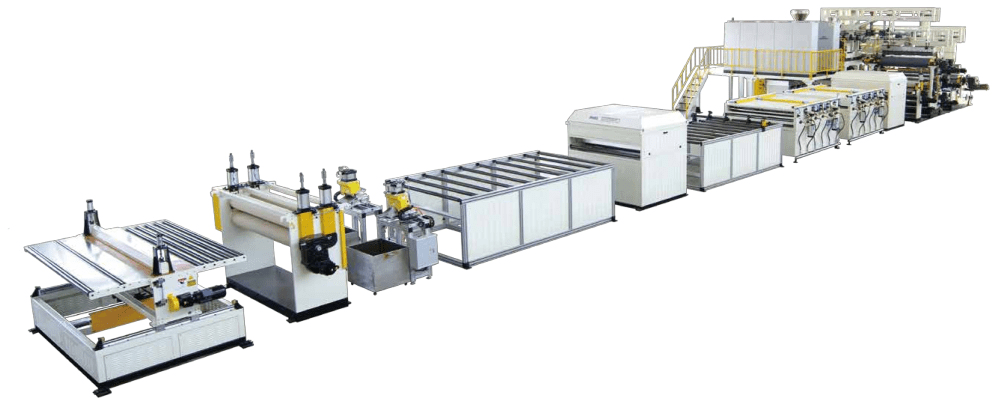

PP Honey Comb Board Extrusion Line

PP honey comb board extrusion line is a new product developed by China GWELL on the basis of traditional sheet machinery and adapted to the production of honeycomb panels.

Key words:Sheet Extrusion Line

Category:

Hollow Extrusion Line

Download:

Description

Gwell PP Honeycomb Board Extrusion Line Feature

Honeycomb board extrusion line is a new product that GWELL, as ChinaPlastic Extruder manufacturer, innovates on the basis of traditional sheet machinery and adapts to the production of honeycomb panels.

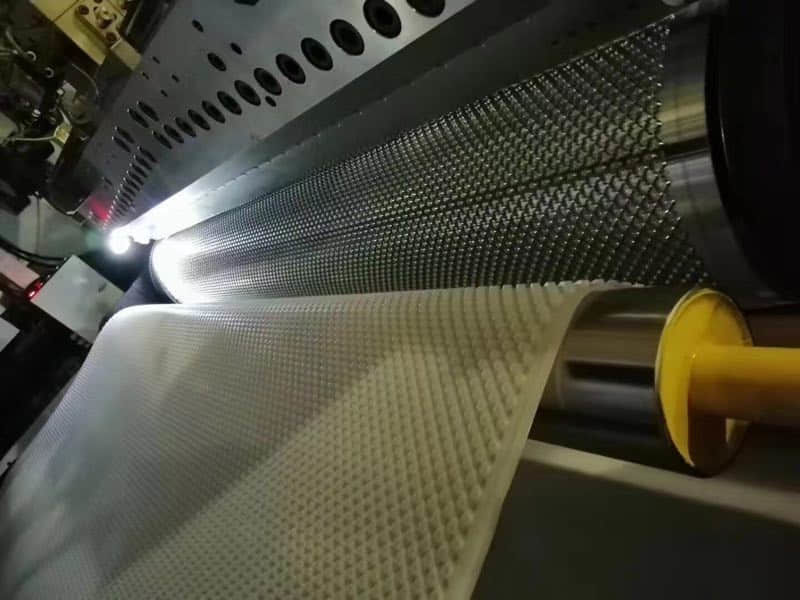

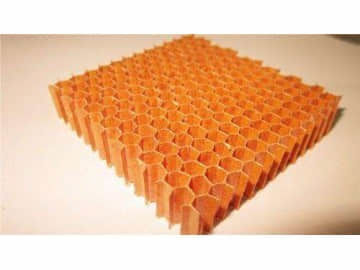

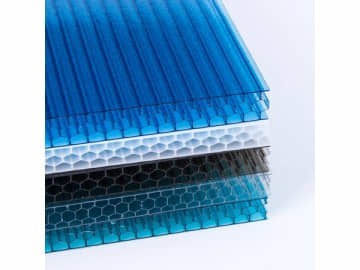

A honeycomb plate is a plate made of two thin panels firmly bonded to both sides of a thick honeycomb core material, also known as a honey comb sandwich structure.

Honeycomb core material is a whole core material with hexagonal and circular hollow (honeycomb) formed by processing and bonding PC (polycarbonate) and PP (polypropylene). Commonly used panels are PC, PMMA, PETG, etc. The panel must be firmly bonded with the core material with an appropriate adhesive to show the excellent characteristics of the honeycomb panel, that is, it has many functions, such as high specific strength, low thermal conductivity, and good seismic resistance.

