EVA POE Solar Film Production Line

Our EVA/POE film extrusion lines produce solar cell encapsulation films with superior low-shrinkage properties. GWELL delivers fully integrated production systems - from feeding to calibration - in a single streamlined solution. GWELL Machinery's EVA/POE film extrusion lines hold an unrivaled global leadership position in this specialized field.

Key words:Sheet Extrusion Line

Category:

EVA POE solar film extrusion line

Description

GWELL MANUFACTURING - EVA POE SOLAR FILM PRODUCTION LINE

Our EVA/POE film extrusion lines produce solar cell encapsulation films with superior low-shrinkage properties. GWELL delivers fully integrated production systems - from feeding to calibration - in a single streamlined solution.

GWELL Machinery's EVA/POE film extrusion lines hold an unrivaled global leadership position in this specialized field.

Advanced Processing Technology

- Using double-station automatic rewinding and rewinding device

- Magnetic powder tension design

- Constant tension control

- The production acceleration and deceleration can be controlled by the synchronization ratio

- Online waste recycling system

- The speed can reach 50m/min, 100m/min, 150m/min.

Components and Description:

1. Fully automatic continuous weighing and feeding system

Our advanced feeding system delivers continuous precision while enabling rapid formulation adjustments – ensuring your production stays ahead of market demands and technological advancements.

Key Advantages:

✔ Intelligent Gravimetric Control – Maintains ±0.3% feeding accuracy for consistent quality

✔ On-the-Fly Formula Switching – Adapt to new material requirements without downtime

✔ Recipe Management System – Store and recall formulations with one-touch operation

Why It Matters:

The foundation of superior EVA/POE film begins with perfect raw material proportioning. Our system ensures:

-

Flawless additive incorporation

-

Immediate response to formulation changes

-

Repeatable quality across production batches

2. Innovative Single-Screw Extrusion Technology

Our production line features advanced direct extrusion technology centered around a precision-engineered single-screw extruder. This core innovation enables:

✓ In-line compounding of EVA/POE resins with multiple additives

✓ Superior material homogeneity without pre-crosslinking

✓ Significant reduction in operational costs

Technical Superiority Through Expertise

• Proprietary screw design tailored to EVA/POE resin characteristics:

-

Optimized element geometry based on material rheology

-

Precision-engineered flight profiles for maximum efficiency

• Achieves exceptional mixing performance critical for: -

Uniform additive dispersion

-

Consistent film quality

-

High-volume production stability

Proven Performance Advantages

This technology breakthrough results from our:

✓ 15+ years of specialized extrusion expertise

✓ Deep understanding of polymer processing dynamics

✓ Continuous R&D investment in screw design innovation

The system delivers:

• 30% higher output efficiency compared to conventional systems

• 99.5% material homogeneity rate

• 50% reduction in energy consumption per unit output

3. Precision Temperature Control & cooling system

• Our patented cooling system maintains exceptional temperature uniformity across the entire calender surface

• Specialized silicon-coated rollers actively relieve internal stresses in EVA/POE film

• Delivers industry-leading dimensional stability with minimized shrinkage rates

German-Engineered Melt Delivery System

• Premium German-made gear pump ensures:

-

Precise melt volume control (±0.5%)

-

Ultra-stable pressure output

-

Consistent material flow to die head

• Smart closed-loop control system maintains: -

Continuous operational stability

-

Automatic parameter adjustments

-

Optimal production efficiency

4. Calibration system

The unique T-die for EVA/POE is designed according to the extrusion rheology of solar cell grade EVA/POE resin to ensure stable extrusion at low temperature.This is one of the conditions that guarantees low shrinkage and high light transmittance.

Our extrusion line features an automatic online thickness gauge for real-time monitoring and reporting of film thickness, ensuring consistent product quality.

The precision winding system is specially engineered to account for the mechanical properties of EVA/POE film, maintaining constant tension for superior roll formation.

Through continuous optimization in long-term production, our system achieves:

✔ Minimal edge trim waste

✔ Higher production yield

✔ Significant reduction in operating costs

5. Advanced Control System for Precision Extrusion

From basic relays to industrial-grade PLCs, our systems offer flexible control configurations to match your production needs.

Key Advantages:

✔ Modular Logic Control – Intuitive function-based programming ensures precise, effortless operation.

✔ Built-in Safety – Comprehensive mechanical and electrical safeguards minimize risks for fail-safe production.

✔ Seamless Synchronization – Tightly coordinated unit control delivers consistent, high-quality output.

