PP PE PVC ABS PVDF Board Extrusion Line

GWELL as China Plastic Extruder Supplier, 500W PP PE PVC ABS PVDF board extrusion line, simple and convenient operation and maintenance, fast speed, high precision, can effectively improve production efficiency, change traditional production methods, and make rational use of plates.

Key words:Sheet Extrusion Line

Category:

Board Extrusion Line

Download:

Description

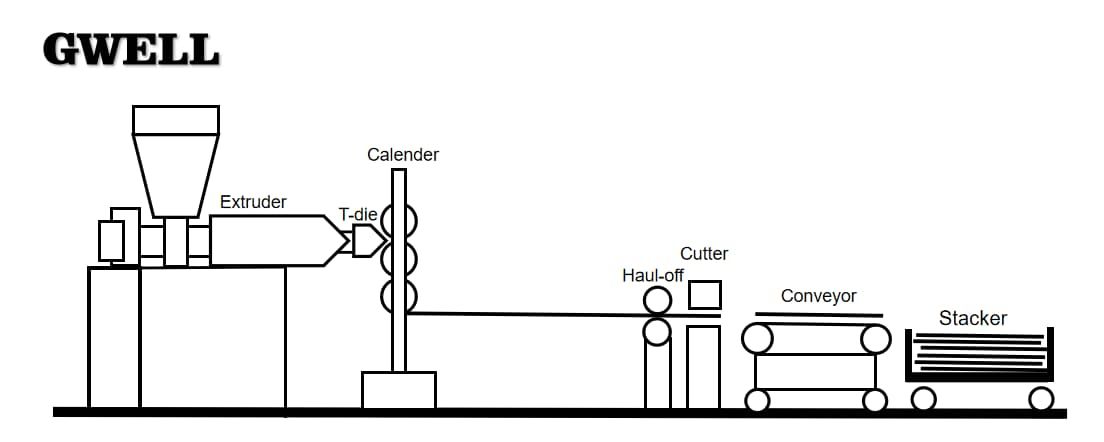

PP PE PVC ABS PVDF board extrusion line Process Flows

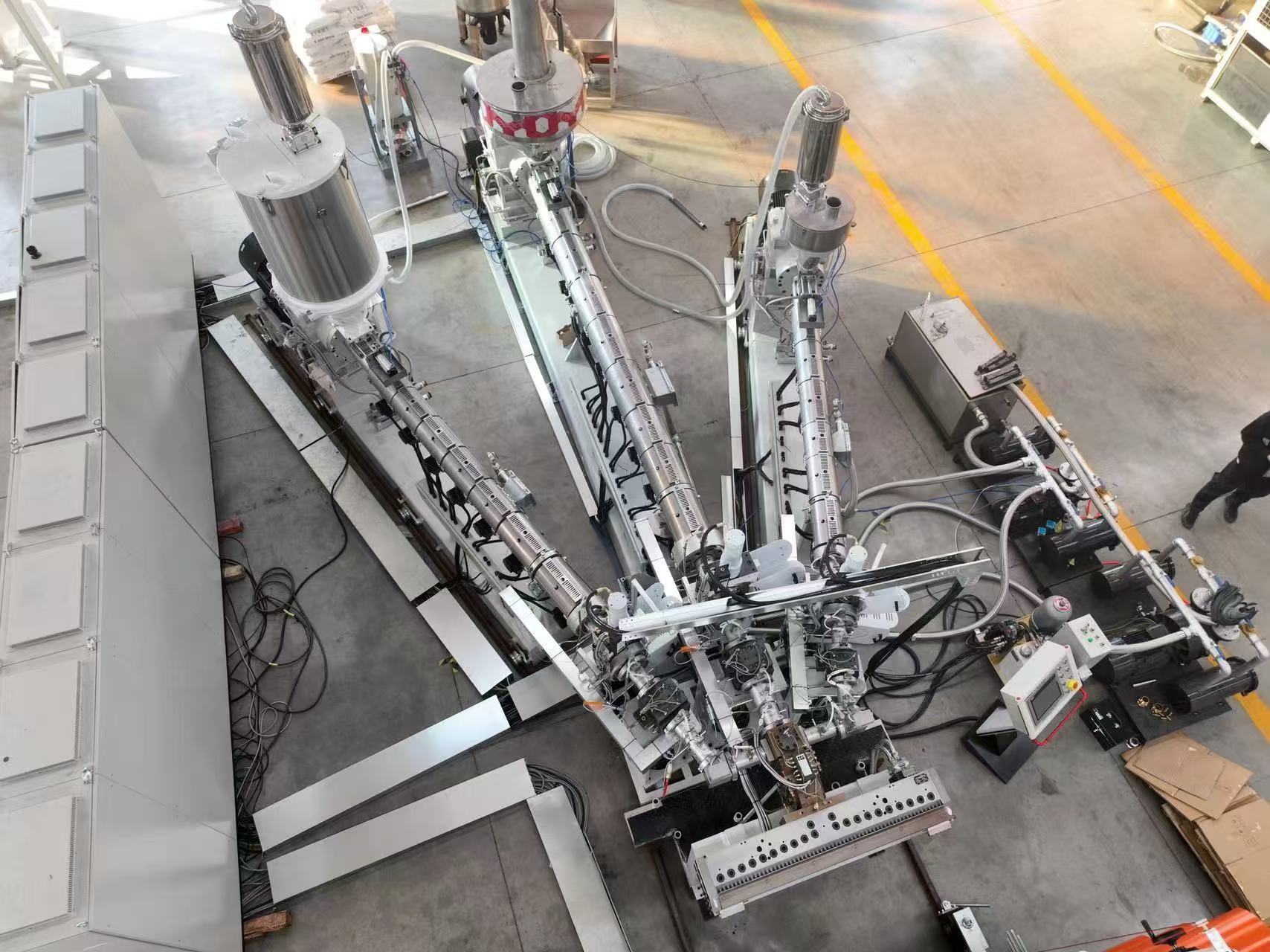

PP PE PVC ABS PVDF board extrusion line Extruder: GWELL as China Plastic Extruder manufacturer, choose single-screw extruder (vented or unvented) according to different materials. The screw adopts special mixing function and precise temperature control system to ensure high plasticization, high output and stable extrusion of plastic.

Temperature control ± 1 ℃ can accurately control the plasticizing process and plate thickness and flat shaping.

Screen change and mold: hydraulic quick screen change device ensures that there is no material leakage and the screen change is fast and effective; According to different materials, different structural forms are selected for the die. The clothes hanger die head adopts the double section flow design of page number, which is convenient for adjusting the uniform flow distribution, and the thickness adjustment of extruded plate is more accurate.

Three roller calender: 45 ° inclined three roller or vertical three roller or horizontal three roller calender is adopted according to the thickness of the plate. The three roller temperature control is independent of each other, the roller gap can be adjusted freely, and the special design of adjustable angle of the middle roller ensures the calendering effect and the thickness uniformity of the plate (sheet).

Plate thickness control adopts screw adjustment and two-way adjustment of pressing wheel, which can accurately control plate thickness. The independently controlled roller temperature control system can accurately control the temperature of the pressing roller barrel to make the thickness of the plate uniform.

Cooling roller support: equipped with corresponding cooling guide roller to make the cooling effect better. In addition, it is equipped with edge cutting device to ensure the fixed width and edge quality of the plate.

Transverse cutting machine: it is used for fixed length cutting, with cutting accuracy less than 2mm. Alloy blade or hard alloy saw blade is used, which is synchronized with the plate during cutting, so as to ensure the cutting quality of the plate and the long-term stability of cutting action.

