ETFE Film Extrusion Line

ETFE film has the characteristics of heat resistance, self-cleaning, non-adhesion, high toughness and high ductility. These properties allow F-40 film to accommodate a variety of sizes and shapes during semiconductor packaging.

Key words:Sheet Extrusion Line

Category:

Solar Extrusion Line

Download:

Description

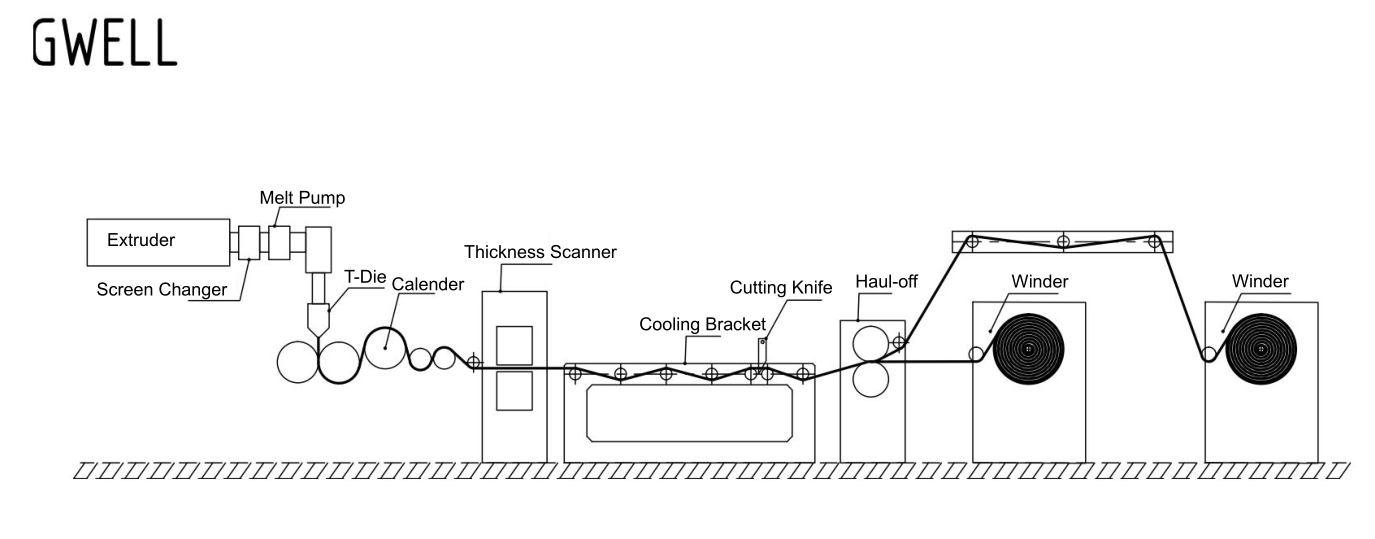

Process Flows

Extruder —- Screen changer —– Melt pump —– T-die —— Calender —– Thickness Scanner —-Cooling Bracket —-Cuttting Knife —- Haul-off —-Winder

Simple introduction of ETFE film raw material

- ETFE plastic- Ethylene tetrafluoroethylene

- Specific gravity: 1.7 g/cubic centimeter

- Molding shrinkage: 3.1-7.7%

- Molding temperature: 300-330 ℃

Physical property

- Long term use at a temperature of -80 to -220 degrees Celsius, it has excellent chemical corrosion resistance, is resistant to all chemicals, has the lowest friction coefficient among plastics, and has excellent electrical properties. Its electrical insulation is not affected by temperature, and is known as the “king of plastics”.

- Its chemical resistance is similar to that of PTFE, but better than PVDF.

- Its creep resistance and compressive strength are better than PTFE, its tensile strength is high, and its elongation can reach 100-300%. Good dielectric properties and excellent radiation resistance. 1. It is suitable for making corrosion-resistant parts, wear-reducing and wear-resistant parts, sealing parts, insulating parts and medical equipment parts.

- Wire and cable insulation, anti-corrosion equipment, sealing materials, pump valve bushings, and chemical containers.

ETFE Film performance

1. "The crystallization material exhibits low moisture absorption properties and can be transformed into products using standard thermoplastic processing techniques."