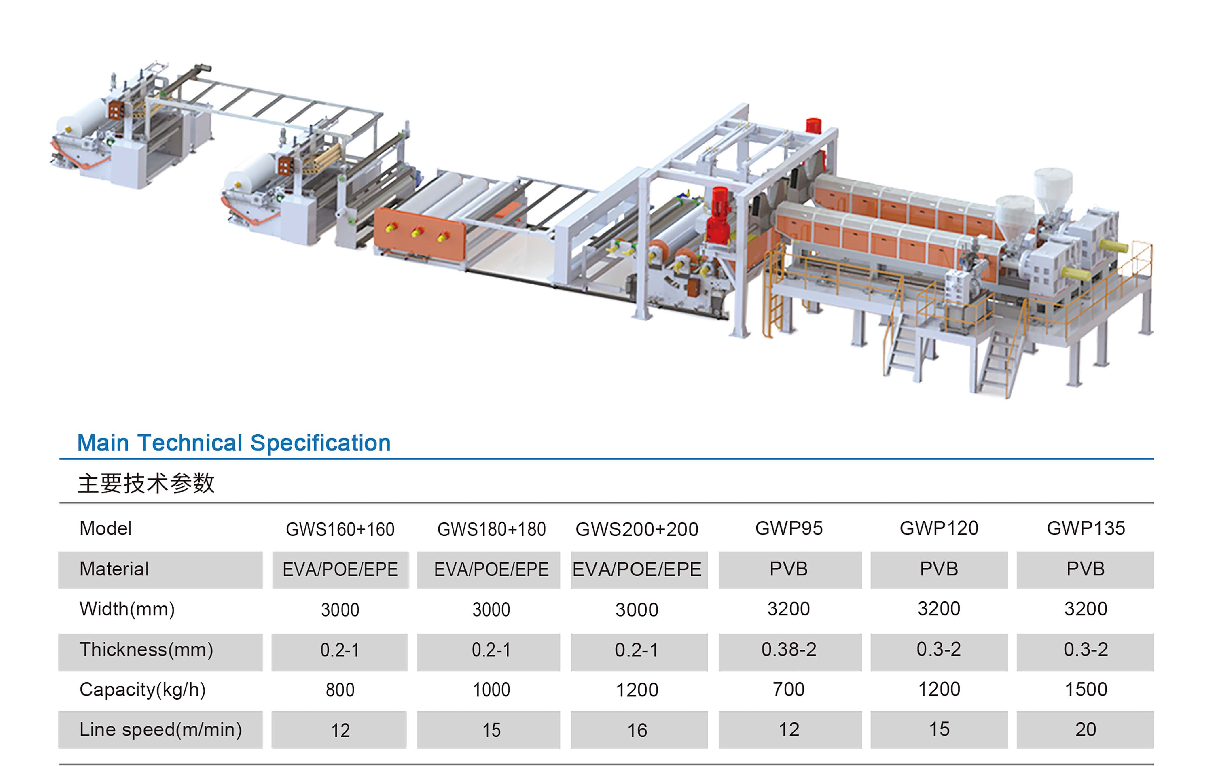

Parameter

Application

Application:

EVA encapsulation film is mainly used for crystalline silicon and solar module package.

For theEVA film's superior adhesion, durability, andoptical characteristics, it is more and more widely used in thesolar cell module and many optical products.

Client

About Gwell

Innovation drives enterprise progress. Relying on the group’s strong technology, equipment strength and innovation spirit, Gwell is committed to the development of high-tech products and the international market. Gwell also actively exchanges and cooperates with world-class scientific research institutions. The new technologies, new processes and new products developed by Gwell are widely used in building materials(PP hollow sheet extrusion machine, PC optic extrusion machine), home appliances(SPC floor extrusion machine), packaging(PET sheet extrusion machine, EVOH film extrusion machine),

medical treatment(PVC rigid sheet extrusion machine), automobiles(TPU film extrusion machine, PVB film extrusion machine), new energy(EVA solar film extrusion machine), aerospace(TPU film extrusion machine), rail transit(waterproof film extrusion machine) and other fields, which are closely related to human life.

Related Product

The main components of the PC Sheet extrusion production line are selected from the world’s high-quality products (such as screws, barrels, rollers, etc.), and its production process is comprehensive. As an excellent supplier of plastic extruders, GWELL’s complete set of production line has approached the world’s high-quality product standards.

As a premier Chinese manufacturer of plastic extrusion machinery, GWELL delivers cutting-edge PS (Polystyrene) Sheet Extrusion Lines engineered for precision, efficiency, and unmatched product consistency. Our advanced extrusion systems are designed to meet the rigorous demands of diverse industries, offering tailored solutions for high-quality PS sheet production.

As a pioneer in PVB interlayer film production machine technology, we specialize in delivering cutting-edge systems designed for high-performance PVB interlayer film manufacturing. Our PVB interlayer film production machines are engineered to meet global industry standards, combining precision, efficiency, and sustainability.

FAQ

What is the main business of GWELL?

Can I go on a field trip to the GWELL factory?

What are the services for purchasing equipment at GWELL?

What types of plastic extrusion machines are available from GWELL?

What is APET PETG CPET Sheet Extrusion Line?

Where does GWELL ship from?

Are there any technical supports for extrusion machine that you need?

Our service will be always at your disposal over the entire extrusion line life.So if you want to know about any other technical supports.Please contact us as soon as possible.

Previous

下一页