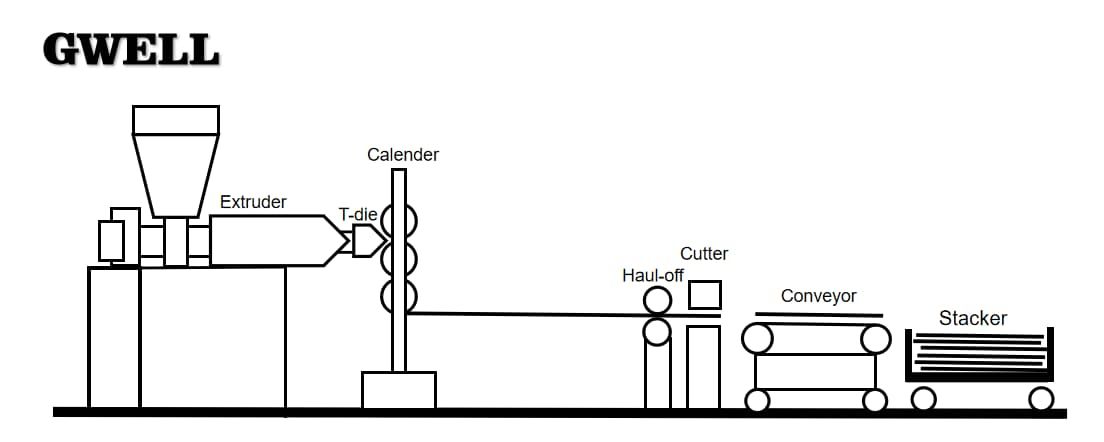

PP Honeycomb Board Extrusion Line Process Flows

Extruder —– T-die —— Calender —- Haul-off —-Cutter —-Conveyor —- Stacker

Advantages of honeycomb board:

It has long-lasting moisture-proof and anti-corrosion performance. By adding different plastic additives, it can realize other functions such as UV resistance, fire prevention, and flame retardant

- Strong compression and impact resistance; PP honeycomb plate absorbs external force, so as to reduce the damage caused by impact and collision.

- Lightweight; PP honeycomb panel is light in weight, which can reduce d the load weight of transportation tools, thus reducing the speed of transportation tools and the cost of transportation.

- Sound insulation performance; PP honeycomb plate can reduce the diffusion and propagation of sound.

- Thermal insulation performance; PP honeycomb panel has excellent thermal insulation performance and can block the propagation of heat.

- Water and corrosion resistance; Due to the characteristics of its raw materials, it can be used in high water content and corrosive environment for a long time.

Parameter

| Extruder Type | GWS75/75/75, GWS100/100/100, and more |

| Raw material | PP, PC, and more |

| Net width | 1200-2000mm |

| Thickness range | 2-20mm |

| Capacity | 350-700kg/h |

| Application | In the car industry, aerospace, yachts and ships, rail transit, logistics and transportation, building decoration, human body protection, etc |

Application

- It is applied to the luggage compartment cover, luggage compartment partition, luggage compartment carpet base plate, side wall trim panel, ceiling and other interior parts of passenger cars;

- It is used to make various strength packing boxes.

Automobile honeycomb board cover plate, automobile interior honeycomb board.

Client

About Gwell

Innovation drives enterprise progress. Relying on the group’s strong technology, equipment strength and innovation spirit, Gwell is committed to the development of high-tech products and the international market. Gwell also actively exchanges and cooperates with world-class scientific research institutions. The new technologies, new processes and new products developed by Gwell are widely used in building materials(PP hollow sheet extrusion machine, PC optic extrusion machine), home appliances(SPC floor extrusion machine), packaging(PET sheet extrusion machine, EVOH film extrusion machine),

medical treatment(PVC rigid sheet extrusion machine), automobiles(TPU film extrusion machine, PVB film extrusion machine), new energy(EVA solar film extrusion machine), aerospace(TPU film extrusion machine), rail transit(waterproof film extrusion machine) and other fields, which are closely related to human life.

Related Product

The main components of the PC Sheet extrusion production line are selected from the world’s high-quality products (such as screws, barrels, rollers, etc.), and its production process is comprehensive. As an excellent supplier of plastic extruders, GWELL’s complete set of production line has approached the world’s high-quality product standards.

As a premier Chinese manufacturer of plastic extrusion machinery, GWELL delivers cutting-edge PS (Polystyrene) Sheet Extrusion Lines engineered for precision, efficiency, and unmatched product consistency. Our advanced extrusion systems are designed to meet the rigorous demands of diverse industries, offering tailored solutions for high-quality PS sheet production.

As a pioneer in PVB interlayer film production machine technology, we specialize in delivering cutting-edge systems designed for high-performance PVB interlayer film manufacturing. Our PVB interlayer film production machines are engineered to meet global industry standards, combining precision, efficiency, and sustainability.

FAQ

What is the main business of GWELL?

Can I go on a field trip to the GWELL factory?

What are the services for purchasing equipment at GWELL?

What types of plastic extrusion machines are available from GWELL?

What is APET PETG CPET Sheet Extrusion Line?

Where does GWELL ship from?

Are there any technical supports for extrusion machine that you need?

Our service will be always at your disposal over the entire extrusion line life.So if you want to know about any other technical supports.Please contact us as soon as possible.

Previous

下一页