Products

Gwell’s extrusion technology satisfies customers with the highest economic efficiency

China’s professional plastic extruder suppliers are always exploring new paths for plastic sheet, film, sheet extruders

PRODUCTS CENTER

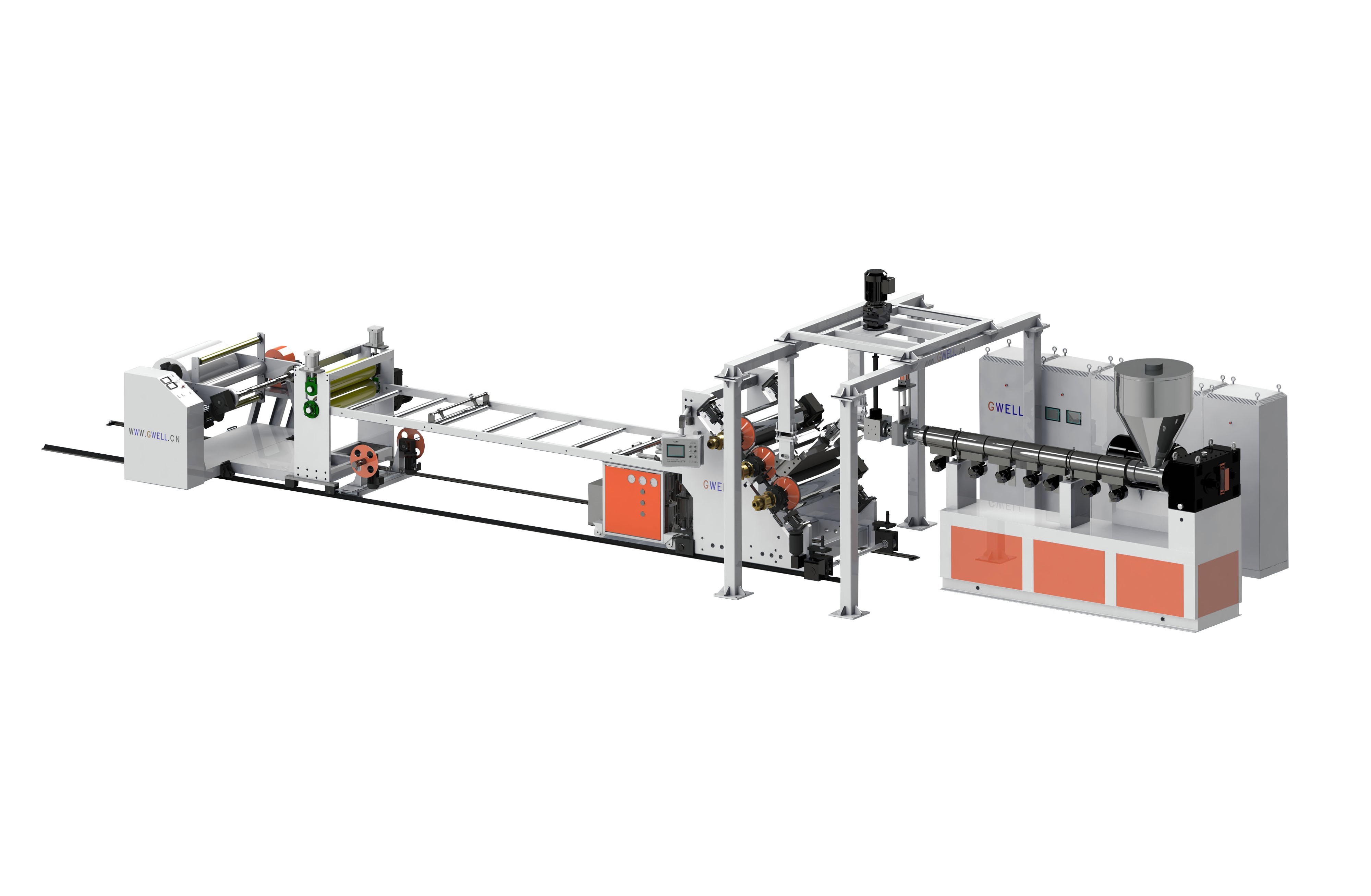