PP PE PVC ABS PVDF board extrusion line Winder: it adopts high torque motor and friction winding, which can adjust the speed and winding tension at will, and can also provide other forms of winding according to the needs of users.

Parameter

| Extruder Type | single screw extruder GWS120 | single screw extruder GWS150 | single screw extruder GWS180 |

| Raw material | ABS, PP, PE, PVDF | ||

| Net width | 1200mm | 1800mm | 2000mm |

| Thickness range | 3-50mm | ||

| Capacity | 300-400kg/h | 450-550kg/h | 500-700kg/h |

Application

PP thick plate production line: PP thick plate is widely used in chemical industry, food industry, anti-corrosion industry, purification industry, environmental protection equipment production industry.

PE thick plate production line: polyethylene (HDPE) plate is widely used in chemical industry, electric power and other industries. HDPE board can also be used as engineering plastics in machinery, chemical equipment, widely used in the manufacture of ice court wall board.

ABS thick plate production line: ABS thick plate is widely used in home appliances, electronics, packaging, medical devices and other industries, and also widely used in the field of plastic suction.

PVDF plate production line: PVDF plate is a pure plate formed by high temperature extrusion with polyvinylidene fluoride resin. The extrusion process does not contain additives (such as uv stabilizer, heat stabilizer, softener, lubricant or flame retardant). It is widely used in petrochemical, electric power, metallurgy, papermaking, textile, pharmaceutical and atomic energy industries and many other industrial fields, especially suitable for pure water system and semiconductor industry in the transmission of pure chemical reagent.

PVC thick plate, transparent plate production line: hard PVC thick plate is widely used in chemical industry, petroleum, electroplating, water purification treatment equipment, environmental protection equipment, mines, medical electronics, communications, anti-corrosion containers, equipment electrical protection cover, light box, advertising decoration and other industries.

Client

About Gwell

Innovation drives enterprise progress. Relying on the group’s strong technology, equipment strength and innovation spirit, Gwell is committed to the development of high-tech products and the international market. Gwell also actively exchanges and cooperates with world-class scientific research institutions. The new technologies, new processes and new products developed by Gwell are widely used in building materials(PP hollow sheet extrusion machine, PC optic extrusion machine), home appliances(SPC floor extrusion machine), packaging(PET sheet extrusion machine, EVOH film extrusion machine),

medical treatment(PVC rigid sheet extrusion machine), automobiles(TPU film extrusion machine, PVB film extrusion machine), new energy(EVA solar film extrusion machine), aerospace(TPU film extrusion machine), rail transit(waterproof film extrusion machine) and other fields, which are closely related to human life.

Related Product

The main components of the PC Sheet extrusion production line are selected from the world’s high-quality products (such as screws, barrels, rollers, etc.), and its production process is comprehensive. As an excellent supplier of plastic extruders, GWELL’s complete set of production line has approached the world’s high-quality product standards.

As a premier Chinese manufacturer of plastic extrusion machinery, GWELL delivers cutting-edge PS (Polystyrene) Sheet Extrusion Lines engineered for precision, efficiency, and unmatched product consistency. Our advanced extrusion systems are designed to meet the rigorous demands of diverse industries, offering tailored solutions for high-quality PS sheet production.

As a pioneer in PVB interlayer film production machine technology, we specialize in delivering cutting-edge systems designed for high-performance PVB interlayer film manufacturing. Our PVB interlayer film production machines are engineered to meet global industry standards, combining precision, efficiency, and sustainability.

FAQ

What is the main business of GWELL?

Can I go on a field trip to the GWELL factory?

What are the services for purchasing equipment at GWELL?

What types of plastic extrusion machines are available from GWELL?

What is APET PETG CPET Sheet Extrusion Line?

Where does GWELL ship from?

Are there any technical supports for extrusion machine that you need?

Our service will be always at your disposal over the entire extrusion line life.So if you want to know about any other technical supports.Please contact us as soon as possible.