is based on target market,like packaging,printing,etc.Output capacity requirements can be designed on the basis of Gwell technology.

Board extrusion line

Raw material can be PVC,TPO,EVA, etc.

Thickness is flexible.

Width and Application is based on target market,like construction,soft curtain etc.Output capacity requirement can be designed on the basis of Gwell technology.

Hollow extrusion line

Raw material can be PP,PC,PE, etc.

Thickness is flexible.

Width and Application is based on target market like packaging,etc.Output capacity requirement can be designed on the basis of Gwell technology.

Waterproof extrusion line

Raw material can be PVC,TPO,EVA, etc.

Thickness is flexible.

Width and Application is based on target market,like construction,etc.Output capacity requirement can be designed on the basis of Gwell technology.

Our Hisotry

We Have Many Years Of Design And Production Experience

Our Team Company

Extrusion Line Manufacturer Provide Employees With A Comfortable Working Environment

Factory

Reception

Office

E-Cabinet Workshop

Worker

Gantry Machine

Warehouse

Warehouse

Message

Today You Find GWELL, Tomorrow You Will Choose Us

We’ll be pleased to show the advantages and demonstrate to you the performance of the GWELL solar extrusion line or sheet extrusion line. Please provide the contact information, you will be contacted as soon as we receive your inquiry form.

Online Service