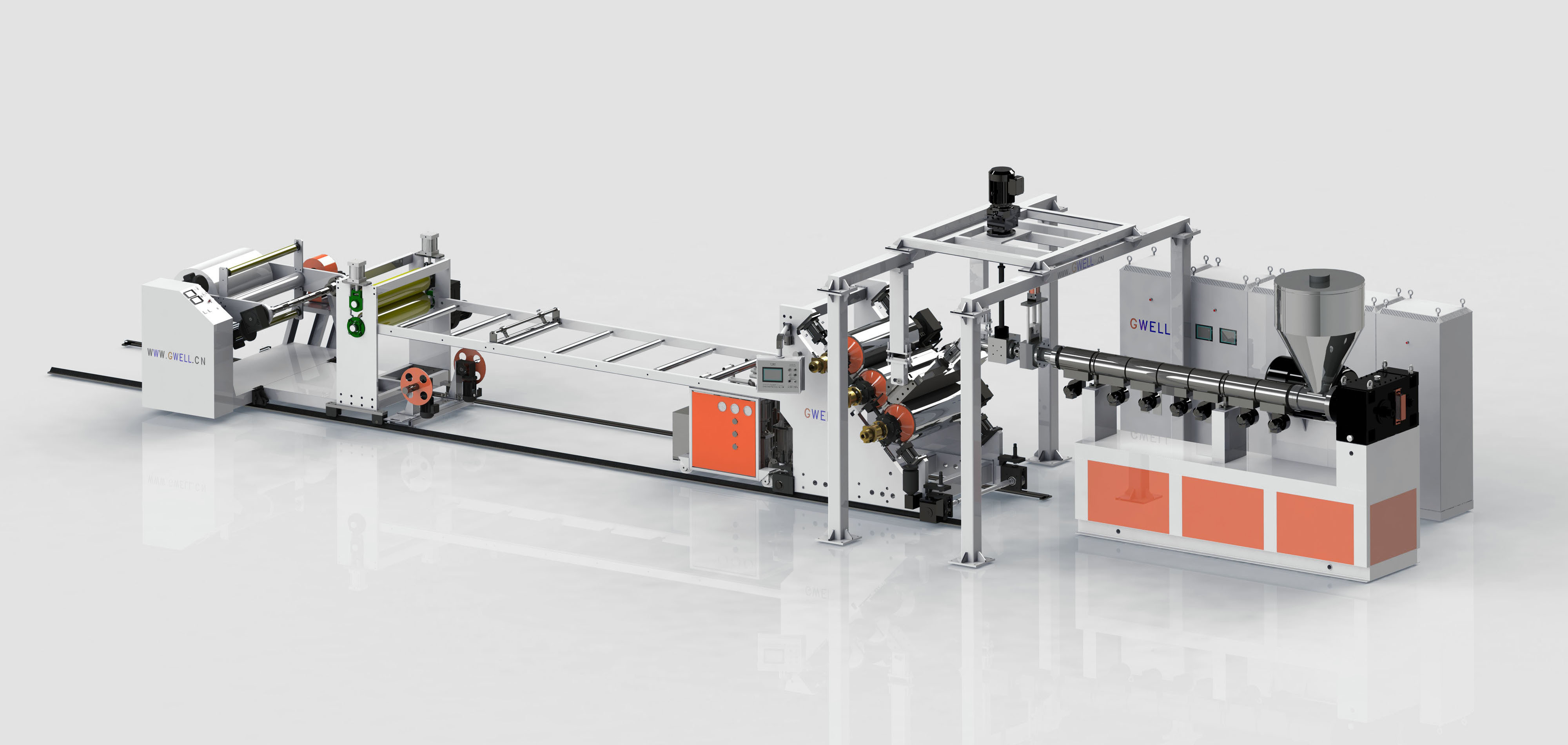

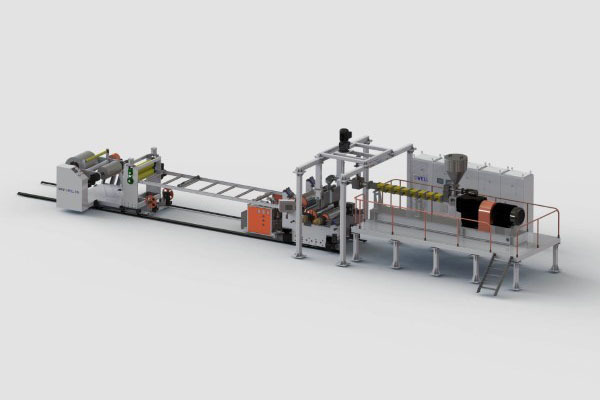

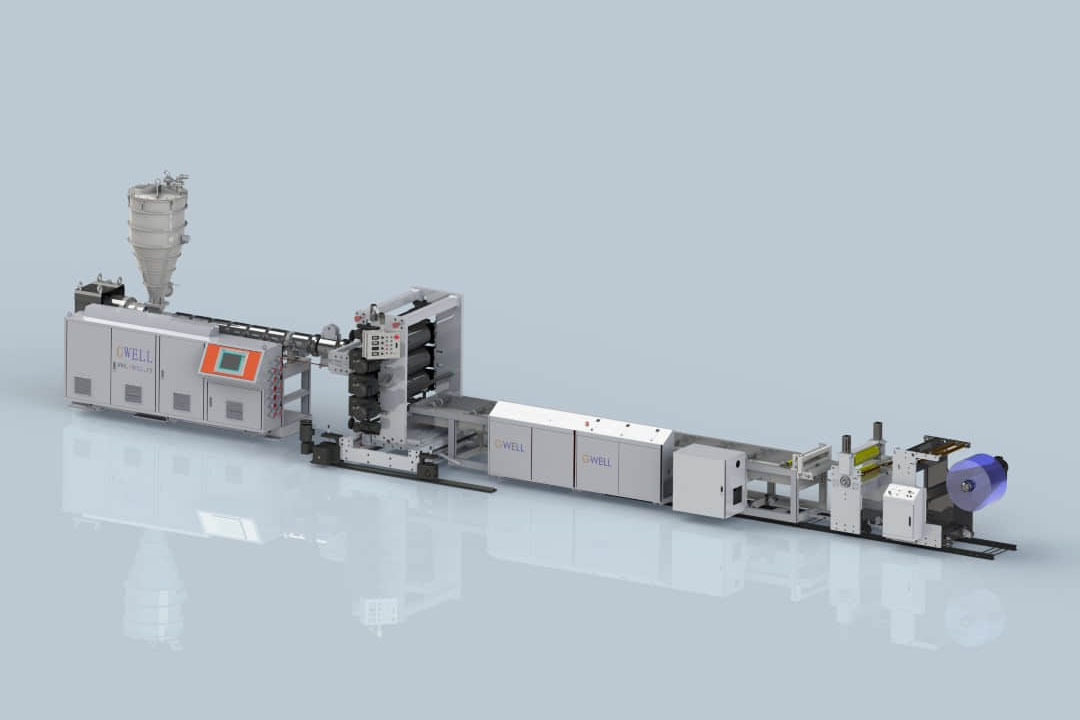

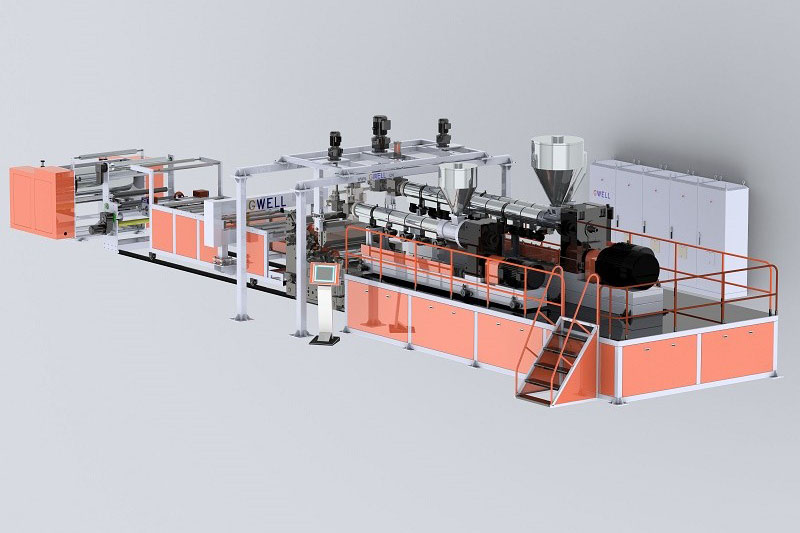

The main components of the PC Sheet extrusion production line are selected from the world’s high-quality products (such as screws, barrels, rollers, etc.), and its production process is comprehensive. As an excellent supplier of plastic extruders, GWELL’s complete set of production line has approached the world’s high-quality product standards.

