PC PMMA Optical Sheet Extrusion Line

GWELL as China Plastic Extruder manufacturer, The PC/PMMA extrusion line equipment manufactured by GWELL, has advantages in energy consumption, intelligence, automation indicators, safety standards, process standards, etc. replaces imported equipment, but it has cost-effective advantages.

Key words:Sheet Extrusion Line

Category:

Sheet Extrusion Line

Download:

Description

PC/PMMA optical sheet extrusion line Introduce

The extruder utilized in the PC PMMA Optical Sheet Extrusion Line features a specialized mixing function and a high-speed plasticizing design aimed at minimizing the occurrence of crystal points. The T-type model is engineered with a unique double-section structure for the PC PMMA composite panel, allowing for both coarse adjustments and fine-tuning to achieve precise plate thickness adjustments. Manufactured by China GWELL, the PC/PMMA extrusion line equipment boasts numerous advantages, including energy efficiency, advanced intelligence, automation capabilities, and adherence to safety and process standards. This innovative equipment serves as a cost-effective alternative to imported models. Additionally, the temperature control of the three roller calendars is maintained within a precision of ± 1 ℃, ensuring accurate regulation of the plasticization process, as well as the thickness, flatness, and surface quality of the plates. Various types of three roller calendars are selected based on the specific materials used, enhancing the overall production process.

The PC PMMA Optical Sheet Extrusion Line is outfitted with a sophisticated precision thickness gauge and an automated thickness control system, guaranteeing that the sheets produced are uniform and of superior quality. Additionally, the line features an advanced cooling system that rapidly cools the sheets, effectively preventing any warping or distortion.

Moreover, the PC PMMA Optical Sheet Extrusion Line is equipped with state-of-the-art automation functionalities, including remote monitoring and control options. These features enable operators to effortlessly oversee and modify the production process, thereby enhancing both efficiency and productivity. Furthermore, the design prioritizes safety, incorporating elements such as emergency stop buttons and protective guards to safeguard operators from potential risks.

In summary, the PC PMMA Optical Sheet Extrusion Line developed by China GWELL represents a state-of-the-art solution for the production of premium optical sheets tailored for a wide range of applications. Featuring advanced technology, an energy-efficient design, and cost-effective benefits, this extrusion line stands as a significant investment for manufacturers aiming to elevate their production capabilities and effectively respond to market demands.

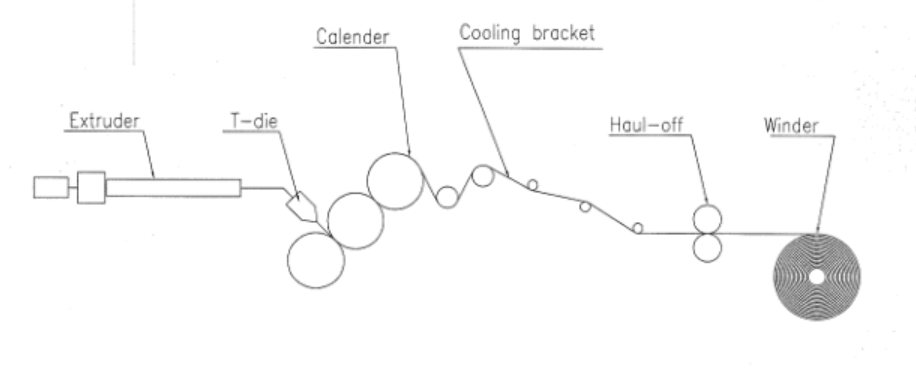

PC PMMA Optical Sheet Extrusion Line Process Flows

Extruder —- Screen changer —– Melt pump —– T-die —— Calender —– Cooling bracket —– Haul-off—- Winder

Feature of PC/PMMA optical sheet extrusion line by China Gwell

1. The extrusion part, precise melt pump system, and T-die ensure the even and stability of the melt and the optical function of the PC/PMMA sheet.

2. The precise three-roll calendar system provides a guarantee for the mechanical and physical function of the sheet.

3. A thickness scanner can monitor the thickness of the sheet and feedback in real-time.

4. Accumulator and tension monitoring device to ensure high-speed operation of the whole line and improve efficiency.

5. The updated high-speed automatic winder with an automatic correction system can automatically complete the winding and cutting, and the winding end surface is neat.

Usage of PC, PMMA optical sheet

- PC optical sheet products are mainly used in the automobile industry.

- Thin-film switch for electronics and electrical industry.

- Computer, mobile phone, commercial LCD.

- Sunglasses, sun hat, plating mirror, protective mask; Special printing.