2. "The material exhibits low fluidity and is prone to decomposition, resulting in the release of corrosive gases upon breakdown. It is crucial to maintain a strict molding temperature that does not exceed 350 degrees Celsius. Additionally, the mold should be preheated to a range of 100 to 150 degrees Celsius, and the resistance within the pouring system to material flow should be minimized. This allows for the production of thin-walled, uncomplicated products with a thickness ranging from 0.7 to 0.8 mm."

3. "Transparent pellets can be processed through injection molding and extrusion molding techniques. The optimal molding temperature ranges from 300 to 330 degrees Celsius; exceeding 350 degrees may lead to discoloration or the formation of bubbles. For best results, high-speed and low-pressure molding methods are recommended, although it may pose challenges during the demolding process."

ETFE (F-40) fluoroplastics are obtained from DuPont in the United States and Asahi Glass in Japan, primarily for use in anti-corrosion linings. This material exhibits the exceptional corrosion resistance of polytetrafluoroethylene while also possessing strong adhesion properties to metals, effectively addressing the adhesion limitations typically associated with polytetrafluoroethylene. Additionally, its average linear expansion coefficient is comparable to that of carbon steel, making ETFE (F-40) an ideal composite material when combined with metals. Furthermore, it demonstrates outstanding resistance to negative pressure, enhancing its overall utility in various applications.

Application

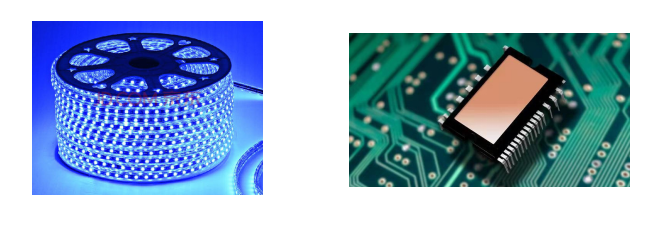

Dedicated for semiconductor package release

- Release film for printed circuit board

- Release film for semiconductor molding

Special for LED package release

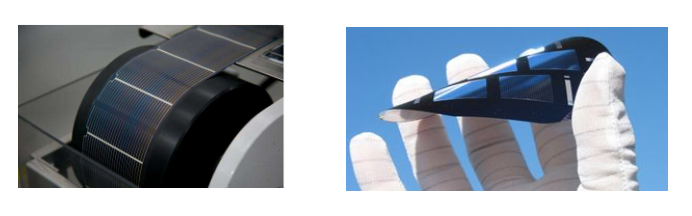

For solar photovoltaic

- Solar battery

- Fuel cell

architectural membrane material

- Membrane structure

- Covering materials for greenhouses

Other uses

- Soundproof material protection film

- Wallpaper Ceiling Protective Film

- Kitchen decoration film

◆ ETFE film Product description:

The ETFE film is distinguished not only by its remarkable heat resistance, self-cleaning abilities, and non-adhesive qualities but also by its impressive tenacity, ductility, and malleability. These exceptional attributes enable the F-40 film to be employed across a diverse array of applications, allowing it to adapt seamlessly to various sizes and shapes, particularly in semiconductor encapsulation. Beyond its durability and versatility, ETFE film is renowned for its outstanding optical clarity and its ability to withstand harsh environmental conditions, making it an ideal choice for rigorous industrial and technological applications. In summary, the unique blend of characteristics that ETFE film offers positions it as a superior material for a multitude of encapsulation and protective functions within the semiconductor industry.

◆ ETFE film Characteristics:

- High temperature resistance—can be used at 150°C-180°C

- Self-cleaning—low surface tension is not easy to get dirty and easy to clean

- Non-adhesive—the surface is smooth and pollution-free after release

- High ductility – large dimensional strain to meet the needs of different shapes of molds

- Chemical resistance – resistant to harsh conditions such as acids, alkalis, and chemicals

◆ ETFE film Performance Index:

| Density | Temperature tolerance | Tensile strength | Percentage of breaking elongation | surface roughness |

| 1.74g/cm3 | 200℃ | ≥45MPa | ≥300% | frosted 1.4 ± 0.2 µm; mirrored <0.3 µm |

◆ETFE film Standards(Customizable):

| Thickness | Width | Length | Surface treatment |

| 25 µm | 1250 mm | 500 m/roll | Frosted Mirrored |

| 50 µm | 1250 mm | 500 m/roll | |

| 60 µm | 1250 mm | 500 m/roll | |

| 75 µm | 1250 mm | 500 m/roll |

Special engineering film — special for LED package release

Product Description:

It has high temperature resistance, low surface tension self-cleaning, non-adhesive, high toughness and high ductility, and is suitable for LED packages of various shapes and sizes.