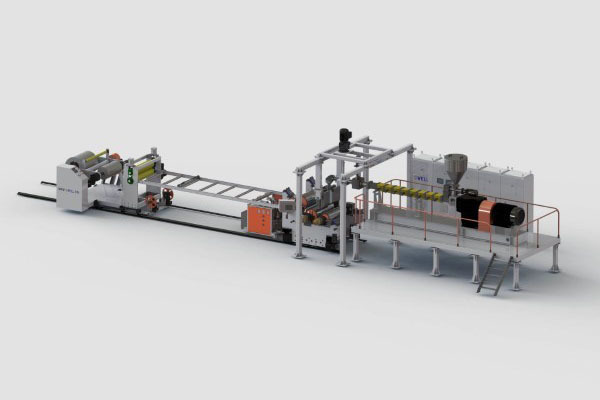

As a premier Chinese manufacturer of plastic extrusion machinery, GWELL delivers cutting-edge PS (Polystyrene) Sheet Extrusion Lines engineered for precision, efficiency, and unmatched product consistency. Our advanced extrusion systems are designed to meet the rigorous demands of diverse industries, offering tailored solutions for high-quality PS sheet production.

The PP, PS multi-layer co-extruded sheet production line utilizes advanced extrusion technology to produce versatile sheets for applications like thermoforming and packaging, offering precise control, high output, and environmental benefits.

A PET sheet production line continuously manufactures PET (Polyethylene Terephthalate) sheets by melting resin, extruding, cooling, and winding for applications like packaging and thermoforming.

Unleash the potential of PET sheet production with our state-of-the-art PET sheet extrusion lines. This cutting-edge equipment delivers precision, efficiency and versatility, allowing you to produce high-quality PET sheets suitable for a variety of applications.

The PP Sheet Extrusion Line is your gateway to efficient and high-quality polypropylene sheet production. This state-of-the-art equipment ensures precision, consistency, and cost-effectiveness in crafting PP sheets for various applications. Upgrade your manufacturing with this advanced extrusion line.

pp, evoh multi-layer barrier sheet extrusion line: Due to the increasingly stringent requirements of the market for products, the advanced five-layer symmetric and seven-layer asymmetric distribution technology has been developed, so that the products produced by this equipment have better barrier performance. At present, GWELL can integrate EVOH into 7-layer, 9-layer or 11-layer structure through multi-layer co-extrusion process.

Gwell as China Plastic Extruder Supplier, PVC Soft Sheet Extrusion Line A single-screw extruder is used to extrude PVC pellets. The unique screw structure, combined with China Gwell vacuum hopper, makes the product achieve a highly transparent effect, and the product will not harden at a low temperature of 30 degrees below zero.

GWELL PET three layers GAG sheet extrusion line can cover single or double sides according to customer needs and can customize different sizes for customers to meet the needs of making cylinders, boxes, windows and other products.

APET PETG CPET sheet extrusion line is improved from PET sheet production equipment. Depending on the type of extruder, there are different raw material processing methods. GWELL’s single-screw or twin-screw extruders can be used to produce three-layer PET sheets.

GWELL as China Plastic Extruder Supplier, PLA PBS PBAT Starch Straw Sheet Extrusion Line is suitable for PLA (PLA) and modified PLA. The whole machine is controlled by PLC, and functions such as actual parameter setting, data operation, feedback, and alarm are automated. Using multi-extruder co-extrusion technology, multi-layer co-extrusion composite PLA or starch sheets can be produced. Widely used in thermoforming, printing, metal packaging, etc.

GWELL as China Plastic Extruder manufacturer, The PC/PMMA extrusion line equipment manufactured by GWELL, has advantages in energy consumption, intelligence, automation indicators, safety standards, process standards, etc. replaces imported equipment, but it has cost-effective advantages.