- The instrument is utilized in a variety of applications, including the examination of dishes, piping systems, insurance glass, writing pads, and components of slide show projection equipment. Its usage extends broadly across sectors such as machinery, electronics, automotive, and construction supplies. Furthermore, it is rapidly making inroads into advanced fields like aviation, aerospace, computing, CDs, optical fibers, and numerous other high-tech domains. Additionally, the instrument finds applications in greenhouse environments, tunnel lighting, garden aesthetics, and recreational areas, serving as distinctive decoration for spaces like galleries, pavilions, booths, and advertising signage. It is also employed in lightbox advertising displays and exhibition layouts, as well as in wall and roof constructions. High-quality interior decoration materials, such as noise barriers along highways and urban roads, agricultural and breeding greenhouses, engineering noise control solutions, and ceiling lighting, are other areas where this instrument is valuable. The building materials industry, industrial products, and security measures—including anti-theft and bulletproof facilities—also benefit from its versatility. Other applications include electronic display LED baffles, resin boards, basketball backboards, transparent aviation containers, and components for motorcycles, aircraft, trains, ships, automobiles, steamships, submarines, and glass shields used by military and police forces, along with medical packaging.

Parameter

| Type | PC optical sheet extrusion line | PMMA optical sheet extrusion line |

| Width of Products | 600mm-1220mm | 600mm-1220mm |

| Thickness of Products | 0.125mm-2mm | 0.6mm-3mm |

| Output | 200kg/h-450kg/h | 300kg/h-550kg/h |

| Type of extrusion line | single screw sheet GAG extrusion line | twin screw venting GAG sheet extrusion line | ||

| Extrusion type | Co-extruded | |||

| Finished Product | three-layer sheet | |||

| Raw material | PETG-APET-PETG | |||

| Net width | 600mm-1220mm and more | |||

| Thickness range | 0.15mm-2mm and more | |||

| Capacity | 200kg/h-1200kg/h and more | |||

| Application | Food and fruit packing,Electronic components packing,Printing ,Furniture surface and more | |||

Application

China Plastic Extruder Supplier-GWELL Products PC PMMA Optical Sheet Extrusion Line

General application: Film switch of electronics, LCD for computer, Mobile, Sunglass, Helmet, Special printing, Medicine packing, Electronic instrument display components, Electronic flame-retardant components, Liquid crystal displays, Mobile phone protective the PC/PMMA extrusion line equipment manufactured by GWELL, which has advantages in energy consumption, intelligence, automation indicators, safety standards, process standards, and etc., replaces imported equipment, but it has cost-effective advantages.lms, etc.

Client

About Gwell

Innovation drives enterprise progress. Relying on the group’s strong technology, equipment strength and innovation spirit, Gwell is committed to the development of high-tech products and the international market. Gwell also actively exchanges and cooperates with world-class scientific research institutions. The new technologies, new processes and new products developed by Gwell are widely used in building materials(PP hollow sheet extrusion machine, PC optic extrusion machine), home appliances(SPC floor extrusion machine), packaging(PET sheet extrusion machine, EVOH film extrusion machine),

medical treatment(PVC rigid sheet extrusion machine), automobiles(TPU film extrusion machine, PVB film extrusion machine), new energy(EVA solar film extrusion machine), aerospace(TPU film extrusion machine), rail transit(waterproof film extrusion machine) and other fields, which are closely related to human life.

Related Product

The main components of the PC Sheet extrusion production line are selected from the world’s high-quality products (such as screws, barrels, rollers, etc.), and its production process is comprehensive. As an excellent supplier of plastic extruders, GWELL’s complete set of production line has approached the world’s high-quality product standards.

As a premier Chinese manufacturer of plastic extrusion machinery, GWELL delivers cutting-edge PS (Polystyrene) Sheet Extrusion Lines engineered for precision, efficiency, and unmatched product consistency. Our advanced extrusion systems are designed to meet the rigorous demands of diverse industries, offering tailored solutions for high-quality PS sheet production.

As a pioneer in PVB interlayer film production machine technology, we specialize in delivering cutting-edge systems designed for high-performance PVB interlayer film manufacturing. Our PVB interlayer film production machines are engineered to meet global industry standards, combining precision, efficiency, and sustainability.

FAQ

What is the main business of GWELL?

Can I go on a field trip to the GWELL factory?

What are the services for purchasing equipment at GWELL?

What types of plastic extrusion machines are available from GWELL?

What is APET PETG CPET Sheet Extrusion Line?

Where does GWELL ship from?

Are there any technical supports for extrusion machine that you need?

Our service will be always at your disposal over the entire extrusion line life.So if you want to know about any other technical supports.Please contact us as soon as possible.