Feature:

- High temperature resistance—can be used at 150°C-180°C

- Self-cleaning—low surface tension is not easy to get dirty and easy to clean

- Non-adhesive—the surface is smooth and pollution-free after release

- High ductility – large dimensional strain to meet the needs of different shapes of molds

- Chemical resistance – resistant to harsh conditions such as acids, alkalis, and chemicals

Performance

| density | temperature tolerance | Tensile Strength | elongation at break | Transmittance |

| 1.74g/cm³ | 200℃ | ≥45MPa | ≥300% | 95% |

Specification

| thickness | width | length | surface treatment |

| 50um | 1250/1600mm | 500m/roll |

Matte treatment on the outer surface of the roll; mirror treatment on the inner surface |

| 75um | 1250/1600mm | 500m/roll | |

| 25um | 1250/1600mm | 1000m/roll |

Special engineering film — special for solar photovoltaic

Product Description:

This material boasts exceptional thermal resistance, making it perfectly suited for high-temperature applications. Moreover, its low surface tension facilitates effortless self-cleaning, reducing the need for regular maintenance. Thanks to its non-adhesive characteristics, it resists sticking to other surfaces, thereby minimizing the risk of damage or contamination. With remarkable toughness and ductility, this material can endure challenging conditions while preserving its structural integrity over time. Its versatility allows for use in semiconductor packages of various shapes and sizes, offering a dependable and long-lasting solution for electronic components.

Feature:

- High temperature resistance—can be used at -80°C-180°C

- Self-cleaning—low surface tension is not easy to get dirty and easy to clean

- Chemical resistance – resistant to harsh conditions such as acids, alkalis, and chemicals

- High light transmittance—light transmittance over 95%

- Long life—the service life of the natural state is more than 30 years

- Anti-PID—volume resistivity up to 1017

◆ETFE film Performance Index:

| Density | Temperature tolerance | Tensile strength | Surface tenson | Transmittance |

| 1.74g/cm3 | -80~200℃ | ≥45MPa | >42dyne | 95% |

◆ ETFE film Standards(Customizable):

| Thickness | Width | Length | Surface treatment |

| 20 µm | 1250 mm | 3000m/roll | Mirrored Corona |

| 50 µm | 1250 mm | 1500m/roll | |

| 100 µm | 1250 mm | 500m/roll |

Special engineering film — special for building material film

Product Description:

It is important to highlight that this material demonstrates remarkable resistance to elevated temperatures, enabling it to endure extreme conditions while maintaining its structural integrity. Additionally, its low surface tension facilitates effortless self-cleaning, rendering it perfect for applications where hygiene is paramount. Furthermore, its non-adhesive characteristics prevent it from adhering to other surfaces, thereby minimizing the risk of contamination. Moreover, its exceptional toughness and ductility contribute to its durability and flexibility, allowing it to conform to a wide range of shapes and sizes in semiconductor packaging.

Feature:

- High temperature resistance – can be used at -80°C-180°C

- Self-cleaning – low surface tension is not easy to get dirty and easy to clean

- Chemical resistance – resistant to harsh conditions such as acids, alkalis, and chemicals

- High light transmittance – light transmittance above 95%

- Long life – natural state service life of more than 30 years

◆ ETFE film Performance Index:

| Density | Temperature tolerance | Tensile strength | Percentage of breaking elongation | Transmittance |

| 1.74g/cm3 | -80~200℃ | ≥45MPa | ≥300% | 95% |

◆ ETFE film Standards(Customizable):

| Thickness | Width | Length | Surface treatment |

| 200μm | 1250mm | 500m/roll | Mirrored |

| 100μm | 1250mm | 500m/roll |

| NO. | project | Testing Standard | unit | index |

| 1. | thickness | ASTM-D-882 | μm | 25-100 |

| 2. | density | ASTM-D-792 | g/cm³ | 1.73 ±0.02 |

| 3. | Transmittance | GB/T2410-2008 | % | ≥93 |

| 4. | Haze | GB/T2410-2008 | % | <5 |

| 5. | elongation at break | ASTM-D-882 | MD (%) | >300 |

| TD (%) | >300 | |||

| 6. | tensile strength | ASTM-D-882 | MD ( Mpa) | >50 |

| TD ( Mpa) | >45 | |||

| 7. | Elastic Modulus | ASTM-D-882 | Mpa | >500 |

| 8. | tear strength | ASTM-D-1922 | MD ( Mpa) | >300 |

| TD ( Mpa) | >400 | |||

| 9. | Impact strength | ASTM-D-256 | m | >200 |

| 10. | Shore hardness | ASTM-D-2240 | M | 68-78 |

| 11. | water absorption | ASTM-D-570 | % | <0.001 |

| 12. | recommended temperature | – | ℃ | -80-220 |

| 13. | Dielectric constant | ASTM-D-150 | – | <1.8 |

| 14. | volume resistance | ASTM-D-257 | Ω .cm | >6.0*1017 |

| 15. | flame retardant | ASTM-D-2863 | UL-94 | V-O |

| 16. | water vapor transmission rate | GB/T26253-2010 | g/(m² 。24h) | <20 |

| 17. | thermal stability | TD2.9%,MD | ||

| TD,MD out of shape< 1%150℃ 30min(200℃ 30min) | ||||

| 18. | Surface Tension | <18 Dyne ( mN/m) | ||

Other uses

a.Sound insulation material protective film

b.Wallpaper ceiling protective film

c.Kitchen decorative film

Parameter

ETFE film Standards(Customizable):

Thickness Width Length Surface treatment

25 µm 1250 mm 500 m/roll Frosted Mirrored

50 µm 1250 mm 500 m/roll

60 µm 1250 mm 500 m/roll

75 µm 1250 mm 500 m/roll

Application

1.Semiconductor Packaging Release Special

2.Release film for printed circuit boards

3.Release film for semiconductor molding

4.LED packaging release specific

Client

About Gwell

Innovation drives enterprise progress. Relying on the group’s strong technology, equipment strength and innovation spirit, Gwell is committed to the development of high-tech products and the international market. Gwell also actively exchanges and cooperates with world-class scientific research institutions. The new technologies, new processes and new products developed by Gwell are widely used in building materials(PP hollow sheet extrusion machine, PC optic extrusion machine), home appliances(SPC floor extrusion machine), packaging(PET sheet extrusion machine, EVOH film extrusion machine),

medical treatment(PVC rigid sheet extrusion machine), automobiles(TPU film extrusion machine, PVB film extrusion machine), new energy(EVA solar film extrusion machine), aerospace(TPU film extrusion machine), rail transit(waterproof film extrusion machine) and other fields, which are closely related to human life.

Related Product

The main components of the PC Sheet extrusion production line are selected from the world’s high-quality products (such as screws, barrels, rollers, etc.), and its production process is comprehensive. As an excellent supplier of plastic extruders, GWELL’s complete set of production line has approached the world’s high-quality product standards.

As a premier Chinese manufacturer of plastic extrusion machinery, GWELL delivers cutting-edge PS (Polystyrene) Sheet Extrusion Lines engineered for precision, efficiency, and unmatched product consistency. Our advanced extrusion systems are designed to meet the rigorous demands of diverse industries, offering tailored solutions for high-quality PS sheet production.

As a pioneer in PVB interlayer film production machine technology, we specialize in delivering cutting-edge systems designed for high-performance PVB interlayer film manufacturing. Our PVB interlayer film production machines are engineered to meet global industry standards, combining precision, efficiency, and sustainability.

FAQ

What is the main business of GWELL?

Can I go on a field trip to the GWELL factory?

What are the services for purchasing equipment at GWELL?

What types of plastic extrusion machines are available from GWELL?

What is APET PETG CPET Sheet Extrusion Line?

Where does GWELL ship from?

Are there any technical supports for extrusion machine that you need?

Our service will be always at your disposal over the entire extrusion line life.So if you want to know about any other technical supports.Please contact us as soon as possible.

Previous